Movable asphalt cold regeneration cement gravel mixing building

A cold regeneration and mobile technology, applied in roads, road repairs, roads, etc., can solve problems such as high cost, environmental pollution, and consumption, and achieve the effects of saving materials and costs, preventing dust from flying, and reducing mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

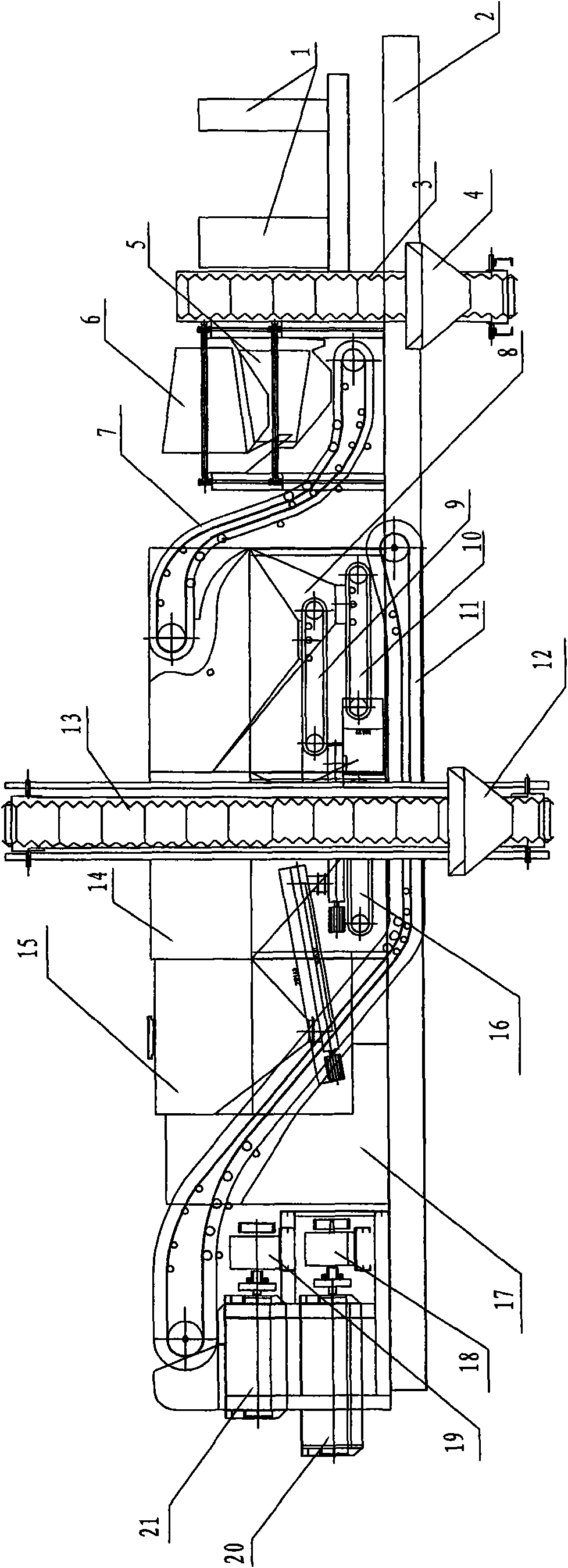

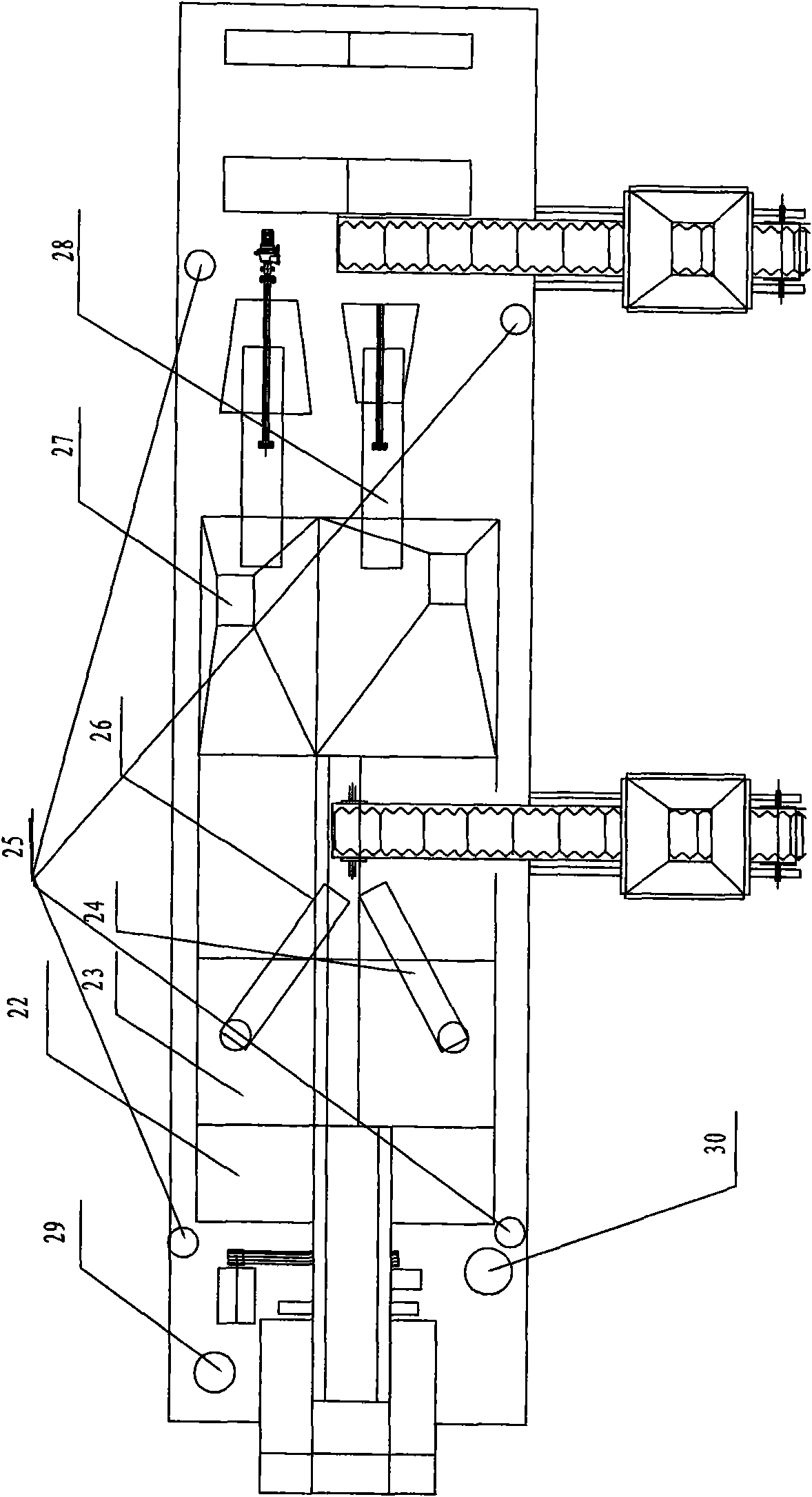

[0010] figure 1 , figure 2 The preferred solution of the present invention in use state is shown. The mobile asphalt cold recycled cement gravel mixing building of the present invention has a feeding device consisting of a milling and planing material feeding belt (3), a milling and planing material feeding hopper (4), a new aggregate feeding belt (13) and a new The aggregate upper hopper (12) is composed of an asphalt cold recycled cement gravel mixing device, which is composed of a lifting hook (25) arranged on the frame (2), a control cabinet (1), and the control cabinet (1). Connected milling material fine material weighing belt (10) and milling material coarse material weighing belt (9), fresh aggregate weighing belt (16), mineral powder metering auger (26), cement metering auger (24) , and milling material fine material screen (6) and milling material coarse material screen (5), milling material fine material bin (8) and milling material coarse material bin (27), ore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com