Ignition transformer for a discharge lamp

A technology for transformers and discharge lamps, applied in electric light sources, electrical components, lighting devices, etc., can solve the problems of ignition transformer loss, converter loss, etc., and achieve the effect of less electromagnetic interference and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

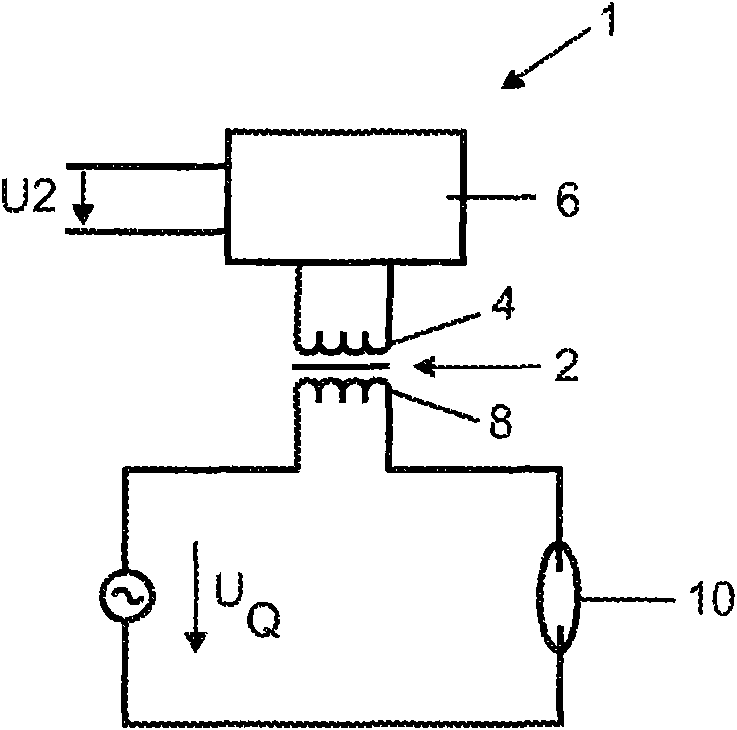

[0029] exist figure 1 A circuit arrangement 1 according to the invention with an ignition transformer 2 is shown in .

[0030] Primary winding 4 of ignition transformer 2 is fed with pulse source 6 and ignition voltage U2 . The primary winding 8 of the ignition transformer 2 is connected in series with the discharge lamp 10 and passes the driving voltage U Q to feed. Preference is given to using high-pressure gas discharge lamps, for example mercury-containing metal-halide vapor lamps of the type "OSRAM HQI", as discharge lamps.

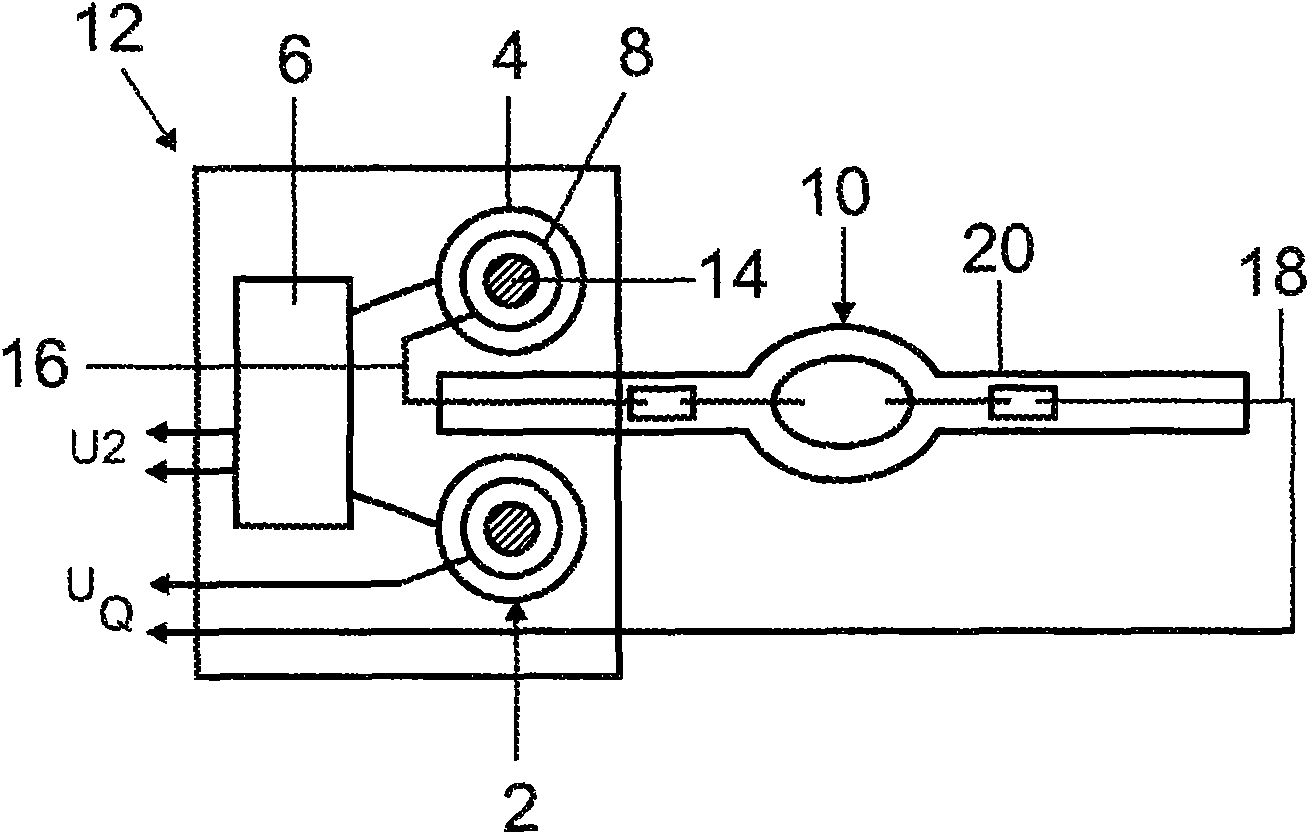

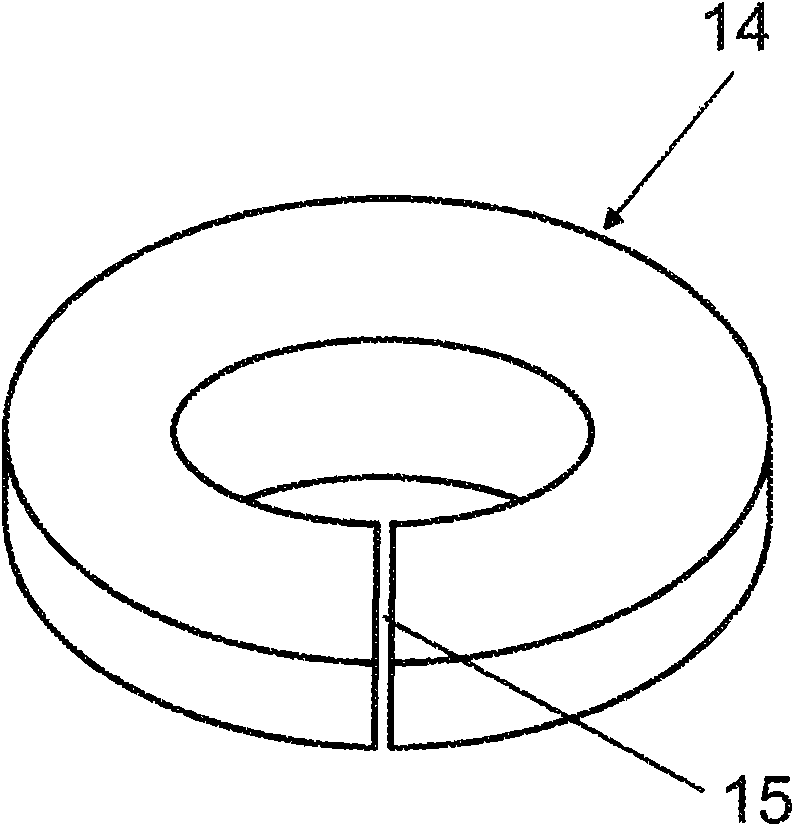

[0031] exist figure 2 The discharge lamp 10 in a base 12 is shown in . The burner 12 has a pulse source 6 via which the primary winding 4 of the ignition transformer 2 is fed. Ignite transformer 2 as figure 2 Shown in is preferably ring-shaped and has a transformer core 14, such as image 3 is shown with an air gap 15 . A secondary winding 8 is mounted on the transformer core 14 , which is surrounded by the primary winding 4 .

[0032] if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com