Solid laser with optical fiber pump arrangement

A technology of solid-state lasers and optical fiber pumps, applied in lasers, laser components, phonon exciters, etc., can solve problems such as temperature difference, refractive index difference, and laser operating mode influence

Inactive Publication Date: 2010-11-10

NORTH CHINA ELECTRIC POWER UNIV (BAODING)

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The use of end-pumped solid-state lasers, including the use of lenses to couple pump light, is a technology well known in the art, and the pump light source used is a laser diode or other suitable pump sources; the solid gain medium is based on the required laser. Different dielectric materials are selected for different wavelengths. Crystals such as the well-known YAG are often used by those skilled in the art. The shape of the gain medium is generally round or rectangular. A cooling system is installed around the gain medium. Including water cooling and air cooling, and other suitable cooling devices, but this traditional pumping method and gain medium form is prone to a problem, that is, due to uneven pumping and cooling between the inner and outer layers of the gain medium The inhomogeneity of the laser will produce a temperature difference, and the temperature difference in the gain medium will cause many problems, such as causing damage to the gain medium itself, inhibiting the increase of the laser output power, especially because the temperature difference will also produce a refractive index difference inside the gain medium, Thus affecting the laser operation mode

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

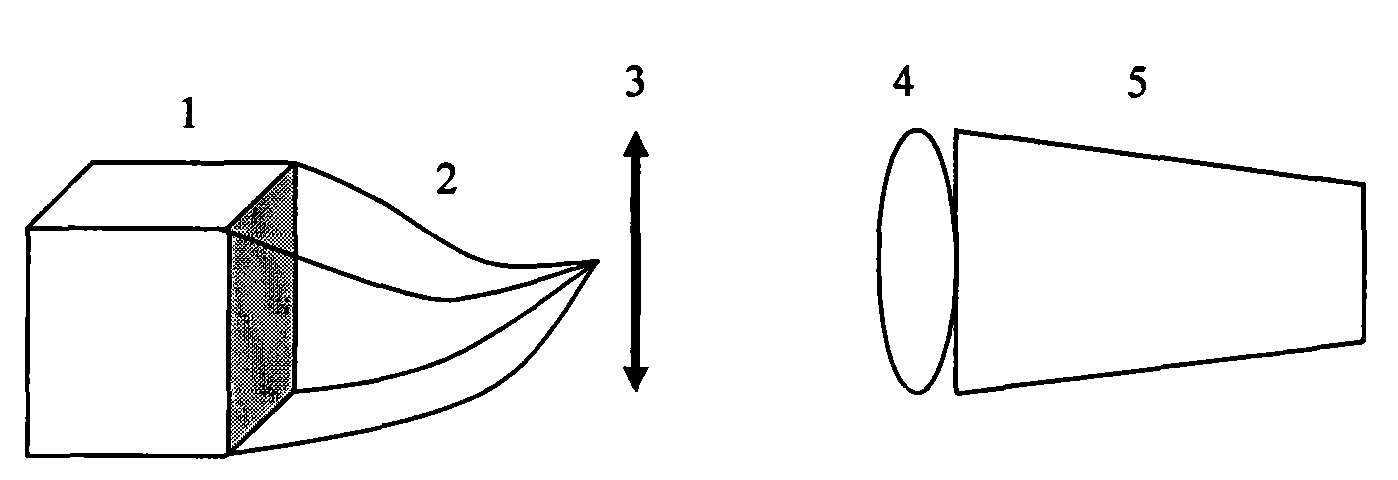

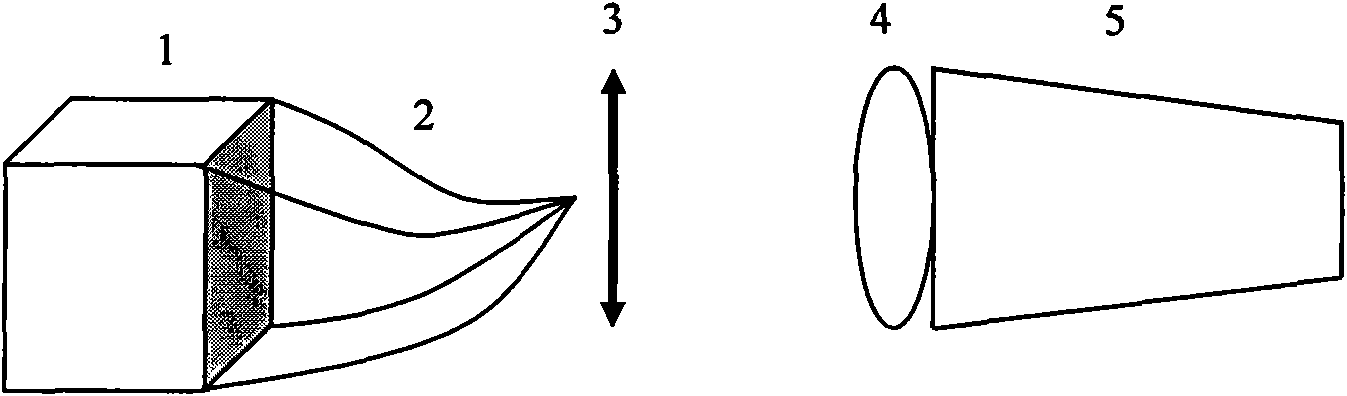

The invention discloses a solid laser with an optical fiber pump arrangement. The solid laser comprises a plurality of laser diodes, a circular convex lens and a truncated cone-shaped gain medium. Theplurality of laser diodes are arranged in a plane, the circular convex lens is positioned between the truncated cone-shaped gain medium and the plane of the plurality of laser diodes, wherein, an output terminal of each of the plurality of laser diodes is connected with an optical fiber, and the other end of the optical fibers is bunched. One end of the bunch is provided with a convergent lens. The convergent lens is positioned between the circular convex lens and the end of the bunch. The distance between the convergent lens and the circular convex lens is longer than sum of focal distance of the convergent lens and the focal distance of the circular convex lens. The focal distance of the circular convex lens is longer than length of the truncated cone-shaped gain medium. A larger section of the truncated cone-shaped gain medium is on one side of the circular convex lens and parallel to the circular convex lens and the convergent lens. Diameter of the larger section equals to the diameter of the circular convex lens, and the truncated cone-shaped gain medium and the circular convex lens are arranged in contact with each other.

Description

Solid-state laser with fiber-pumped device technical field The invention relates to an optical fiber pumping device, in particular to a solid-state laser using the pumping device, wherein the gain medium is in the shape of a truncated cone. Background technique The use of end-pumped solid-state lasers, including the use of lenses to couple pump light, is a technology well known in the art, and the pump light source used is a laser diode or other suitable pump sources; the solid gain medium is based on the required laser. Different dielectric materials are selected for different wavelengths. Crystals such as the well-known YAG are often used by those skilled in the art. The shape of the gain medium is generally round or rectangular. A cooling system is installed around the gain medium. Including water cooling and air cooling, and other suitable cooling devices, but this traditional pumping method and gain medium form is prone to a problem, that is, due to uneven pumping and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01S3/16H01S3/06H01S3/08H01S3/0941

Inventor 任芝李松涛姜根山

Owner NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com