System for producing stepped modularized acrylic filaments

A production system and a stepped technology, applied in the field of acrylic filament production, can solve the problems such as the inability to meet unlimited mass production of acrylic filament, the large equipment and equipment of acrylic filament production, easy pilling and deformation of spinning, etc. Realize the effect of low-cost quantitative production, small footprint and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical solution of the above invention in more detail, the following inventors listed specific examples to illustrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

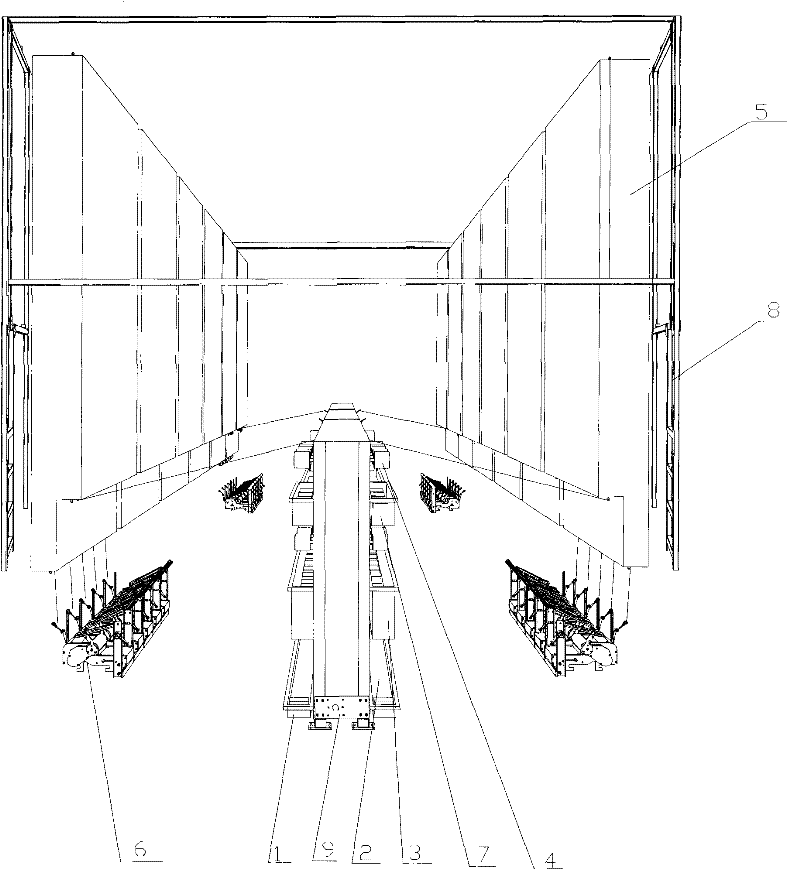

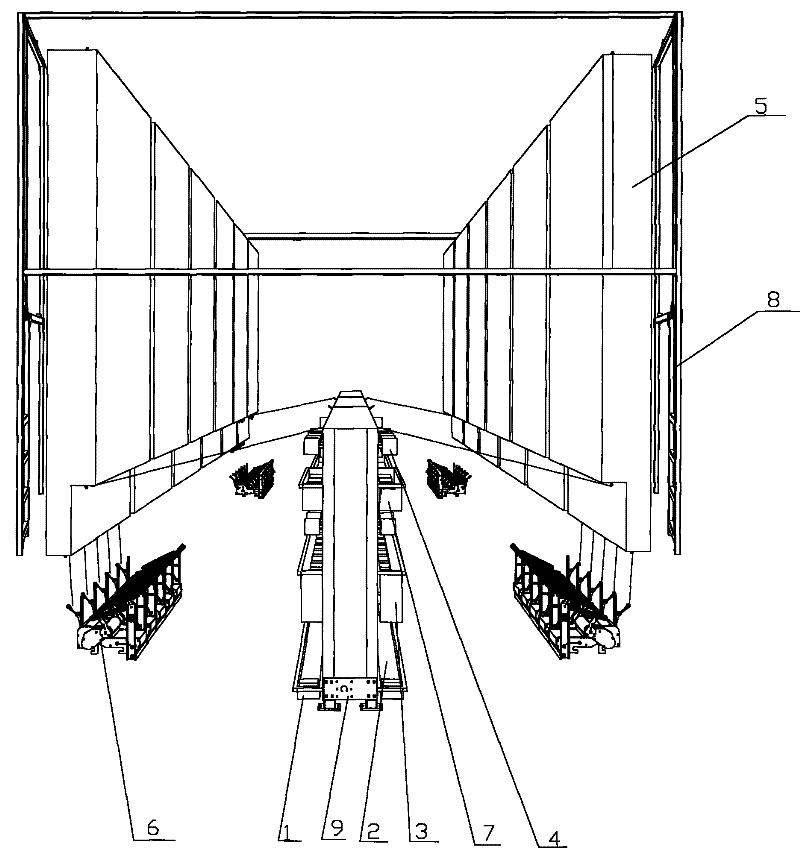

[0029] Example figure 1 , the stepped modular acrylic filament production system is a wet spinning process system, including a production line controlled by a control system, the production line includes a power unit 9 and the power unit drives and connects 5 to 20 acrylic fiber lengths A silk production module, the acrylic filament production module at least includes a sequentially arranged rotary spinning box 1, a solvent drafting machine 2, a washing machine 3, a thermal drafting device 4, a jacketed biphenyl heat pipe densification drying device 5 and Parallel fiber winder6. Wherein the spinning box, solvent drawing machine, water washing machine, and hot drawi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com