Cutting insert for high-efficient cutting

一种插入件、高效的技术,应用在用于车床的刀具、刀夹的附件、切削刀片等方向,能够解决切割插入件强度降低、切割刃数目有限、切割插入件损坏等问题,达到使用寿命和经济效率增加、提高材料去除速率、高生产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The above and other objects, features and advantages of the present invention will be more clearly understood through the following detailed description.

[0037] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0038] Reference is now made to the drawings, wherein like reference numerals represent the same or similar parts throughout the different drawings. Also, in the description of the present invention, in order to more clearly introduce the gist of the present invention, detailed descriptions of well-known techniques and structures will be omitted.

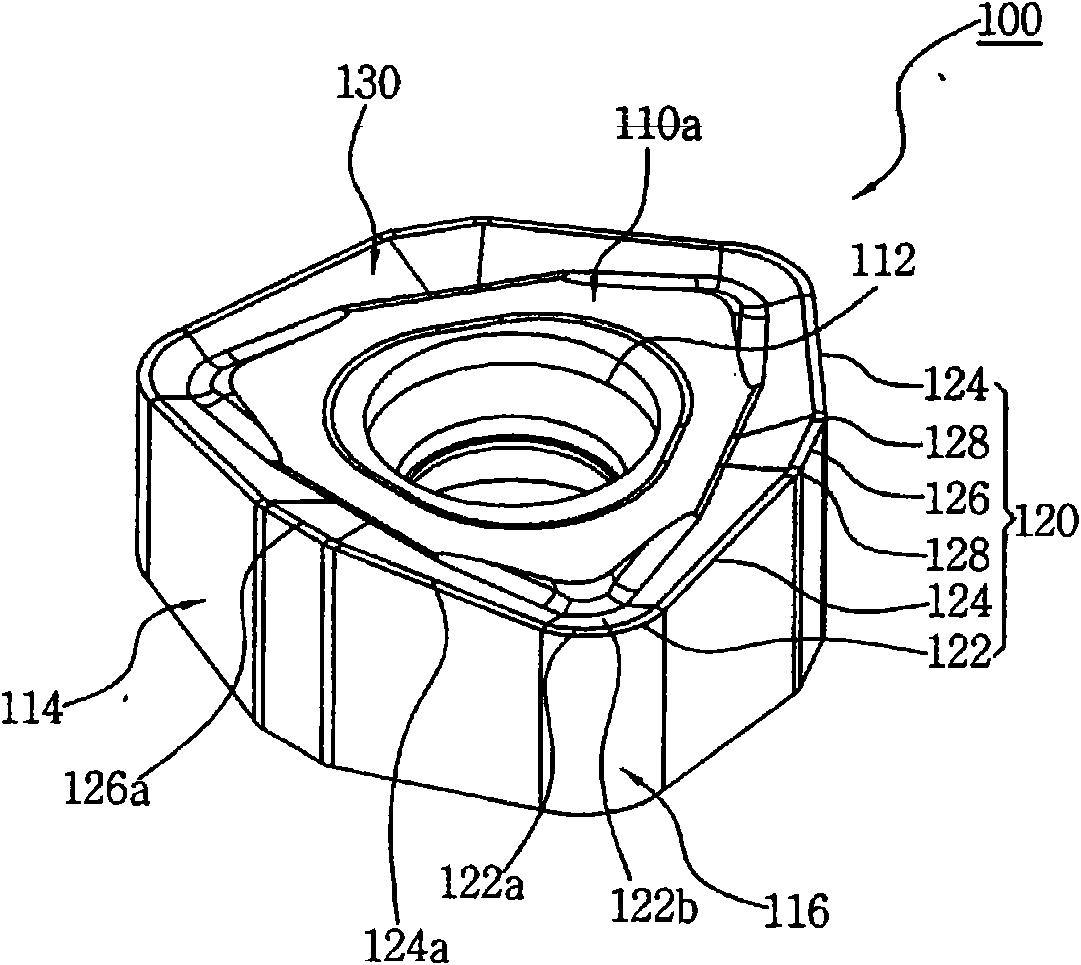

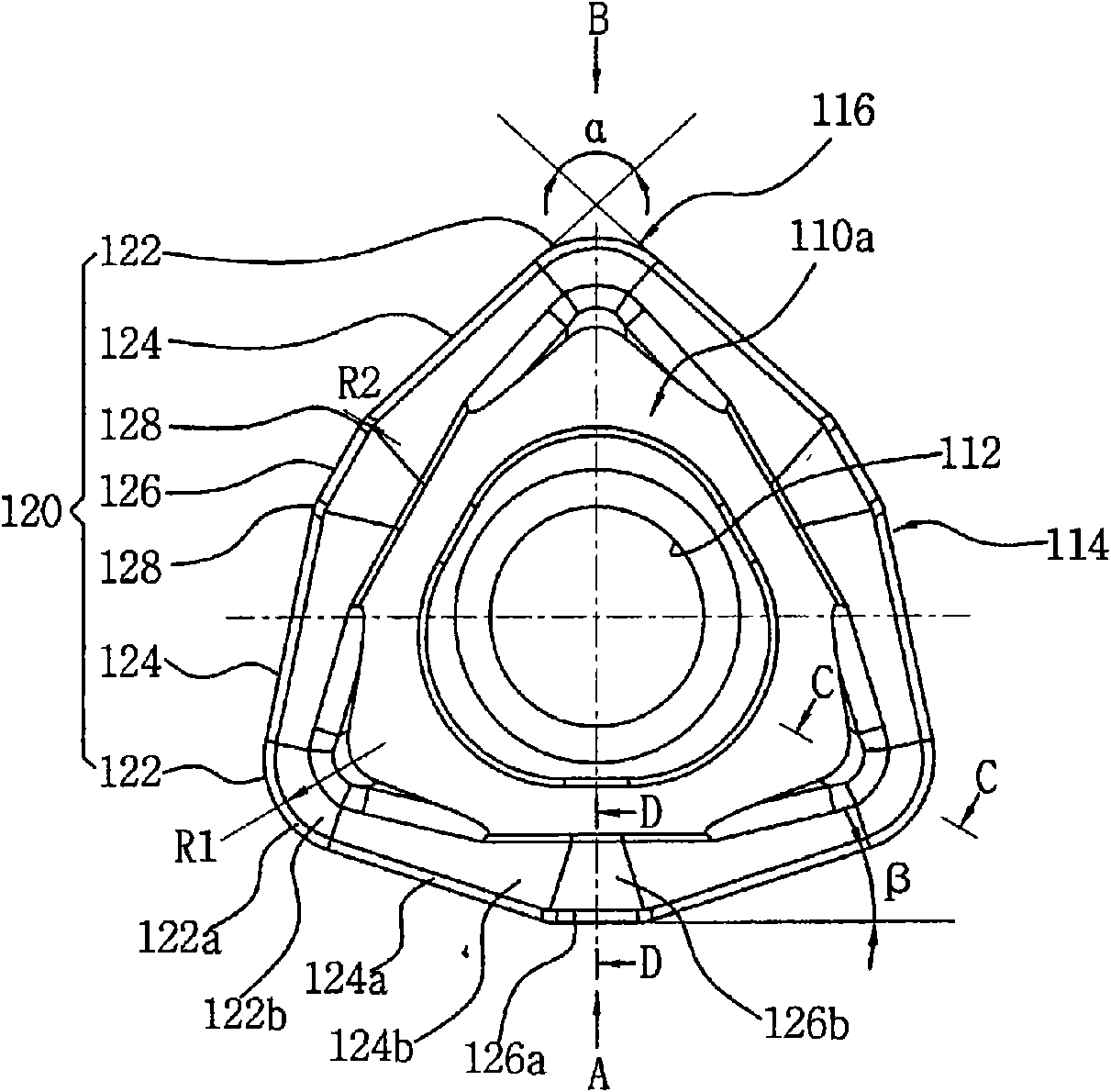

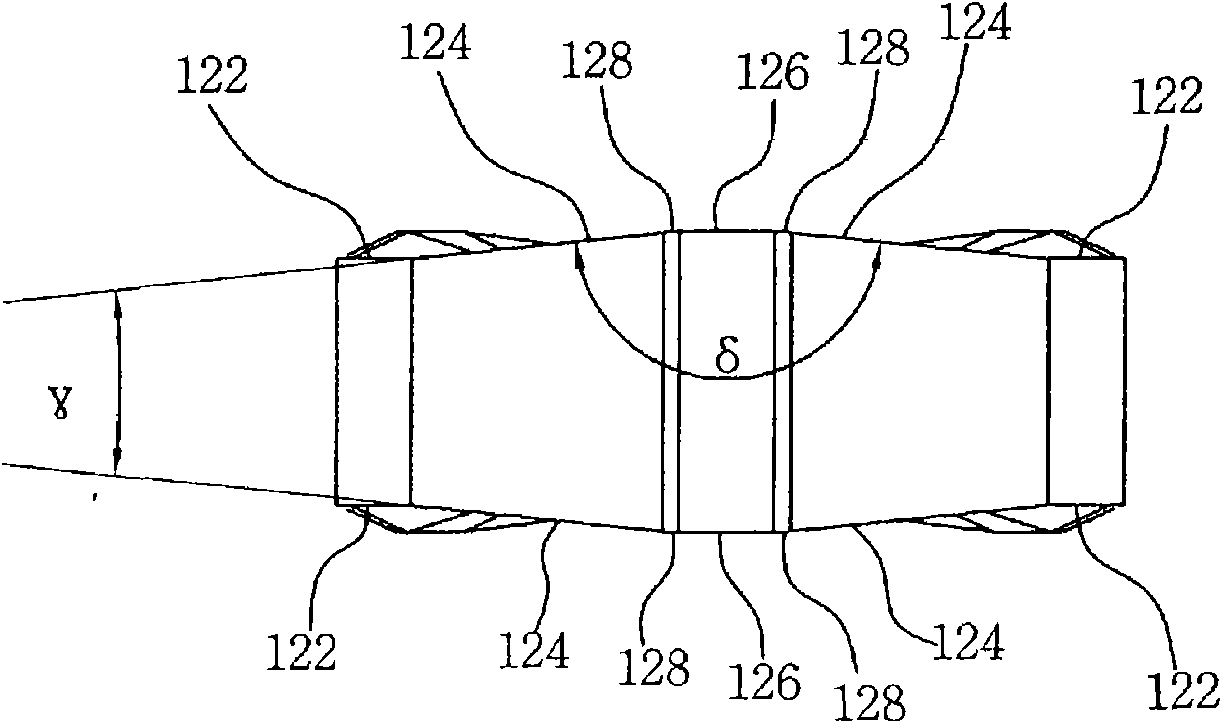

[0039] figure 1 is a perspective view of a cutting insert for efficient cutting according to the present invention. figure 2 yes figure 1 Plan view of the cutting insert. image 3 is to indicate that the cutting insert is made from figure 2 The view when looking in the direction indicated by the letter "A". Figure 4 is to indicate that the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com