Method for catalytically oxidizing elemental mercury by oxidant controlledly released by porous ceramic membrane

A porous ceramic membrane, controlled release technology, applied in the environmental and chemical fields, can solve the problems of waste, increased removal rate, low HCl content, etc., to achieve the effect of improving oxidation efficiency and inhibiting a large amount of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

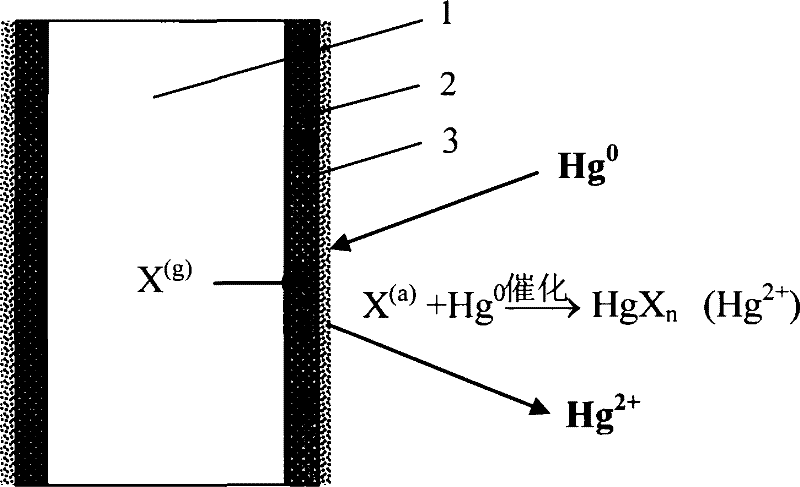

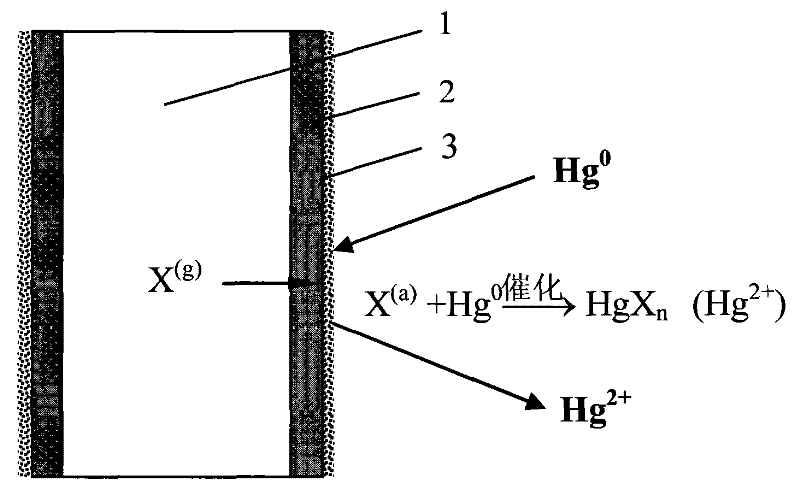

[0029] Use γ-Al with a micropore diameter of 100nm 2 o 3 The ceramic membrane tube is used as the main body of the membrane module, namely figure 1 For the ceramic membrane diffusion layer (2) shown, the outer diameter of the ceramic membrane tube is 15 mm, and the outer surface is planar; a layer is prepared on the outer surface of the ceramic membrane tube by solution impregnation method figure 1 As shown in the catalyst layer (3), the catalyst layer is made of manganese oxide, and the mass fraction of the manganese load is 1.2%; one such ceramic membrane tube is placed in a glass tube with an inner diameter of 20mm to make a single tube structure Membrane components; figure 1 The oxidizing agent (X (g) ) selects HCl, which is introduced from the top of the ceramic tube, diffused and released from the membrane inner cavity (1) to the outer catalyst layer (3), and is adsorbed and enriched on the outer catalyst layer (3) to form an adsorbed oxidant (X (a) ); the diffusion ...

Embodiment 2

[0034] Adopt the gamma-Al of loading 1.2% manganese oxide used in embodiment 1 2 o 3 The ceramic membrane tube is used as the main body of the membrane module, namely figure 1 Shown ceramic membrane diffusion layer (2), utilizes 5 this ceramic pipes to make tubular ceramic membrane module reactor; Oxidant (X (g) ) choose Cl 2 , Cl 2 It enters from the top of the ceramic tube, and diffuses and releases from the membrane cavity (1) through the ceramic membrane diffusion layer (2) to the catalyst layer (3), so that it is enriched on the catalyst layer on the outer surface of the membrane tube, and Cl 2 The diffusion flux through the ceramic membrane is 1.0mmol / (m 2 h), the Cl diffused into the flue gas 2 The concentration is 0.8ppm.

[0035] Into the reactor into the zero-valent mercury concentration of 126μg / m 3 , gas volume of 200L / h, mercury-containing flue gas at 250°C, other components in the flue gas SO 2 500ppm, NO 50ppm, N 2 80%, CO 2 11%, O 2 7% and 2% water v...

Embodiment 3

[0038] Use γ-Al with a micropore diameter of 200nm 2 o 3 The ceramic flat plate is used as the main body of the membrane module. The ceramic flat plate is 400mm long, 150mm wide, and 16mm thick; a layer of cobalt oxide with a loading of 1.5% is prepared on the outer surface of the ceramic membrane by solution impregnation method as the catalytic active material, and the mass of cobalt Doped with 1% molybdenum as a reference.

[0039] A plate-type ceramic membrane module reactor is made by using 4 pieces of the above-mentioned ceramic plate tubes, and the distance between the plates is 8mm; bromine chloride (BrCl) is selected as the oxidant, and BrCl is passed into the ceramic plate and diffused to the catalyst layer outside the plate. Release, so that It is enriched on the catalyst layer on the outer surface of the plate, Cl 2 The diffusion flux through the ceramic membrane is 1.0mmol / (m 2 h), the BrCl concentration diffused into the flue gas is 0.8ppm.

[0040] The concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com