Calendar on-line thickness-measuring device

A technology for calendering and thickness measurement, which is applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effects of automation and integration, reduction of environmental pollution, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

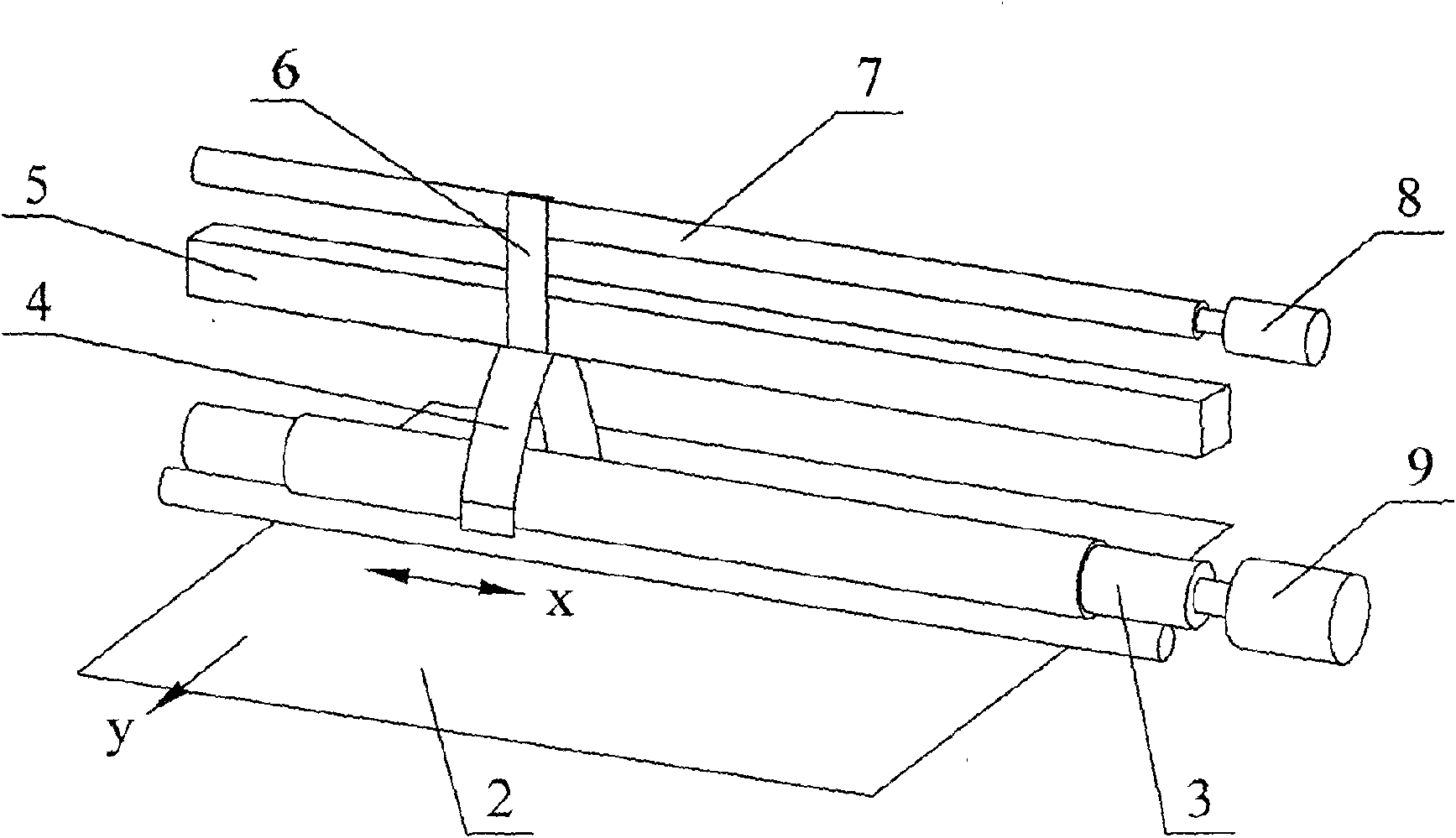

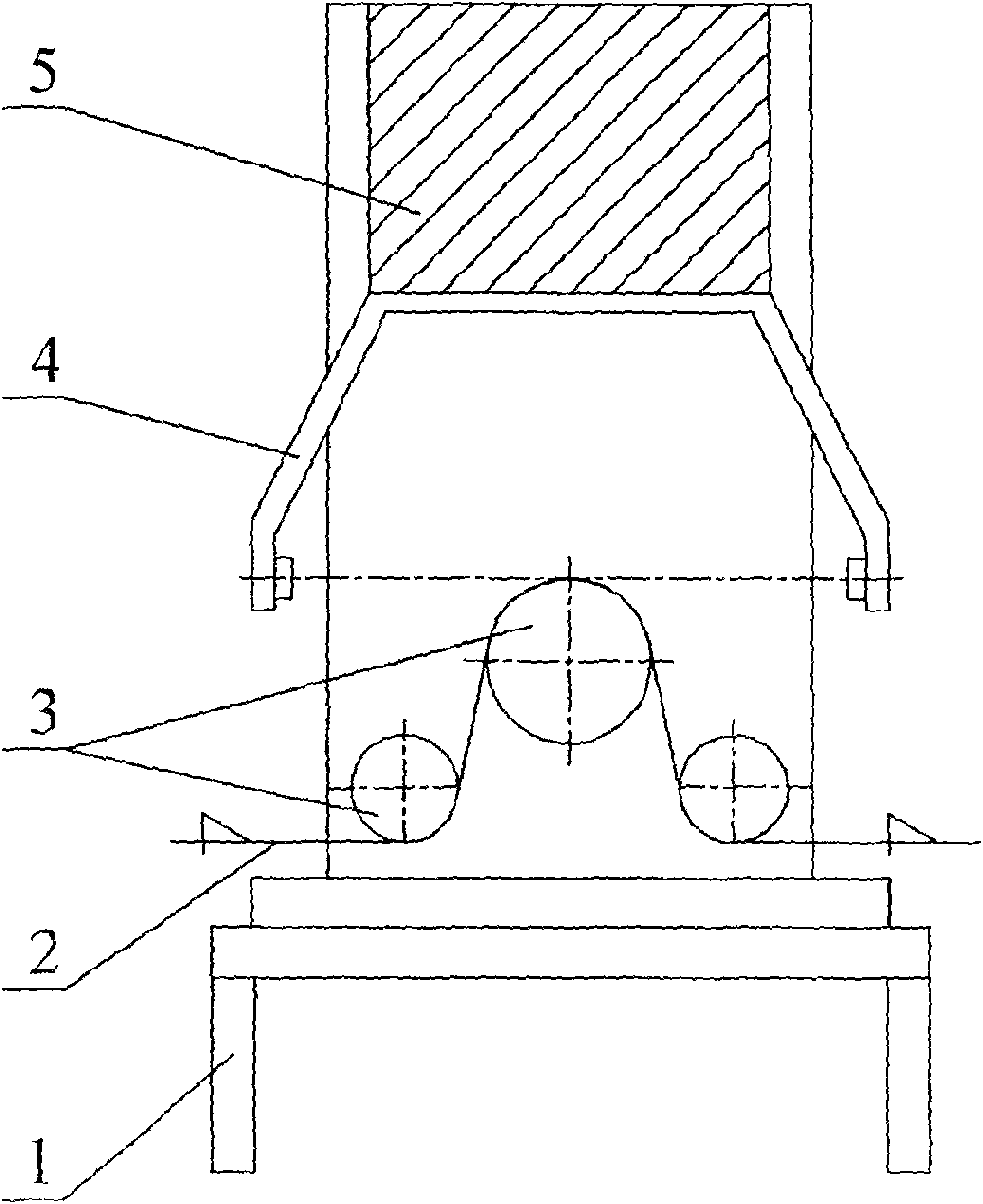

[0012] Below in conjunction with embodiment and attached figure 1 , attached figure 2 The present invention is described further:

[0013] This embodiment is an online calender thickness measurement device that applies virtual instrument technology, field bus technology, and single-chip microcomputer technology to the online thickness measurement system for calender products. 0.5mm; width 1~5.5M. The production speed of the calender is 100-200M / min; the moving load of this embodiment is below 10kg.

[0014] The device of this embodiment is composed of a support 1, a measured rolled product 2, a guide roller 3, a sensor device 4, a guide rail 5, a slider 6, a ball screw 7, a servo motor 8 and a frequency conversion motor 9. The sensor Device 4 is the core component of this embodiment, which includes an optical system, a CCD sensor, a measurement and control system, a sensor data acquisition module, a two-dimensional coordinate acquisition module, a data communication module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com