Pretreatment method for improving cigarette adaptability of tobacco stems

An adaptive and pretreatment technology, applied in the treatment of tobacco, tobacco, application, etc., can solve problems such as no better solution, prolonging the production cycle of tobacco stems, and unsatisfactory effects of tobacco stems, so as to meet the needs of large-scale industrial The production and technical effects are remarkable, and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

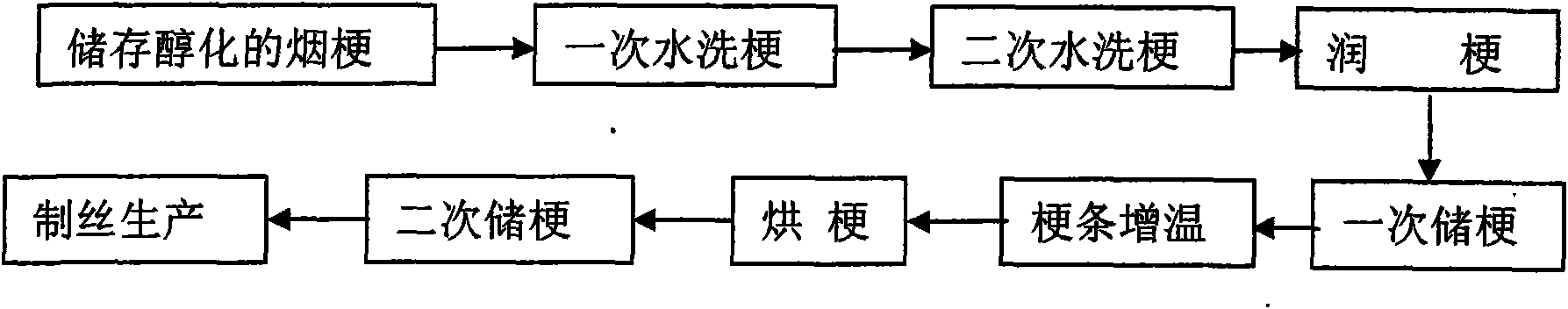

Image

Examples

Embodiment 1

[0025] The raw material is 2006 C4F tobacco stems. Based on the fact that the texture of "raw stems" is relatively tough, and due to long-term storage, there will be some dust and impurities on the surface. In order for the tobacco stems to better absorb water during the moistening process, it is necessary to First, the tobacco stems are washed with warm water once in a stem washing machine. While cleaning debris, the surface of the tobacco stems is properly humidified to soften the tobacco stems to a certain extent. During this process, the water temperature of the water-washing stem tank machine is controlled at 67-68°C, and the soaking and washing time of the tobacco stems is controlled at 10-12 seconds. The main purpose of the secondary washing of the stems is to partially remove the viscous colloidal substances on the surface of the "raw stems". Therefore, the tobacco stems rinsed with warm water are soaked at high temperature in a stem washing machine, and the tobacco ste...

Embodiment 2

[0028] 2007 Hongda C3F tobacco stems 1400kg. The original stem moisture content is 12.93%.

[0029] The specific process steps are: ① One-time washing stem: the material enters the washing stem machine through the conveyor belt for warm water washing. During this process, the water temperature is controlled at 61-62°C, and the passage time of the tobacco stem in the washing stem tank is 15-17 seconds; ②Secondary washing of stems: the tobacco stems rinsed with warm water are transported to soaking in a stem washing machine. The water temperature of the washing machine is controlled at 77-78°C, and the soaking time is controlled at 60-62 seconds; The finished tobacco stems are processed by the HT moistening machine, the temperature of the tobacco stem machine is controlled at 66-67°C, and the output moisture is controlled at 36-37%; ④Primary storage: transport the moistened tobacco stems to the storage cabinet It is stored for 5 hours from fully entering the cabinet to coming o...

Embodiment 3

[0032] 2008 NC102 BSF Stems 1400kg. The raw stem water was 11.98% BSF.

[0033] The specific process steps are: ① One-time washing stem: the material enters the washing stem machine through the conveyor belt for warm water washing. During this process, the water temperature is controlled at 64-65°C, and the passage time of the tobacco stem in the washing stem tank is 18-20 seconds; ②Secondary washing stems: the tobacco stems rinsed with warm water are transported to the stem washing machine for soaking. The water temperature of the stem washing machine is controlled at 80-81°C, and the soaking time is controlled at 62-64 seconds; The finished tobacco stems are processed by the HT moistening machine, the temperature of the tobacco stem machine is controlled at 65-66°C, and the output moisture is controlled at 37-38%; ④Primary storage: transport the moistened tobacco stems to the storage cabinet It is stored for a total of 3 hours from fully entering the cabinet to coming out o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com