Automatic time control and pressure regulation scald apparatus

A time-adjusting and pressure-adjusting technology, applied in the direction of heating surgical instruments, etc., can solve the problems of changes in the pressure contact surface of the metal scalding head, uneven depth, affecting the research results, etc., to achieve accurate scalding time, steam pressure and temperature control, and shape. Consistent with size and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

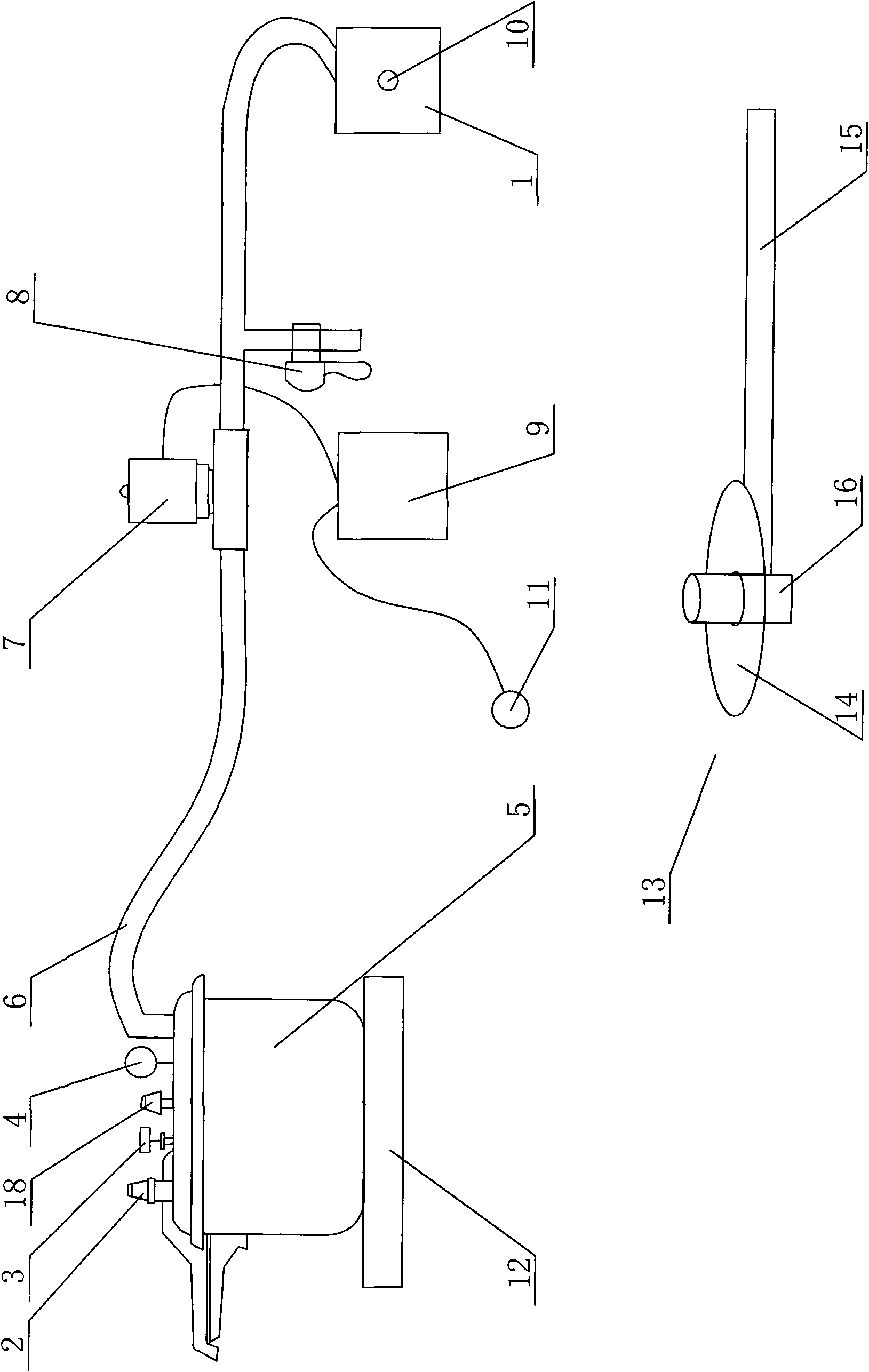

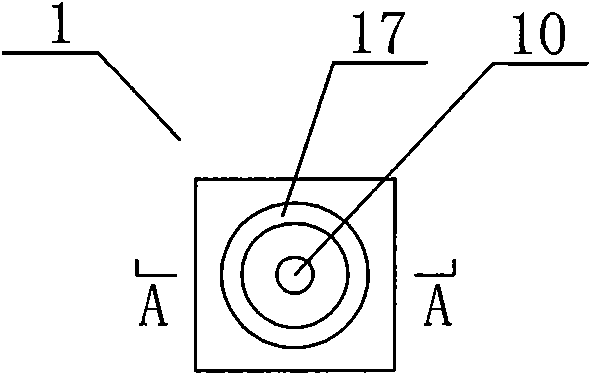

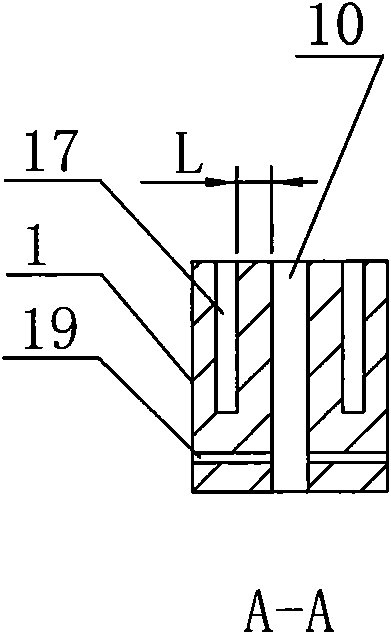

[0022] figure 1 In the illustrated embodiment, the automatic time-controlled and pressure-regulated scald instrument of the present invention includes an induction cooker 12, a pressure cooker 5, a steam nozzle 1, a steam delivery pipe 6, a solenoid valve 7, a steam and water discharge valve 8, and a scald mold 13. Manually adjustable steam pressure valve 2, digital display thermometer 3 and pressure gauge 4 and original safety valve 18 are installed on the pressure cooker 5. The steam spray head is made of foam, and the center of the foam has a steam hole 10 that runs through the foam, and its diameter is smaller than the inner diameter of the steam delivery pipe 6; an annular groove 17 is formed on the periphery of the steam hole 10, and its The depth is less than the depth of the steam hole 10, and its caliber is greater than the caliber of the steam hole. The distance between the inner wall of the steam hole and the inner wall of the annular groove is 0.3~0.5cm. There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com