Method for designing LED plane light source structure

A design method and technology of plane light source, applied in the direction of plane light source, light source, electric light source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for designing a LED planar light source structure, the specific steps are as follows:

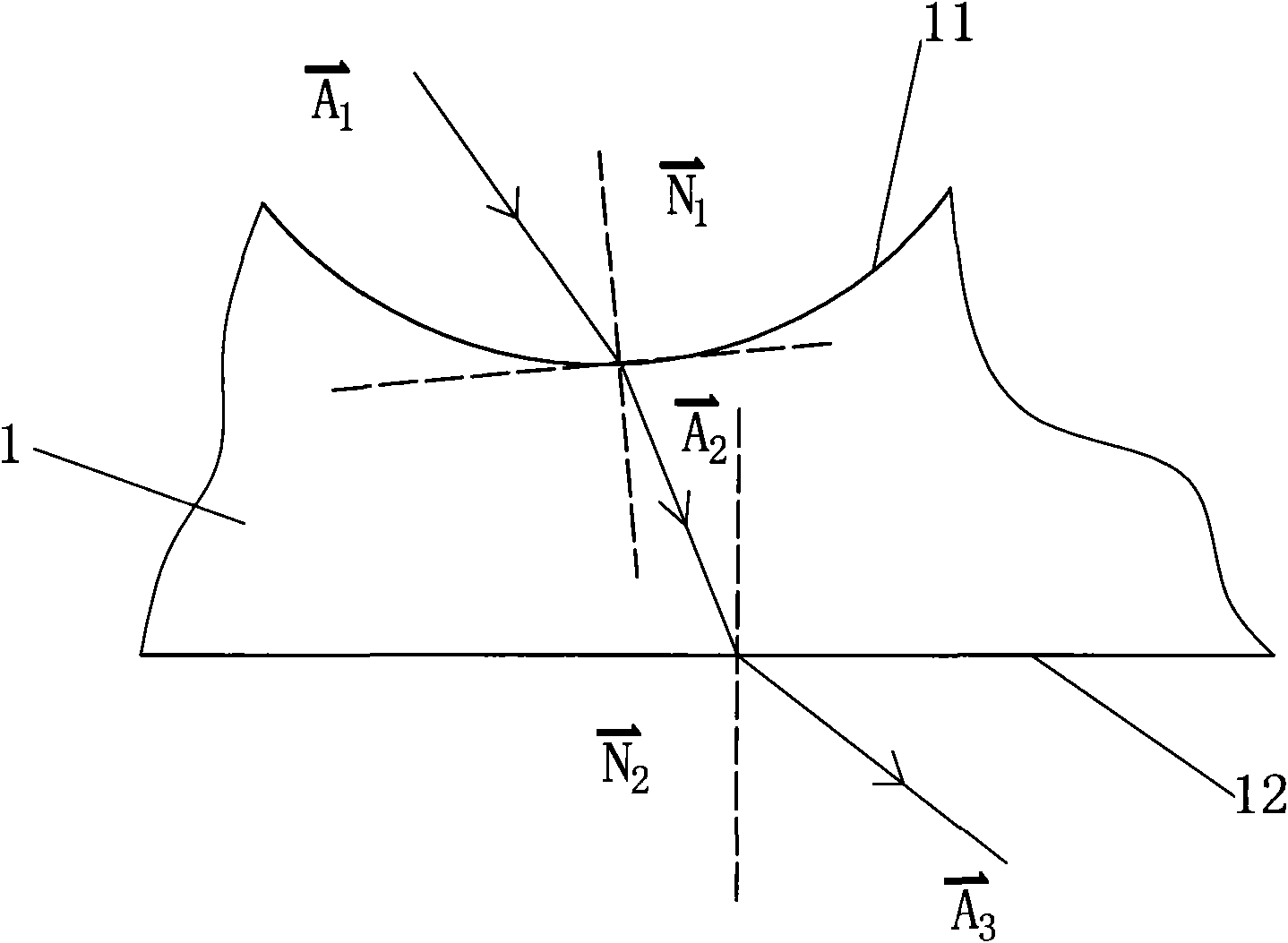

[0027] Such as figure 1 As shown, according to the law of conservation of energy and the law of conservation of luminous flux, the relationship equation between the energy distribution of the light source and the energy distribution of the target illuminated surface is established. The light source uses a Lambertian light-emitting diode, namely Where I is the central light intensity, and a ray incident on the free-form surface 11 of the light-transmitting body 1 is a vector After being refracted by the free-form surface 11, the light enters the medium made of optical resin or engineering plastic, at this time the light is a vector The light on the light-emitting surface 12 of the light-transmitting body enters the air layer from the light-emitting surface 12, and now the light is in is the angle of the light rays from the light source, is the angle of light inciden...

Embodiment 2

[0041] Such as image 3 The light source design steps and light design steps of the second embodiment shown are the same as those in the first embodiment, except that in the design step of the solid model of the free-form surface of the light-transmitting body, the shape of the solid model of the free-form surface of the light-transmitting body is made into a hexagonal shape. In the design step of the light guide plate, the solid model of the free-form surface of the hexagonal light-transmitting body is combined according to the method of honeycomb staggered arrangement to obtain an integrated light guide plate with dimming ability.

Embodiment 3

[0043] Such as image 3 As shown, the design steps of the light source, the light source and the solid model of the free-form surface of the light-transmitting body in the third embodiment are the same as those in the first embodiment. The solid model is combined according to the method of honeycomb staggered arrangement to obtain an integrated light guide plate with dimming ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com