Condensed type organic silicon potting material composition with matte surface

A potting material, silicone technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of high cost, blurred picture, etc., and achieve the effect of avoiding reflection, saving cost, and excellent matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Component A: 100 parts of 5000cs 107 glue, 10 parts of 100cs simethicone, 50 parts of stearic acid treated calcium carbonate with a particle size of less than 2μ, Raven M carbon black (American Columbia company), 2 parts of Sipernat 200 precipitation method White carbon black (Degussa);

[0026] B component: 10 parts tetraethoxysilane, 2 parts γ-aminopropyltriethoxysilane, 0.1 part dibutyltin dilaurate;

[0027] Component C: 10 parts of tung oil, 5 parts of castor oil, 10 parts of acrylate modified alkyd resin.

example 2

[0029]A component: 100 parts of 5000cs 107 glue, 10 parts of 100cs simethicone, 50 parts of stearic acid treated calcium carbonate with a particle size of less than 2μ, Raven M carbon black (American Columbia company), 2 parts of Sipernat 200 precipitation method White carbon black (Degussa);

[0030] B component: 10 parts of tetraethoxysilane, 2 parts of γ-aminopropyltriethoxysilane, 0.1 part of dibutyltin dilaurate;

[0031] Component C: 10 parts of tung oil, 5 parts of castor oil, 10 parts of acrylate modified alkyd resin.

example 3

[0033] A component: 100 parts of 5000cs 107 glue, 10 parts of 100cs simethicone, 50 parts of stearic acid treated calcium carbonate with a particle size of less than 2μ, Raven M carbon black (American Columbia company), 2 parts of Sipernat 200 precipitation method White carbon black (Degussa), 0.1 part of zinc naphthenate;

[0034] B component: 10 parts of tetraethoxysilane, 2 parts of γ-aminopropyltriethoxysilane, 0.1 part of dibutyltin dilaurate (Air Products);

[0035] Component C: 10 parts of tung oil, 5 parts of castor oil, 10 parts of acrylate modified alkyd resin.

[0036]

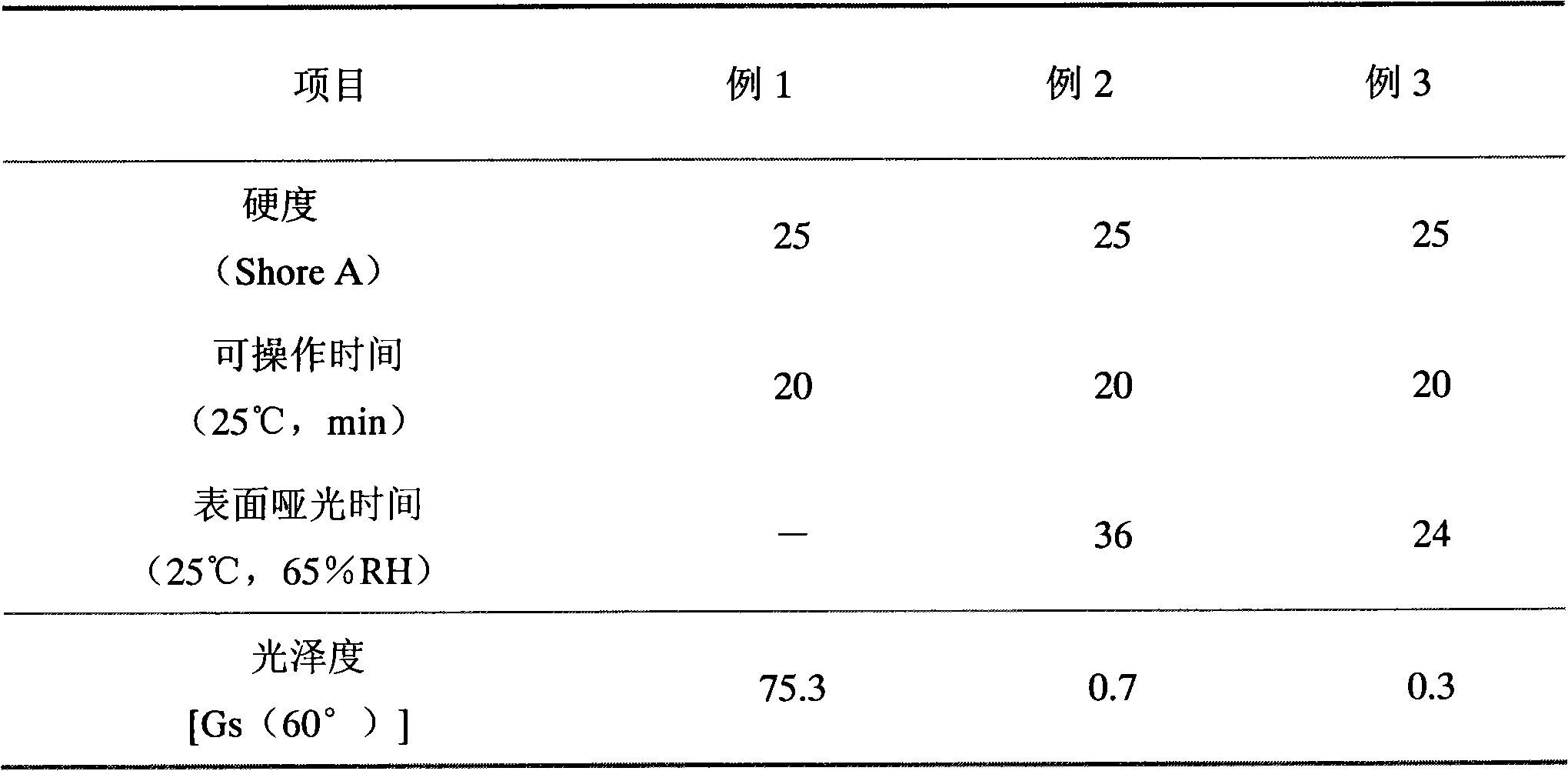

[0037] (Table I)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com