Drawing frame shaft housing

A drawing frame and shaft sleeve technology, which is applied to bearing components, coiling mechanisms, shafts and bearings, etc., can solve the problems of aggravating bearing wear, shortening the life of the shaft sleeve, deformation and bending of the mandrel, and prolonging the service life. Long life and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

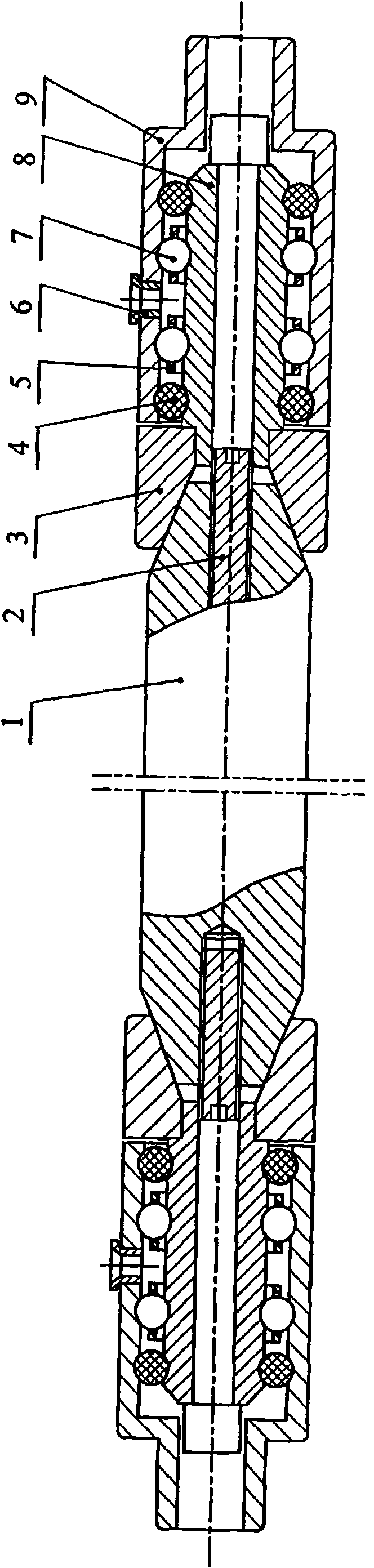

[0009] Below in conjunction with accompanying drawing, the present invention is specifically introduced as follows:

[0010] Such as figure 1 As shown, the biscuit maker shaft sleeve of the present invention includes a mandrel 1 installed on the textile machine. The two ends of the mandrel 1 are arranged in a symmetrical short conical structure, and a screw hole is pre-processed at the top. The conical connector 3 Through the finishing process, it forms a fully closed combination with the short conical part at the end of the mandrel 1 . The inner ring 8 is hollow, and a thread is provided in the hollow part, and is integrally connected with the mandrel through the connecting bolt 2 . There is an extension section on the inner ring to form a stepped surface, which is closely matched with the conical connector 3, so that the mandrel 1, the conical connector 3, the inner ring 8 and the connecting bolt 2 form a relative rotation with the outer ring body.

[0011] There is a dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com