Honeycomb ceramic dry green body dual-blade cutting machine

A technology of honeycomb ceramics and cutting machines, which is applied in the direction of ceramic forming machines, stone processing tools, working accessories, etc., can solve the problems such as patents of honeycomb ceramic cutting machines, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

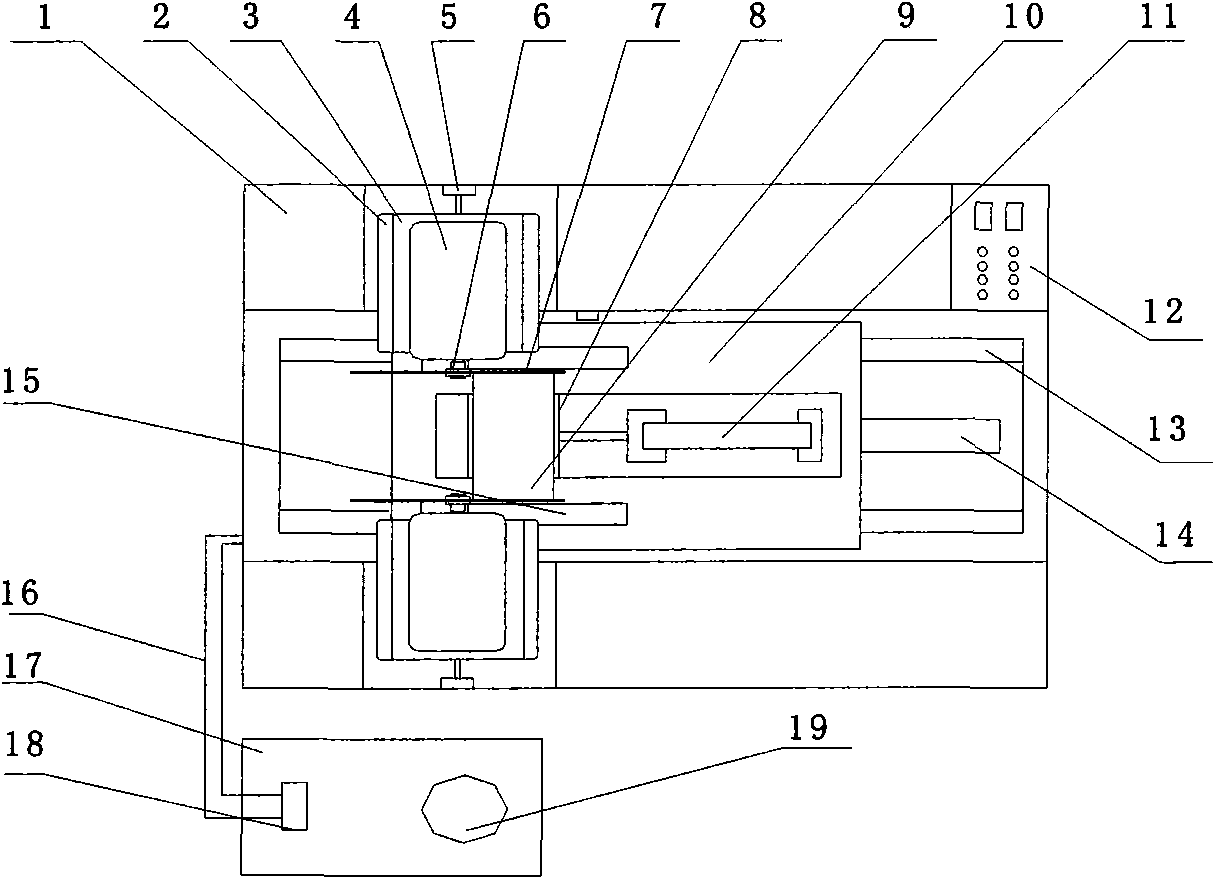

[0026] Embodiment: according to the honeycomb ceramic dry body double-knife cutting machine prototype that makes according to the above-mentioned embodiment, its main parameter is:

[0027] 1. Dimensions: 1400mm×1200mm×1400mm

[0028] 2. Total machine weight: 600kg

[0029] 3. Total motor power: 3.5KW

[0030] 4. Maximum stroke of linear platform: 500mm

[0031] 5. Linear platform speed: 0.75~1000mm / min

[0032] 6. Linear platform movement linearity: 0.02mm / 500mm

[0033] 7. Linear platform size: 600×400mm

[0034] 8. Maximum thickness of cutting material: 50mm~260mm

[0035] 8. Round blade specification: Φ 外径 400~600mm, Φ 内径 32mm, blade thickness 3~4mm

[0036] 9. Adjustable distance between two blades: 50mm~400mm

[0037] 10. Cutting body precision: ±0.05mm

[0038] 11. Frequency conversion motor speed: 0~2840r / min

[0039] 13. The rotation accuracy of the cutter shaft is ≤0.01mm

[0040] 14. Output: 120-200 pieces / h

[0041] 15. The noise and dust produced by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com