Heat sink built in cavity cylindrical light emitting diode wick

A technology of light-emitting diodes and cooling devices, applied in the field of light sources, can solve the problems of not being able to take away heat, affecting the service life of wicks, and easy burning of light-emitting diodes, so as to achieve the effect of improving heat dissipation efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

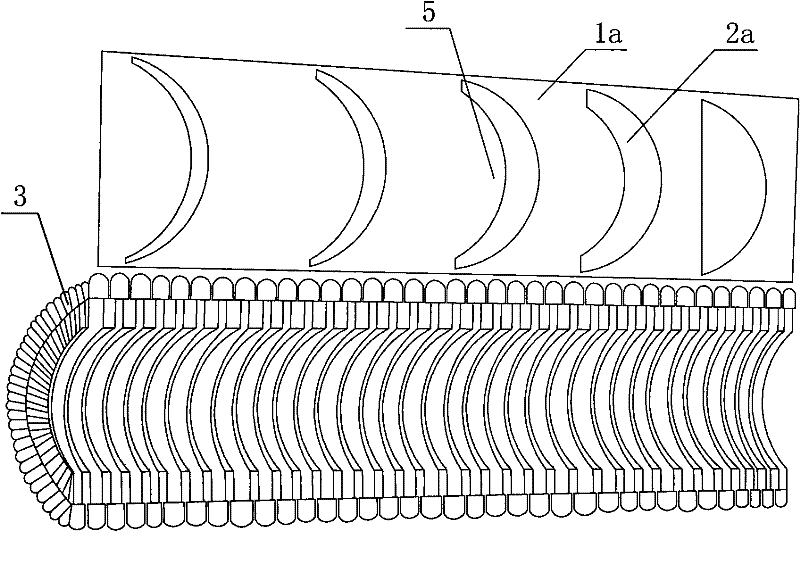

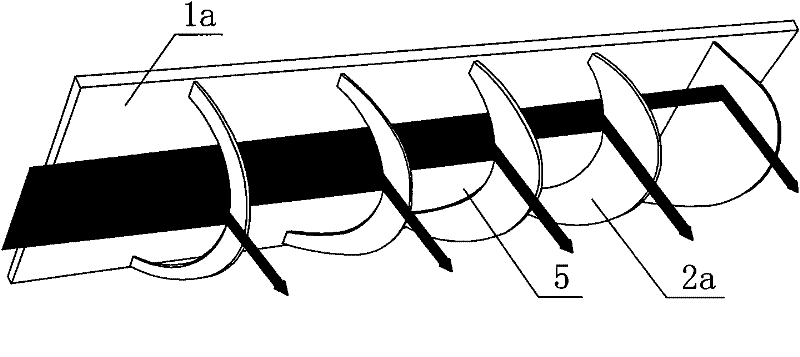

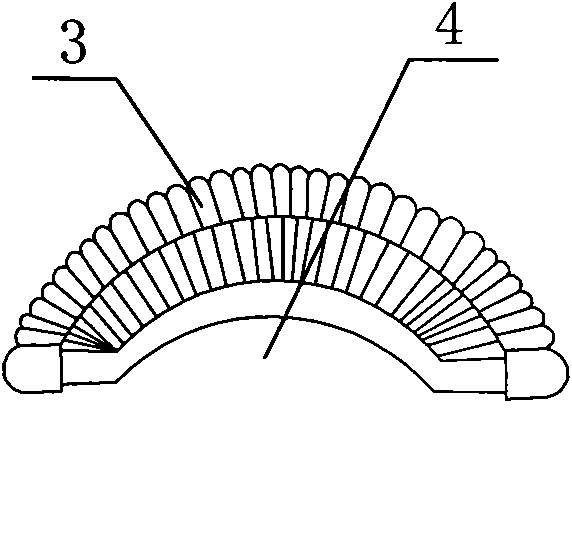

[0028] The light-emitting diode wick 3 of this embodiment is semi-cylindrical, and the fixture and blade structure placed in its chamber 4 are as follows: figure 1 , figure 2 As shown, the fixing part is a bakelite fixing plate 1a of suitable specifications, on which five reflective arc-shaped blades 2a are arranged, and the arc-shaped blades 2a are sequentially For the first, second, third, fourth and fifth blades, the area of the opening 5 at the root of the first blade is the largest, and the area of the blade is the smallest, followed by the second, and so on, and the end blade has no opening , into a completely closed shape, when a beam of uniform heat dissipation medium with a certain pressure passes through the first blade, part of the heat dissipation medium is reflected by the blade to dissipate heat for the LED corresponding to the section of the wick, and the rest of the heat dissipation medium is from the The lower part of the first blade passes through, and ...

Embodiment 2

[0031] According to the same principle, LED wicks of various shapes can also be manufactured. Such as Figure 7 The light-emitting diode wick 3 shown is in the shape of a quadrangular prism, and the corresponding fixing part is a shelf 1b with an X-shaped cross-section. Each unit chamber 4 of the X-shaped shelf 1b is respectively provided with the plurality of reflective blades 2b . The X-shaped frame 1b is built in the quadrangular prism light-emitting diode wick 3, then constitutes Figure 9 The quadrangular prism LED wick shown, from Figure 8 It can be seen that when a heat dissipation medium that is uniform and has a certain pressure enters the quadrangular prism light-emitting diode wick 3, the heat dissipation medium is divided into four equal parts, and when each part of the medium passes through the blades of each zone, it is divided into four equal parts. The set number of reflective mediums for each blade can give the light emitting diodes of each segment surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com