Single-ended fluorescent lamp slice pipe bending and molding device

A fluorescent lamp sheet and molding device technology, which is applied in glass molding, glass remolding, and glass manufacturing equipment, etc., can solve the problems of increased scrap rate, low production efficiency, and reduced molding speed, so as to save waste and improve production. The effect of improving the efficiency and the pass rate of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

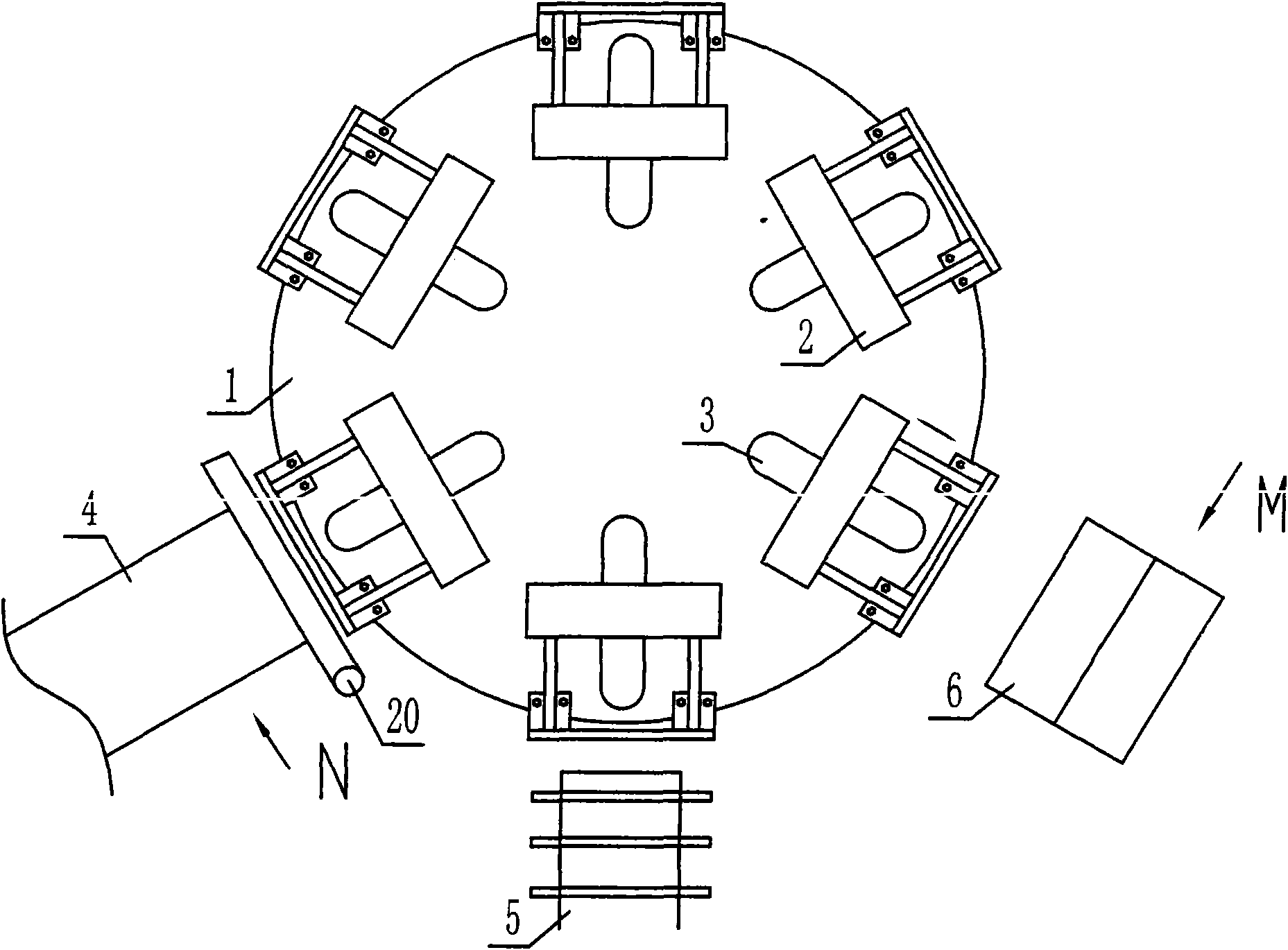

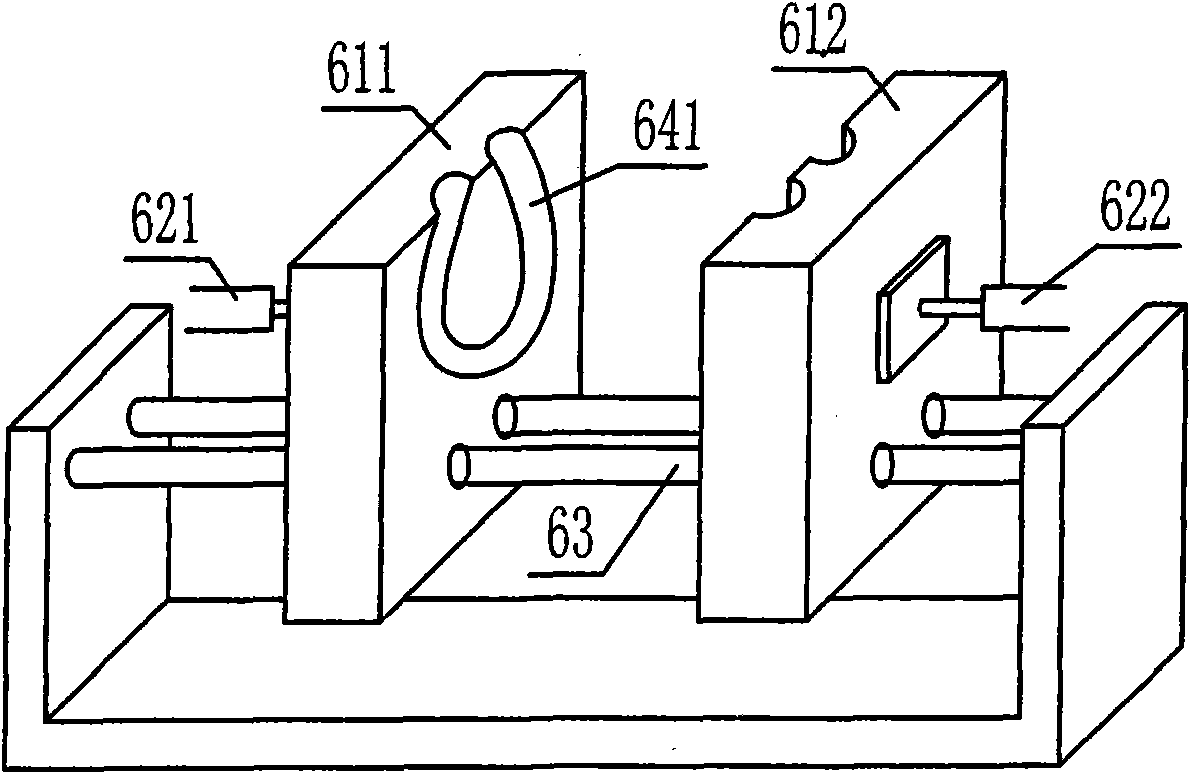

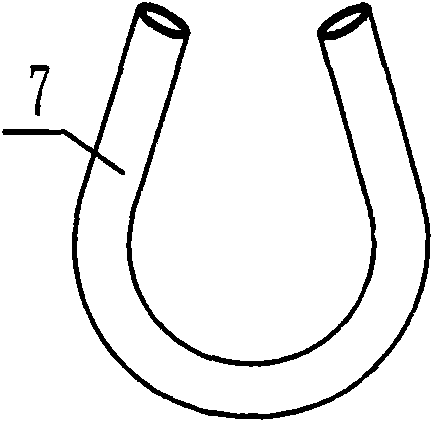

[0033] Embodiment 1: Referring to the accompanying drawings (except 15, 16, and 17), the single-ended fluorescent lamp tube bending device of the present invention includes a gap rotating turntable 1, and several sets of manipulator assemblies 2 are evenly distributed on the circumference of the turntable (6 sets in the figure, Depending on the size of the turntable area), each manipulator position of the turntable has radial guide grooves 3 for the manipulators to move radially forward and backward. There are glass tube heating and softening devices 5 arranged adjacently outside the turntable, and the molds can be separated / matched 6 for shaping, and The unloading tube receiving device 4 after the forming of the back. Shaping mold 6 ( figure 2 ), the same as the prior art, is composed of two templates 611, 612 that move toward each other according to the guide rail 63 and can be combined / separated. The matching surface is processed with a lamp tube shaping groove 641. The m...

Embodiment 2

[0035] Example 2: see Figure 15 , as embodiment 1, drive two manipulators to rotate oppositely to close up the elbow, separate to take over, can be fixed on the side-by-side gear 22,23 of two manipulators one end by a lifting rack 21 meshing up and down. It becomes a rack for lifting up and down, and at the same time drives the two gears that mesh with each other to rotate in opposite directions, so that the pipe bending manipulator fixed on the gears rotates in opposite directions to close the pipe bend / release the connecting pipe. In addition, it can also realize the closing / undrawing of the manipulator through, for example, a cam driving a connecting rod.

Embodiment 3

[0036] Embodiment 3: see Figure 16 , as mentioned above, the mold cavity 31 of the shaping die 6 can be a vertically curved structure according to the requirements of bending the sheet tube. Drive mold to separate / close power, also can be the rotating cam 19 that turntable rotates power output, the crank arm connecting rod 30 that makes sliding contact with it moves apart / closes.

[0037] In addition, the sizing mold 6 can also be set at the same station of the glass tube heating and softening device. Separately drop back into position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com