ACE inhibitory peptide in fermented milk and preparation method thereof

A technology of fermented milk and inhibitory peptides, which is applied in the field of enzyme inhibitory peptides and its preparation, can solve the problems of high production conditions, expensive equipment, complex production processes, etc., and achieve low production conditions, high food safety, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

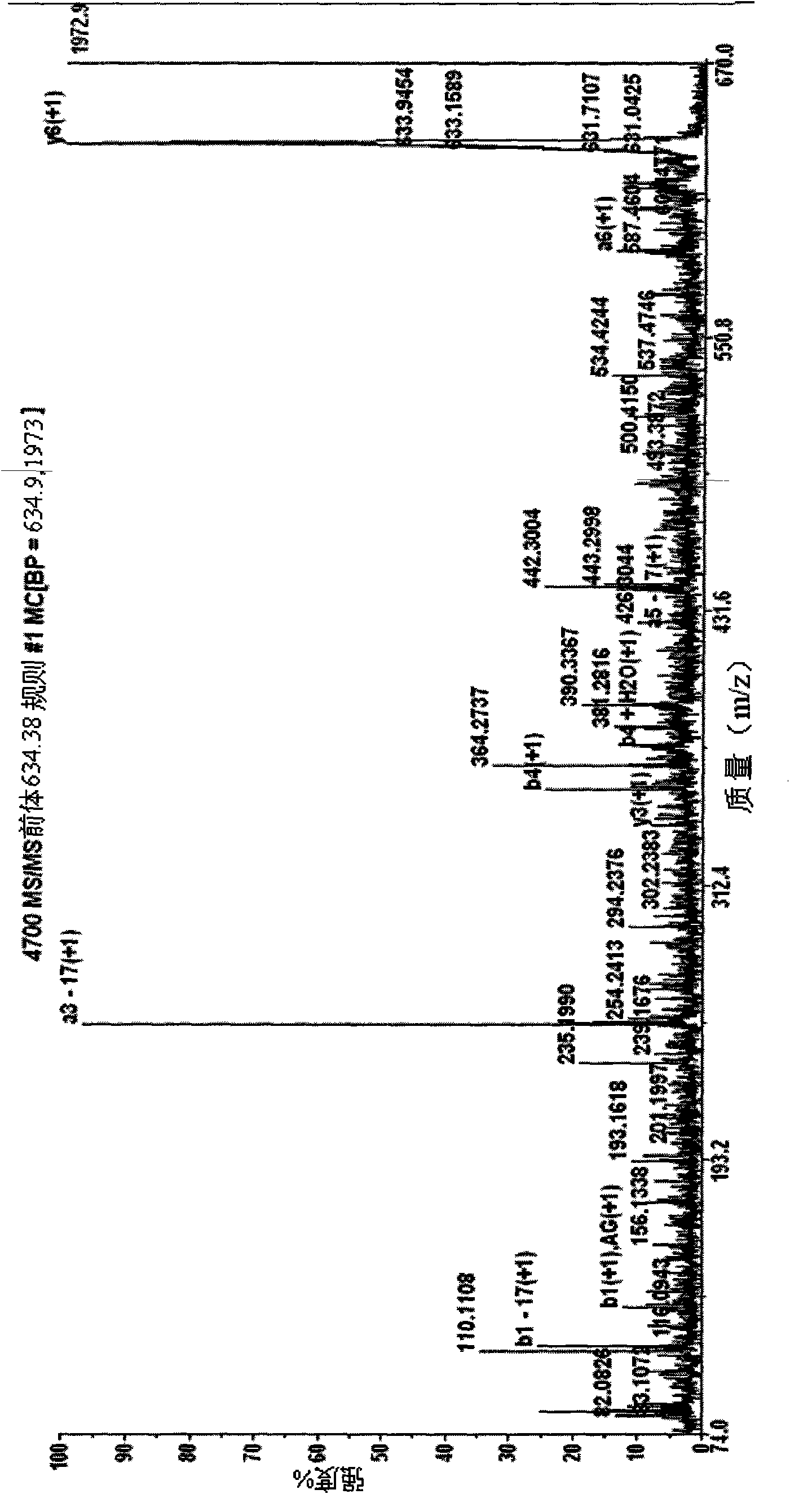

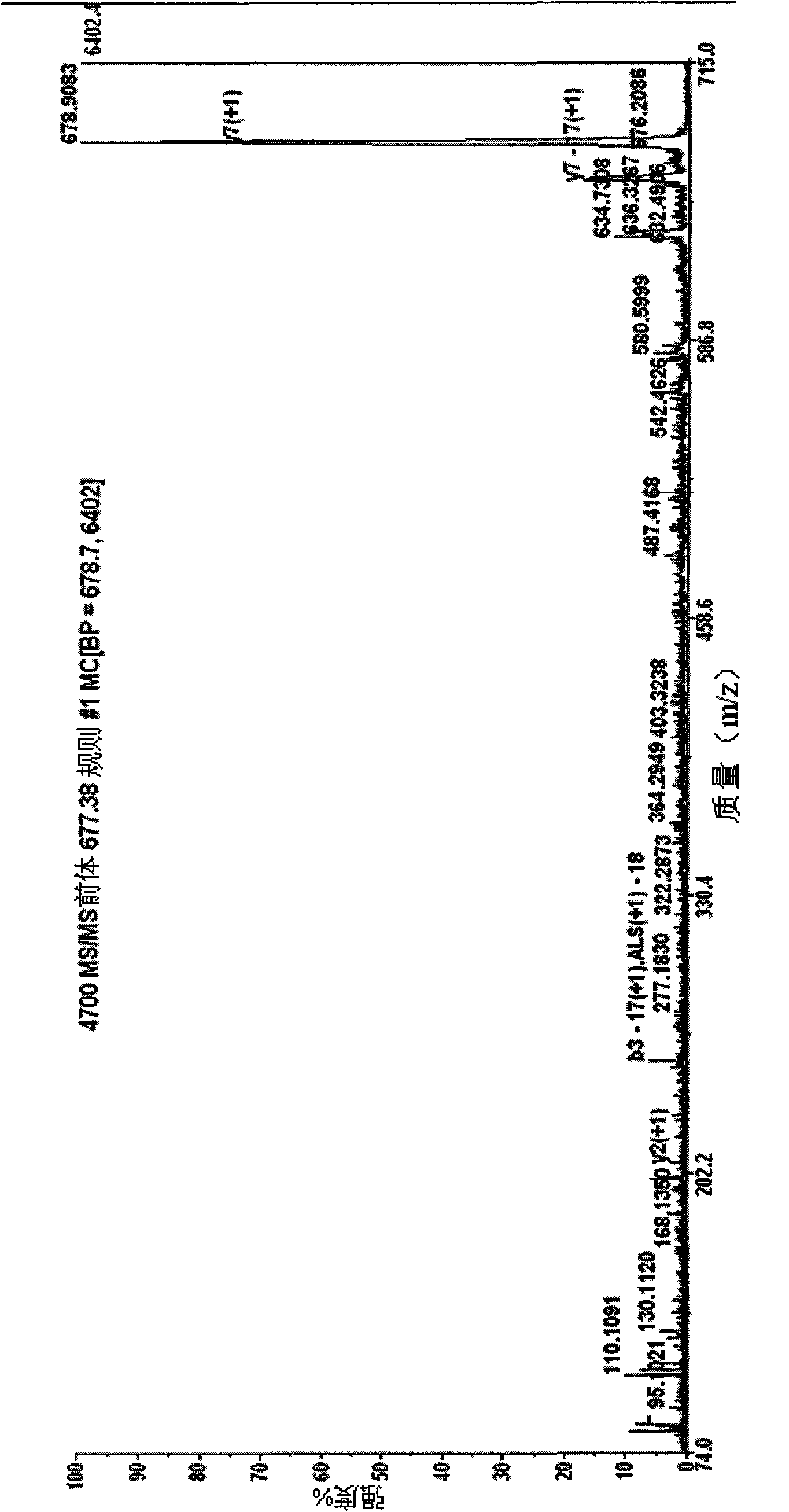

[0013] Specific embodiment 1: The ACE inhibitory peptide in fermented milk in this embodiment is mainly composed of four small molecular peptides whose amino acid sequences are KPAGDF, KAALSGM, KKAAMAM and LDHVPGGAR.

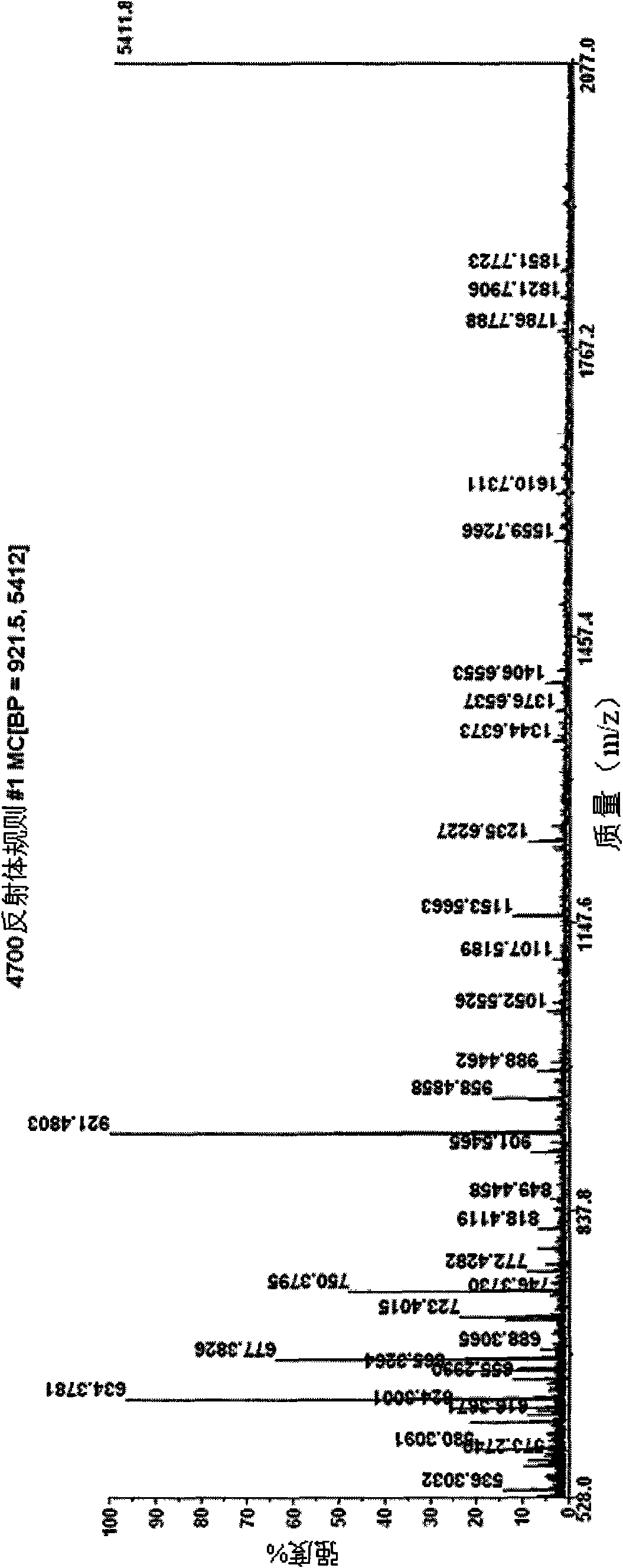

[0014] The ACE inhibitory peptide in the fermented milk of this embodiment can be prepared by the method of the present invention; the ACE inhibitory peptide in the fermented milk of this embodiment also includes a small amount of other small molecular polypeptides (such as figure 1 Shown), its dry matter content <10%.

[0015] The ACE-inhibiting peptide in the fermented milk of the present embodiment can also be directly divided into 30%~40%: 30%~40%: 10%~20%: 10 % to 20% by mass, including unavoidable impurity polypeptides.

[0016] The dry matter content of the ACE-inhibiting peptide in the dried fermented milk of this embodiment is >90%, the salt content is between 0% and 1.6%, and there is no bitter taste.

specific Embodiment approach 2

[0017] Specific embodiment two: the ACE inhibitory peptide in the fermented milk of this embodiment is prepared according to the following steps: 1. Lactobacillus helveticus (Lactobacillus helveticus) L03-1 and Lactobacillus casei (Lactobacillus casei) SL5 are inoculated in a protein concentration of 11%~ 12% skim milk, and then fermented at 35 to 39°C for 36 to 72 hours to obtain fermented milk; 2. Centrifuge the fermented milk for 30 minutes at a speed of 4000r / min, take the supernatant and filter, and the filtrate is Inactivate the enzyme at ±1°C for 10-15 minutes, then centrifuge again at 4000r / min for 30 minutes, then filter the supernatant with an ultrafiltration membrane to obtain the permeate; 3. Freeze-dry the permeate to obtain ACE-inhibiting peptides in fermented milk; wherein, the inoculum size of Lactobacillus helveticus L03-1 in step 1 is 4×10 8 ~8×10 8 cfu / L, the inoculation amount of Lactobacillus casei SL5 was 4×10 8 ~8×10 8 cfu / L; the ultrafiltration membr...

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 2 is: in step 4, the freeze-drying controls the moisture content to <5%. Other steps and parameters are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com