Antibacterial blended yarn and application thereof

A yarn and weight percentage technology, which is applied in the field of textile fabrics, can solve problems such as easy occurrence of moths, mildew and nourishment of bacteria, affecting the appearance, life and hygiene of wool fabrics, etc., to achieve antibacterial improvement, cost reduction, and washing resistance sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

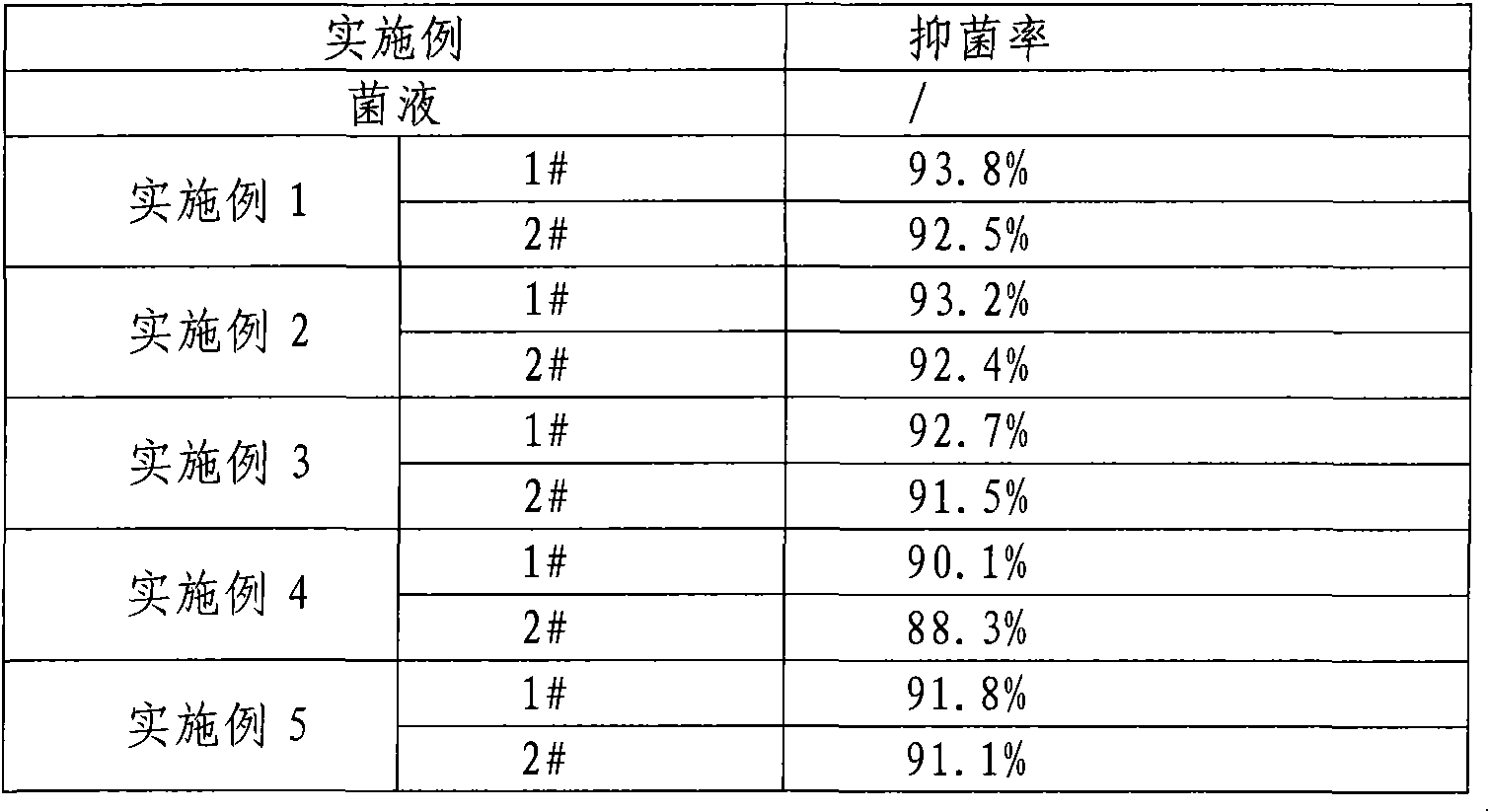

Examples

Embodiment 1

[0018] A kind of antibacterial sweater and production technology thereof are as follows:

[0019] (1) select gray yarn raw material: select to be 40% hemp fiber (purchased from Shanxi Oasis Textile Co., Ltd.), 20% modal fiber (purchased from Lenzing Company), 20% high elastic polyester fiber (purchased from Shanxi Oasis Textile Co., Ltd.) by weight percentage Purchased from Jiangsu Yizheng Chemical Fiber Textile Co., Ltd., specification 200D / 2), 20% viscose fiber (purchased from Jilin Chemical Fiber Group) blended yarn as raw material; Modal (MODAL) is a kind of regenerated cellulose fiber, The Austrian Lenzing Company uses European beech wood, which is made by beating and spinning. The raw materials are 100% natural, harmless to the human body, can be decomposed naturally, and are harmless to the environment.

[0020] (2) Dyeing: Dye the gray yarn according to the design color of the fabric. The dyeing temperature is controlled at 65°C-70°C for 30-40 minutes, and the drying t...

Embodiment 2

[0030] Except gray yarn raw material, other implementation conditions are identical with embodiment 1.

[0031] In this embodiment, the gray yarn raw material is selected from the yarn blended with 39% hemp fiber, 15% modal fiber, 24% high elastic polyester fiber and 22% viscose fiber by weight percentage as raw material.

Embodiment 3

[0033] Except gray yarn raw material, other implementation conditions are identical with embodiment 1.

[0034] In this embodiment, the gray yarn raw material is selected from the yarn blended with 40% hemp fiber, 15% modal fiber, 25% high elastic polyester fiber and 20% viscose fiber by weight percentage as raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com