Method for temperature drift compensation for film body acoustic wave oscillator and circuit

A thin-film bulk acoustic wave, temperature drift technology, applied in the field of microelectronics, can solve problems such as system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] A film bulk acoustic oscillator (FBAR) is a sandwich structure composed of a piezoelectric film layer and upper and lower plates, which can be used as an oscillator, filter, mass sensor, etc.

[0066] The FBAR oscillating circuit generally includes an FBAR device and a radio frequency voltage source. The RF voltage source applies RF voltage to the upper and lower electrodes of the FBAR, and the FBAR oscillates, and its resonant frequency is determined by the thickness of the piezoelectric film. The calculation formula is:

[0067] F ≈ v 2 d - - - ( 1 )

[0068] where F is the FBAR resonant frequency,

[0069] v is the sound velocity of the piezoelectric layer,

[0070] d is the thickness of the piezoelectric layer.

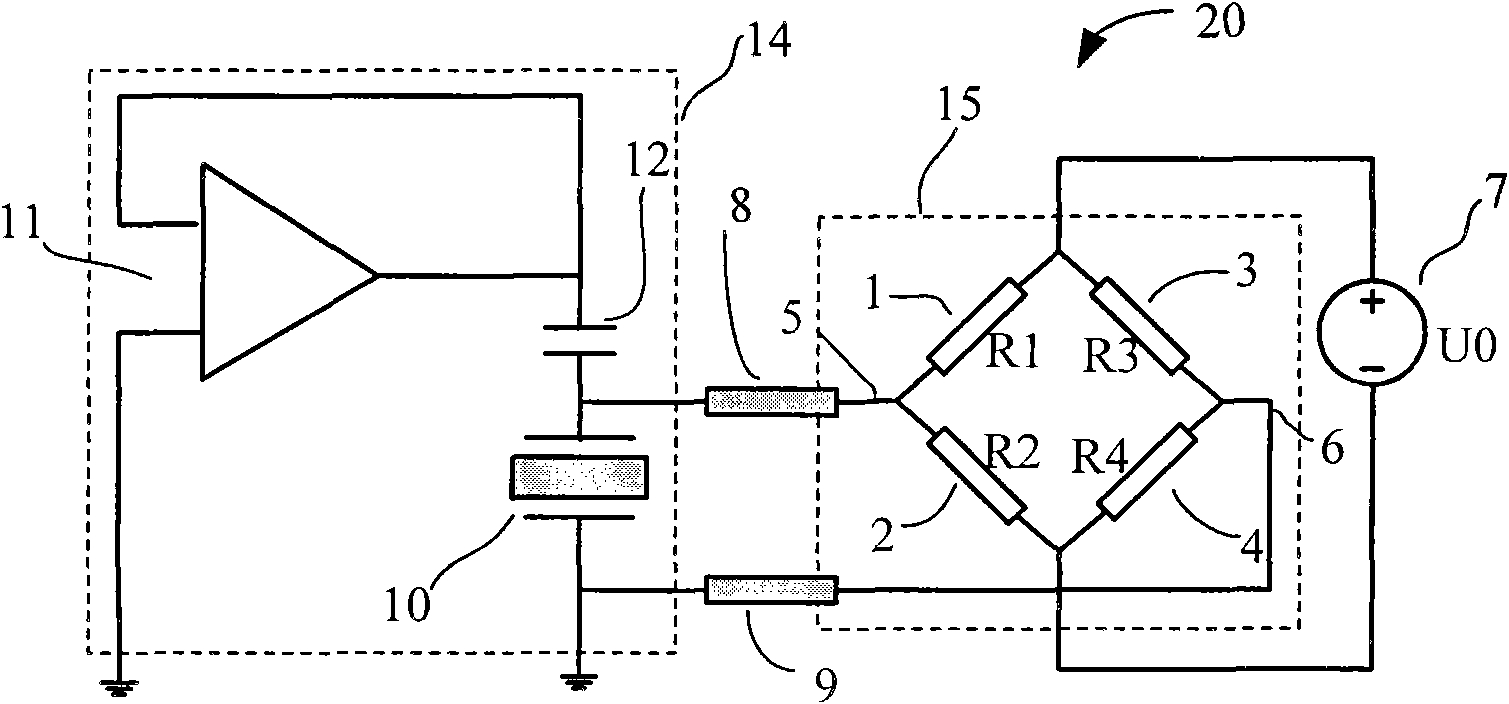

[0071] figure 1 Taking a simple FBAR oscillating circuit 20 as an example, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com