Projection photoetching objective lens with ultraresolution

A technology of super-resolution and projection light, which is applied in the field of super-resolution projection lithography objective lens, can solve the problems of high price, low resolution, complex structure, etc., and achieve the effects of easy production, increased reduction magnification, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments:

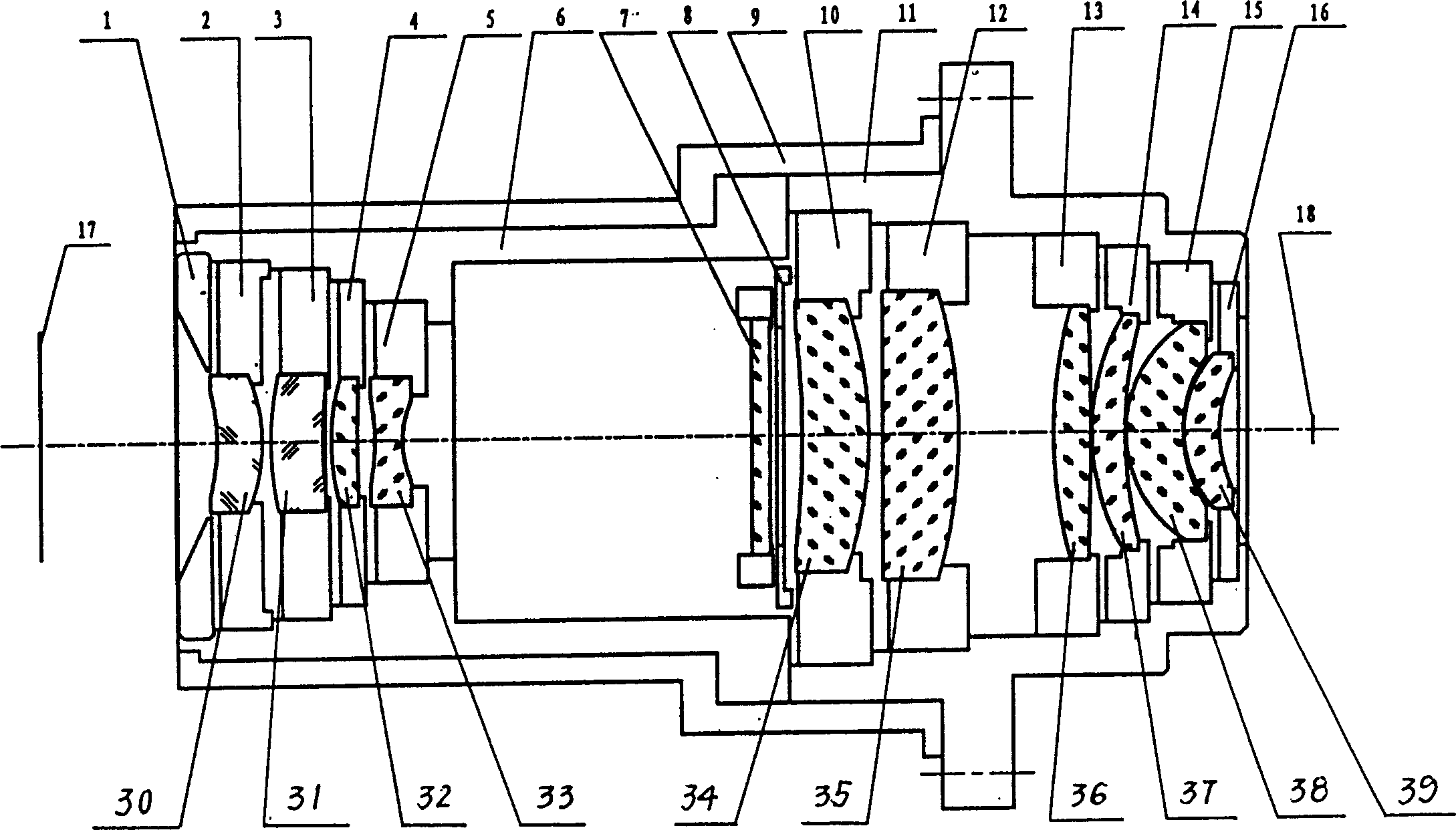

[0018] Such as figure 1 Shown: The super-resolution projection lithography objective lens includes a thermostatic jacket 8, an intermediate layer, an inner layer of optical lens elements and a lens frame assembly.

[0019] The thermostatic jacket 9 with precise thermostatic clean circulating water is the outer layer of the super-resolution projection lithography objective lens. The thermostatic jacket 9 is sealed and fitted on the outside of the lens barrel. The thermostatic jacket 9 keeps the lens barrel and the optical lens frame assembly at a constant temperature, and at the same time separates the optical lens element and the space between the elements in the lens barrel from the outside atmosphere.

[0020] The middle layer is the lens barrel, which is formed by connecting the lens barrel 6 and the lens barrel 11 with connectors. The lens barrel 11 has a flange th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com