Deep ultraviolet projection lithographic objective

A projection light and deep ultraviolet technology, applied in the direction of microlithography exposure equipment, optics, optical components, etc., can solve the problems of difficulty in making ultra-fine masks, small optical reduction magnification, and high price, so as to simplify the production of objective lenses and reduce The effect of production cost and difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

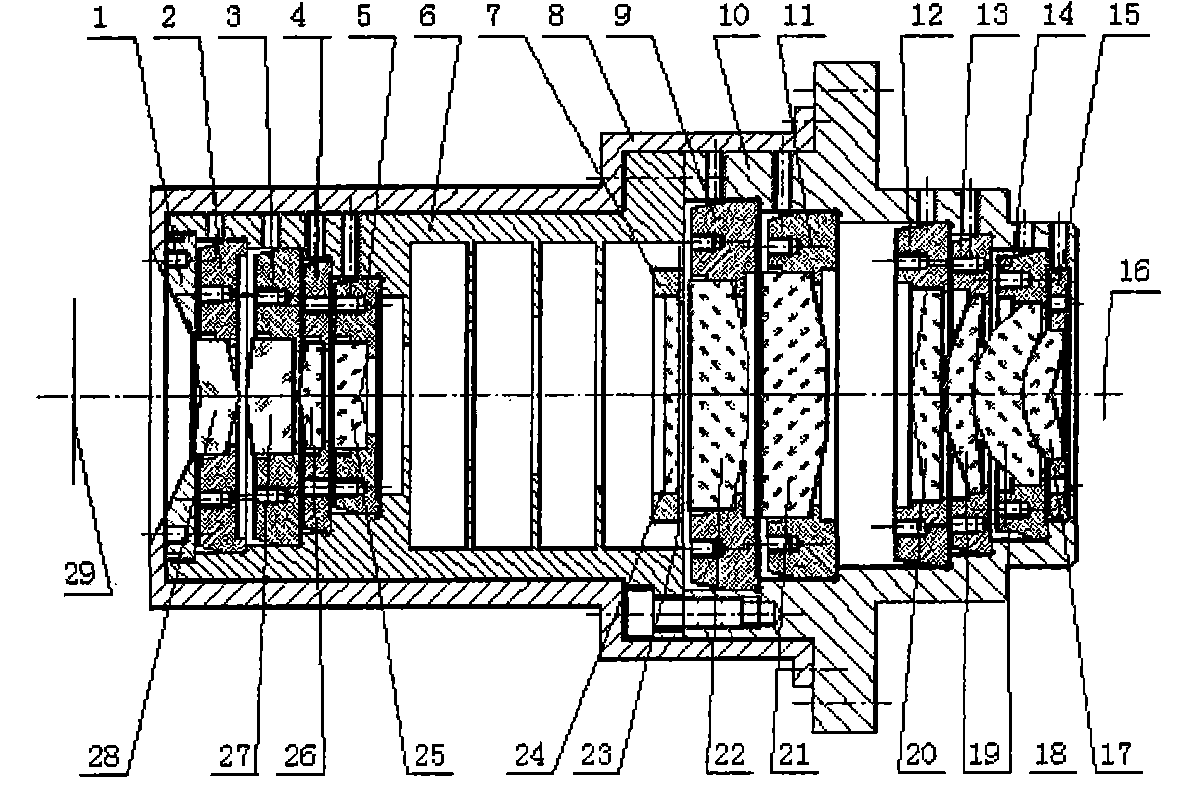

[0026] Such as figure 1 As shown, Embodiment 1 of the present invention includes a three-layer structure of a thermostatic jacket 8, an intermediate layer, an optical lens element and a lens frame assembly. The constant temperature jacket 8 with the clean circulating water of precise constant temperature is the outer layer of the deep ultraviolet projection lithography objective lens. The thermostatic overcoat 8 is sealed outside the lens barrel. The constant temperature coat 8 keeps the temperature of the lens barrel and the optical lens frame assembly, and also separates the optical lens elements in the lens barrel and the space between the elements from the outside atmosphere.

[0027] The middle layer is the lens barrel, which is formed by connecting the first lens barrel 6 and the second lens barrel 10 with connectors. The first lens barrel 6 is equipped with a reinforcing component 7, and the inner wall has mutually parallel step surfaces to support the inner surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com