Intelligent steam reclaiming machine set

A steam and unit technology, applied in steam generation, mechanical equipment, machines/engines, etc., can solve problems such as many intermediate links, poor stability, waste of water resources, etc., to reduce intermediate driving links, improve performance, and enhance radial effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

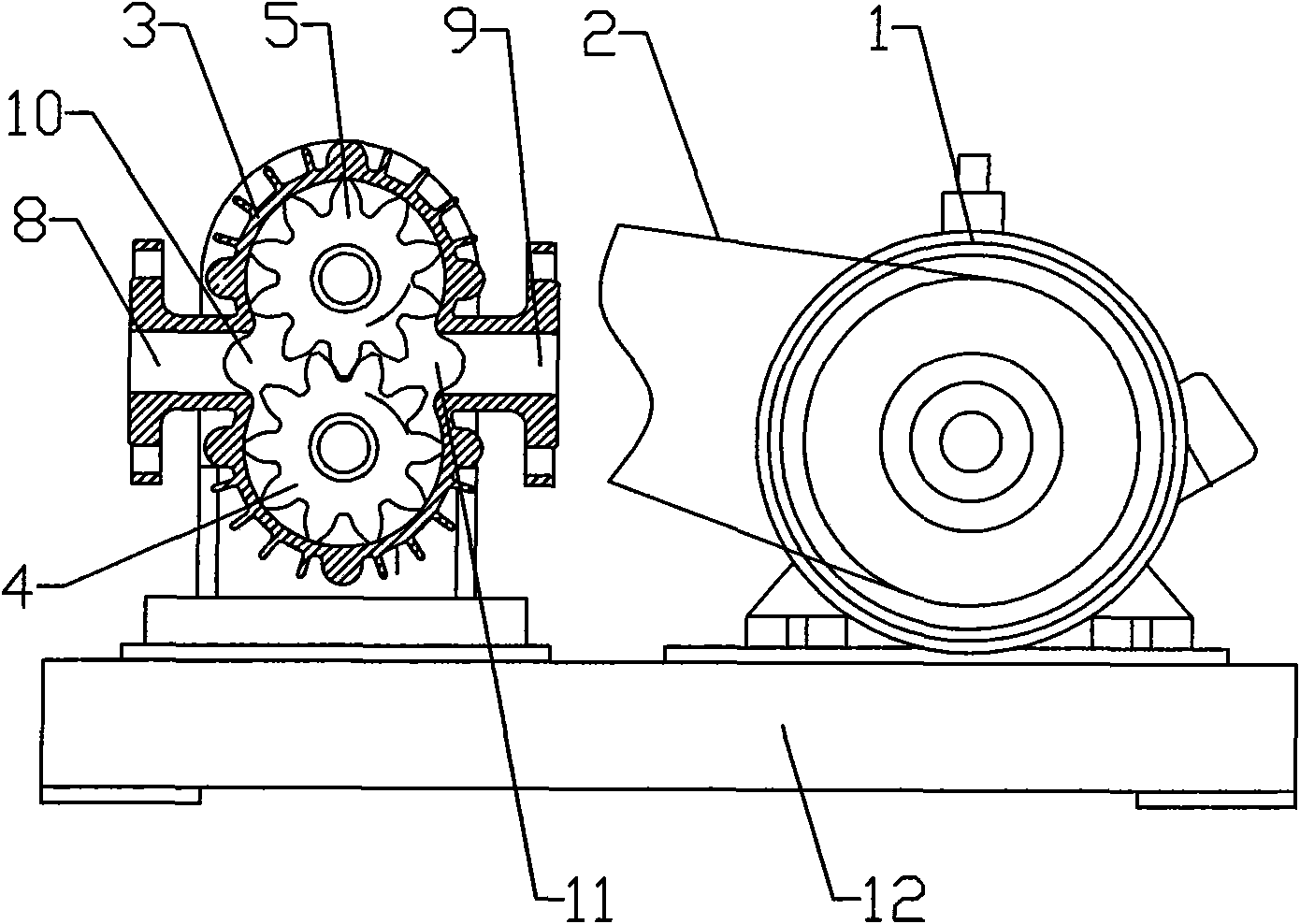

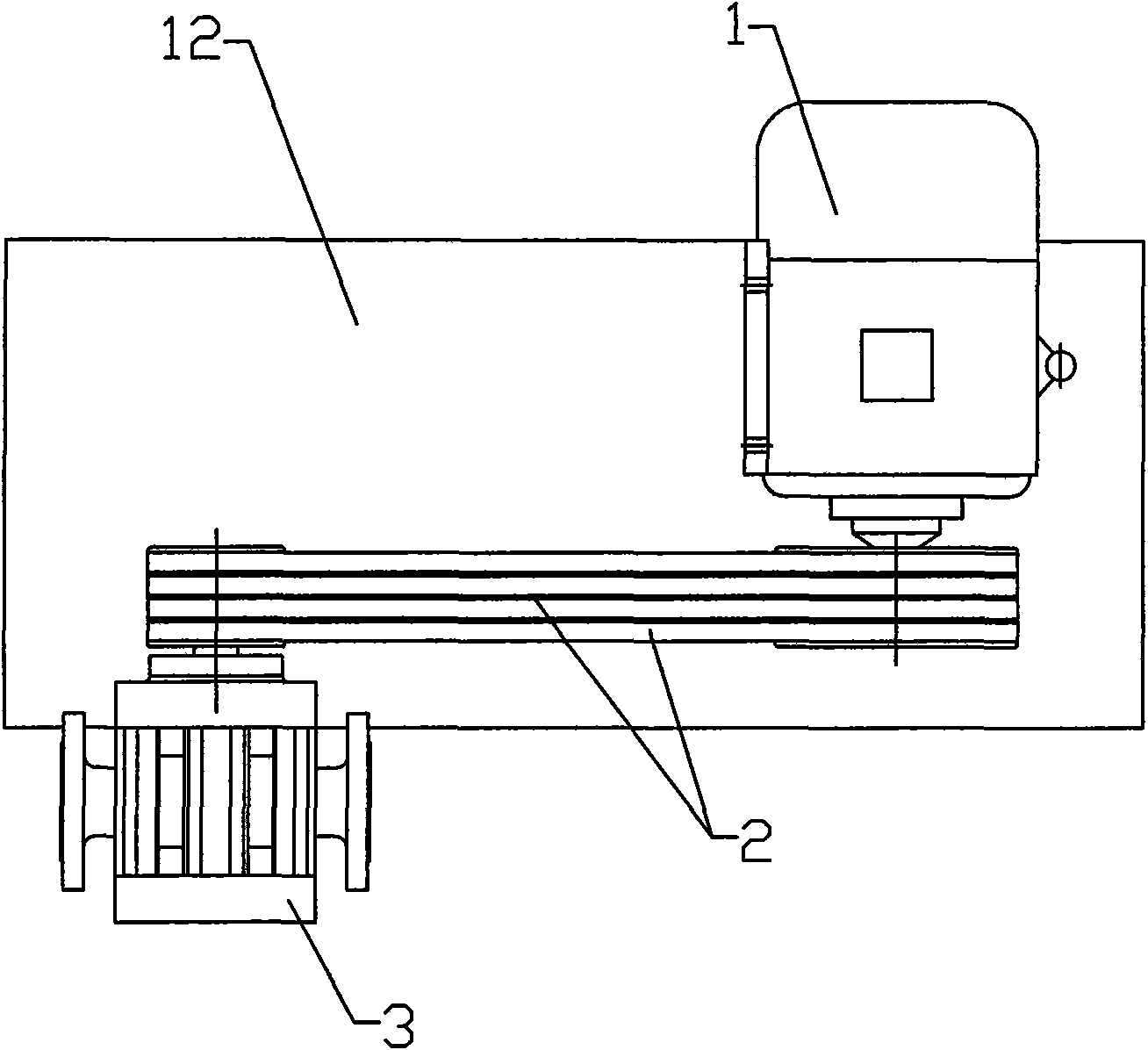

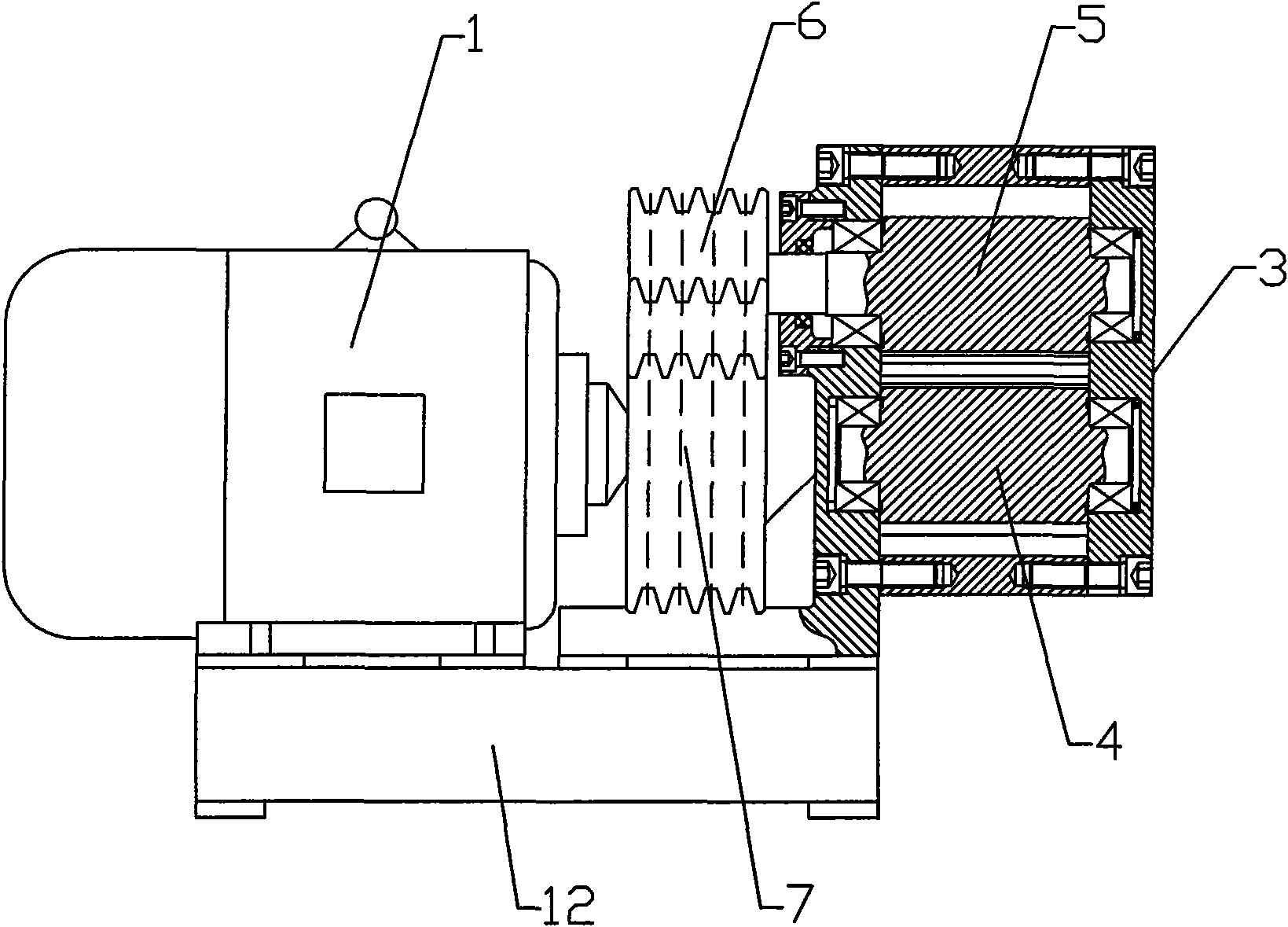

[0017] Examples such as figure 1 , figure 2 As shown, an intelligent steam recovery unit includes a machine head installed on the machine base 12 and a power drive device connected to the machine head transmission. The power drive device includes a motor 1 installed on the machine base 12, and the machine head It includes a gear pump housing 3 with a steam inlet 8 and a steam outlet 9, and a driving gear 5 and a driven gear 4 meshing with each other are installed in the gear pump housing 3, and the meshing parts of the driving gear 5 and the driven gear 4 are in contact with A front cavity 10 and a rear cavity 11 are respectively formed between the gear pump housings 3, the front cavity 10 is located in the gear pump housing 3 near the steam inlet 8, and the rear cavity 11 is located in the gear pump housing 3 The position close to the steam outlet 9, such as image 3 As shown, the driving gear 5 and the driven gear 4 are arranged up and down, and the driven pulley 6 coaxia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com