Light shield, hole arrangement and method for reducing dishing of metal plug

A metal plug, metal plug technology, applied in the field of hole layout for providing metal plugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

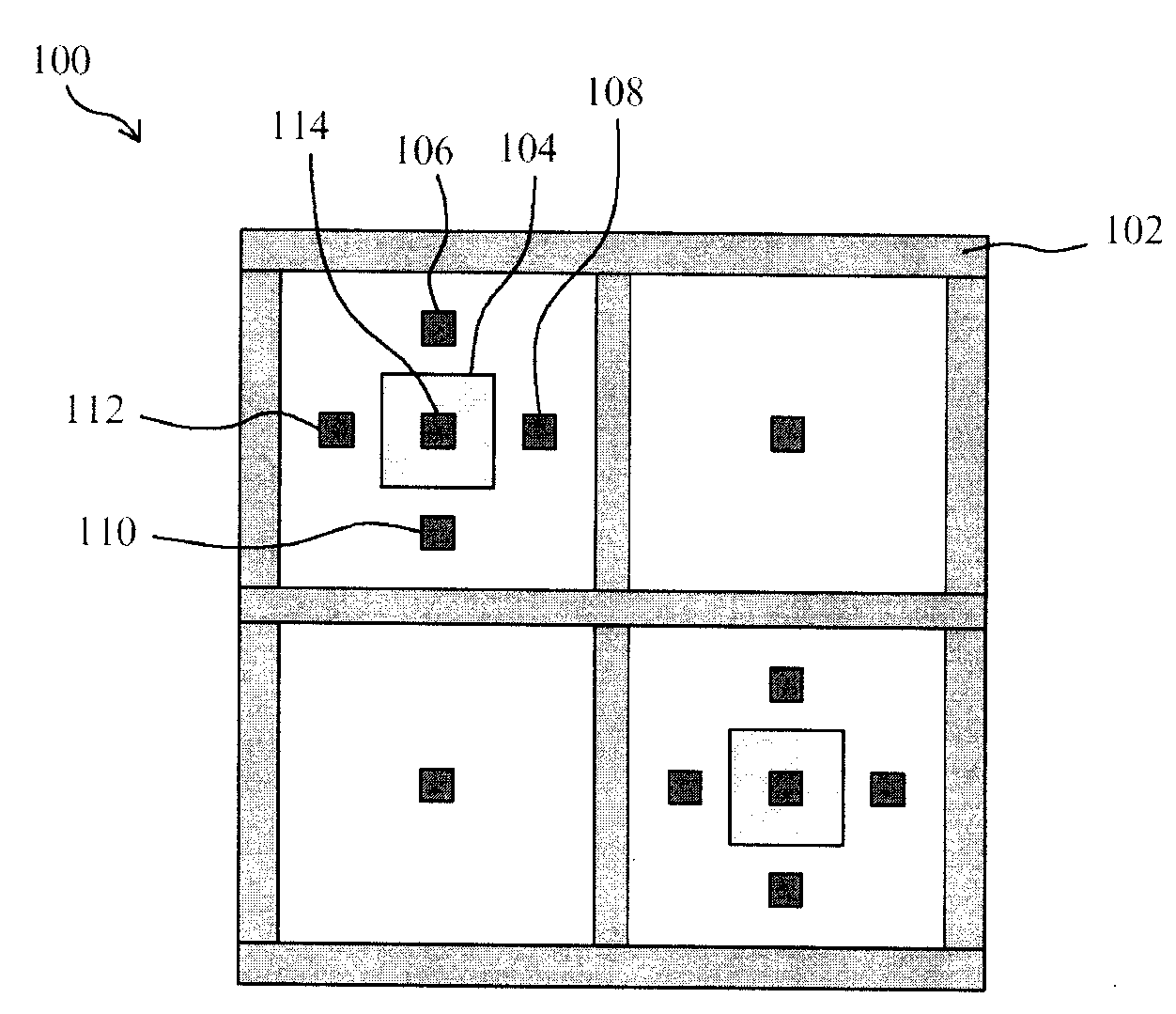

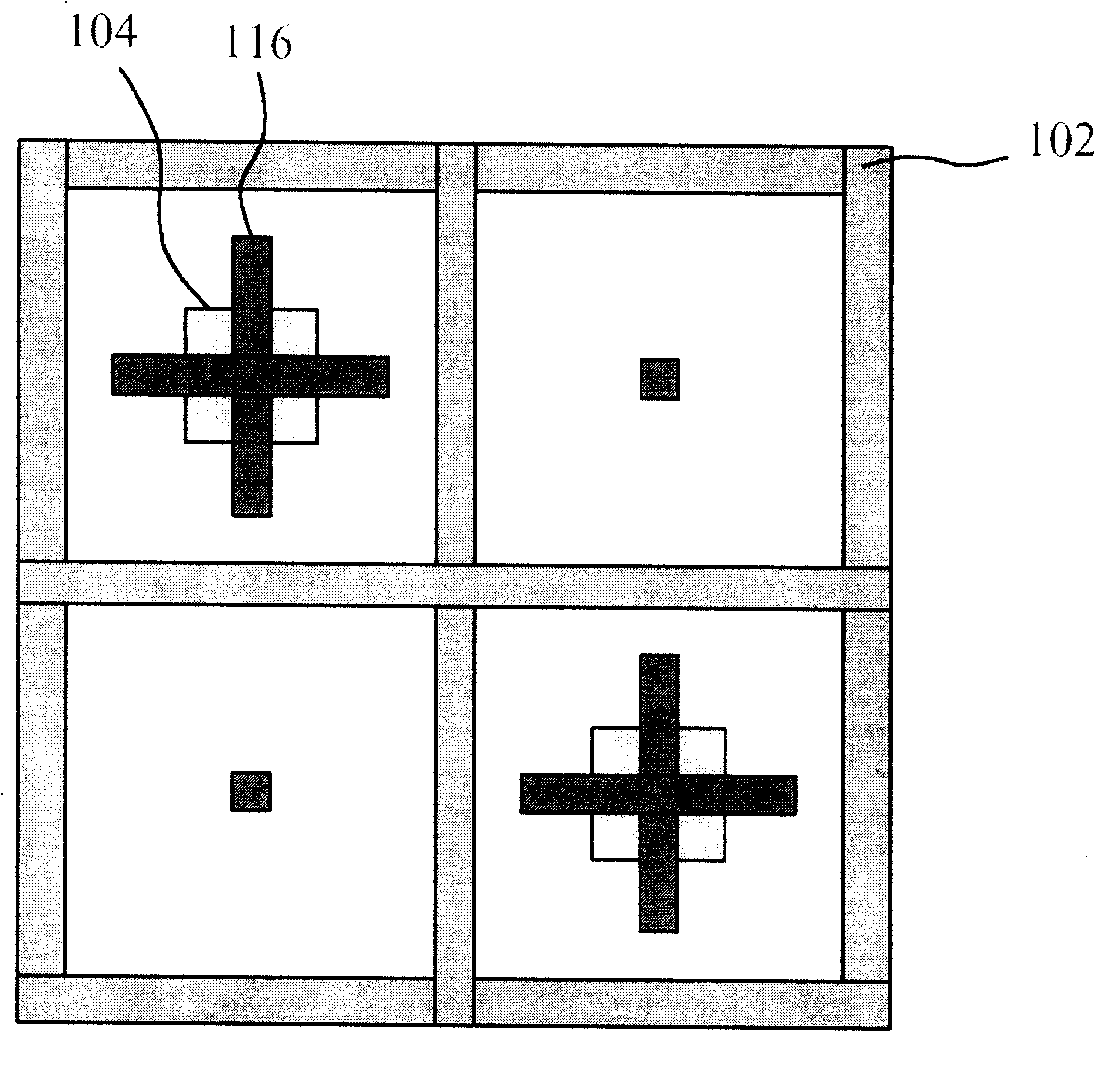

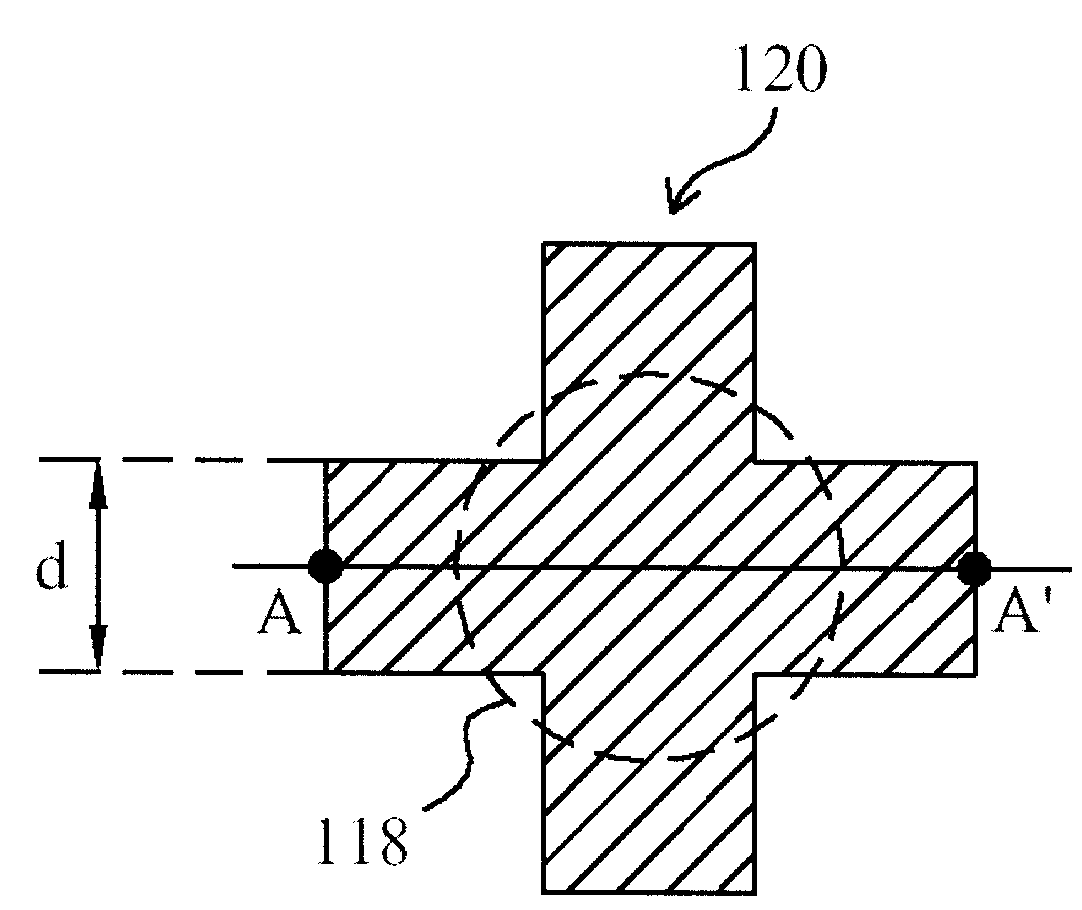

[0068] see now Figure 3A and Figure 3B , Figure 3A and Figure 3B yes figure 2 Schematic illustration of the dishing phenomenon caused by the hole layout shown. As shown in the figure, the dishing portion 134 of the tungsten plug 132 is close to the cross portion 118 in the hole 120 , which is the critical portion of the hole 120 .

[0069] see again Figure 4 , Figure 4 is a schematic diagram according to the first embodiment of the present invention. As shown, the reticle 210 includes a hole pattern 220 fabricated on a substrate, the hole pattern 220 having a shape defined by a closed boundary and a reduced critical portion 222 within the boundary, the critical portion The minimum dimension d2 of 222 is intentionally reduced to be smaller than the dimension d1 of the original layout design. The optical lithography process 230 is performed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com