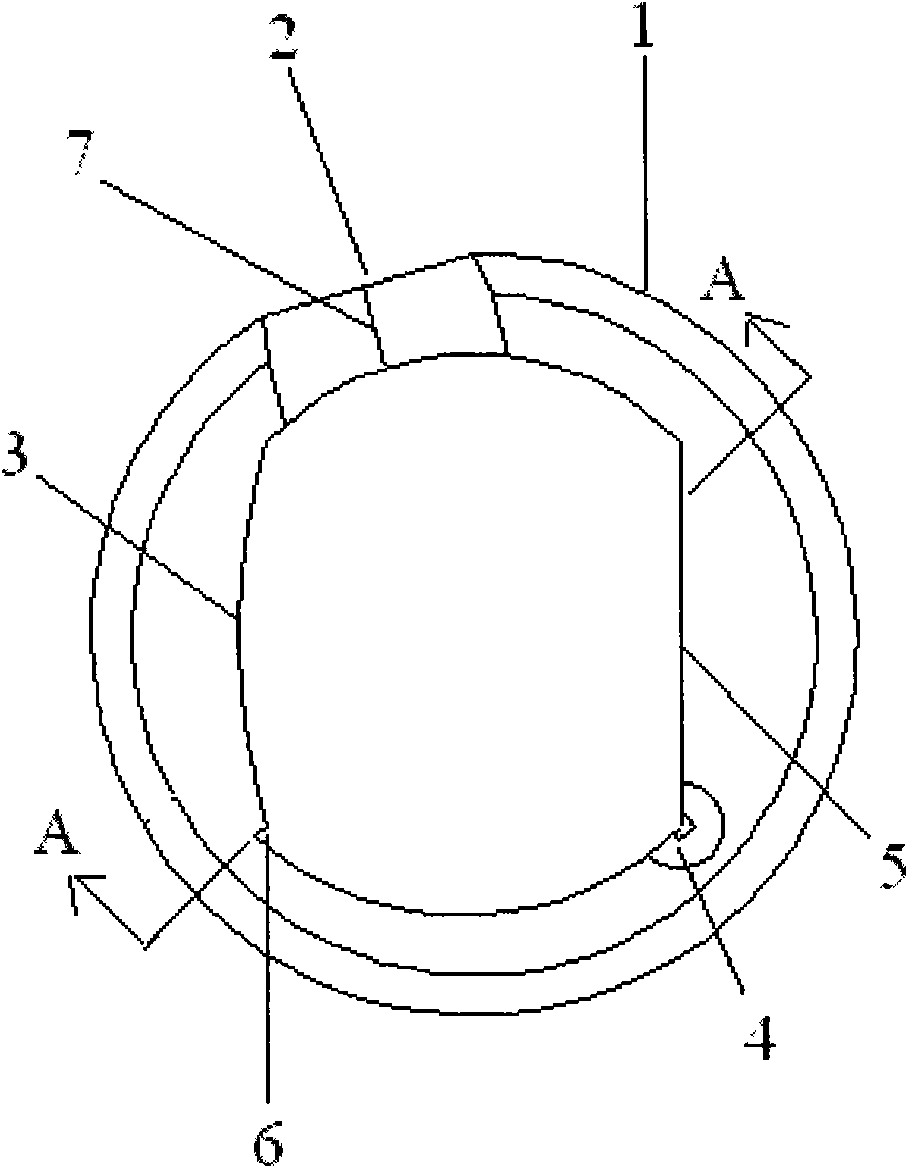

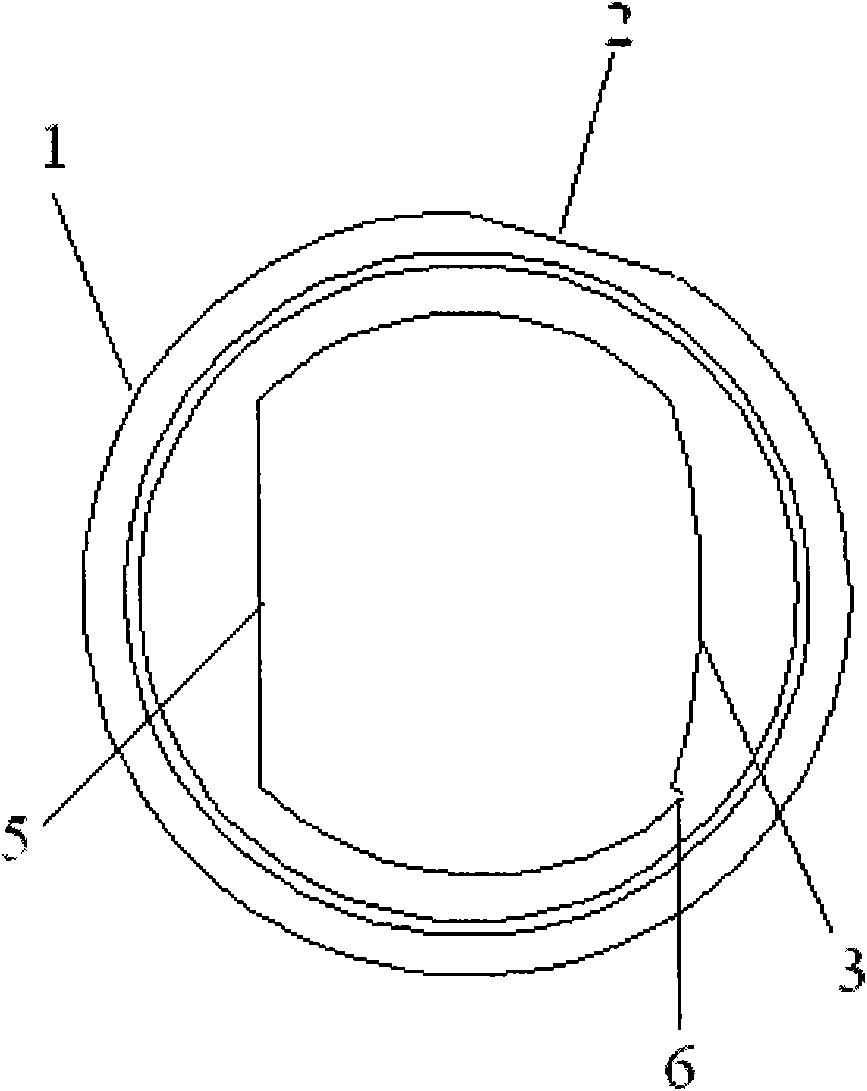

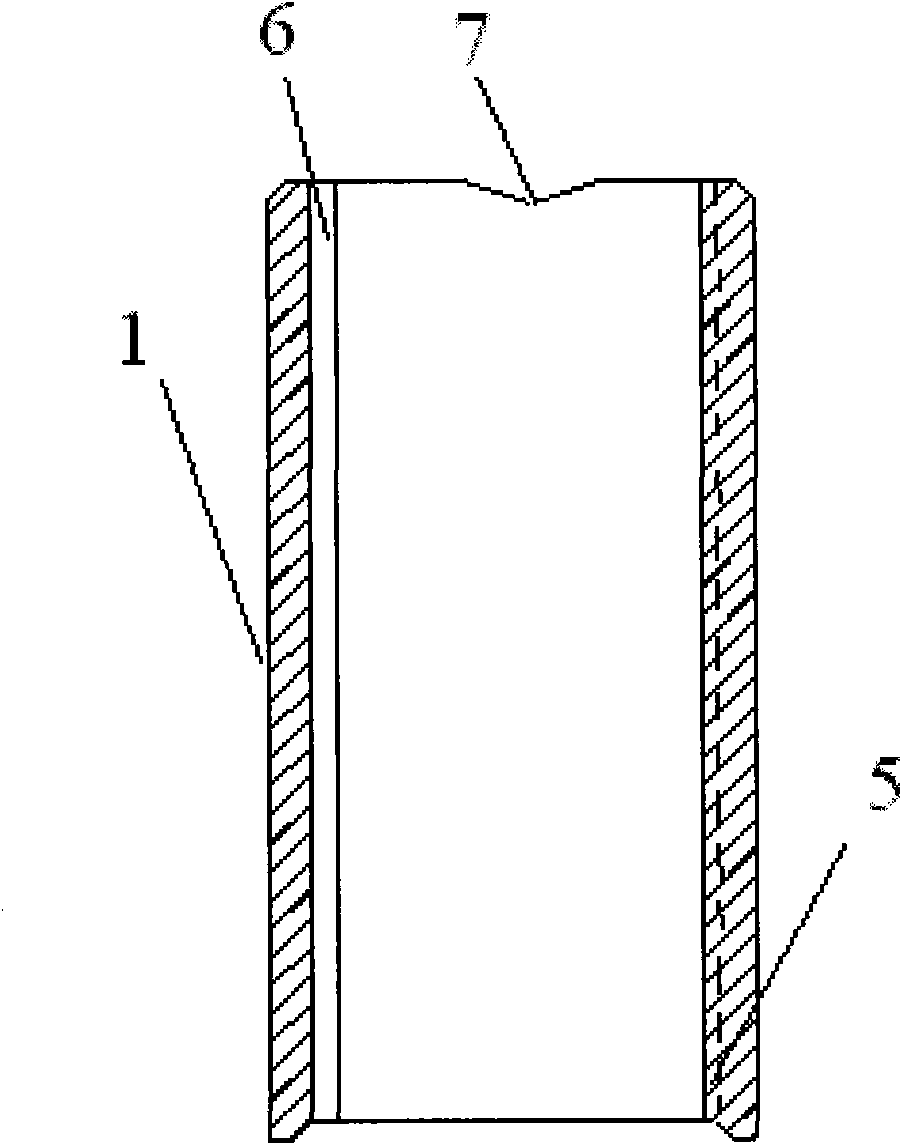

Powder metallurgy compressor unloading shaft sleeve and method for preparing same

A powder metallurgy and compressor technology, applied in the field of powder metallurgy compressor unloading bushing and its preparation, achieves the effects of high yield, few steps and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] After mixing Fe powder, C powder and Mo powder evenly, put them into a molding machine for molding; the parts by weight of each component are: C: 0.30, Mo: 1.0, and the rest is Fe powder; the temperature is controlled at 850°C, and pre-sintered ; followed by shaping; temperature control at 1050°C, and then sintering; heat treatment, after 8 hours, cryogenic treatment; vacuum oil immersion and telecentric separation in sequence, that is, the powder metallurgy compressor unloading sleeve is prepared.

[0030] After testing, the average hardness of the shaft sleeve is HRC≥38, the minimum hardness value is HRC≥35, and the residual austenite structure of the shaft sleeve is 15%, which fully meets the requirements for use. After the durability test, they all meet the life test requirements of the product.

Embodiment 2

[0032] After mixing Cu powder, Fe powder, C powder and Mo powder evenly, put them into a molding machine for molding; the parts by weight of each component are: Cu: 3.0, C: 1.0, Mo: 2.0, and the rest is Fe powder; Control temperature at 940°C, pre-sintering; then shaping; temperature control at 1100°C, then sintering; heat treatment, 6 hours later, cryogenic treatment; vacuum oil immersion and telecentric separation in sequence to prepare powder metallurgy compressor unloading shaft set.

[0033] After testing, the average hardness of the shaft sleeve is HRC ≥ 38, the minimum hardness value is HRC ≥ 35, and the residual austenite structure of the shaft sleeve is 10%, which fully meets the requirements for use. After the durability test, they all meet the life test requirements of the product.

Embodiment 3

[0035] After mixing Cu powder, Fe powder, C powder and Mo powder evenly, put them into a molding machine for molding; the parts by weight of each component are: Cu: 1.0, C: 0.50, Mo: 1.5, and the rest is Fe powder; Control the temperature at 890°C, pre-sintering; then carry out shaping; control the temperature at 1120°C, and then sinter; conduct heat treatment, and after 2 hours, carry out cryogenic treatment; carry out vacuum oil immersion and telecentric separation in sequence, that is, the powder metallurgy compressor unloading shaft is prepared set.

[0036] After testing, the average hardness of the shaft sleeve is HRC ≥ 38, the minimum hardness value is HRC ≥ 35, and the residual austenite structure of the shaft sleeve is 5%, which fully meets the requirements for use. After the durability test, they all meet the life test requirements of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com