Methyl methacrylate-styrene copolymer containing fluoro-acrylate and preparation method thereof

A technology of methyl methacrylate and styrene copolymer, which is applied in the field of synthesis of fluorine-containing acrylate copolymers, can solve the problems of low conversion rate of fluorine-containing monomers and unstable emulsion, etc., and achieves low cost and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

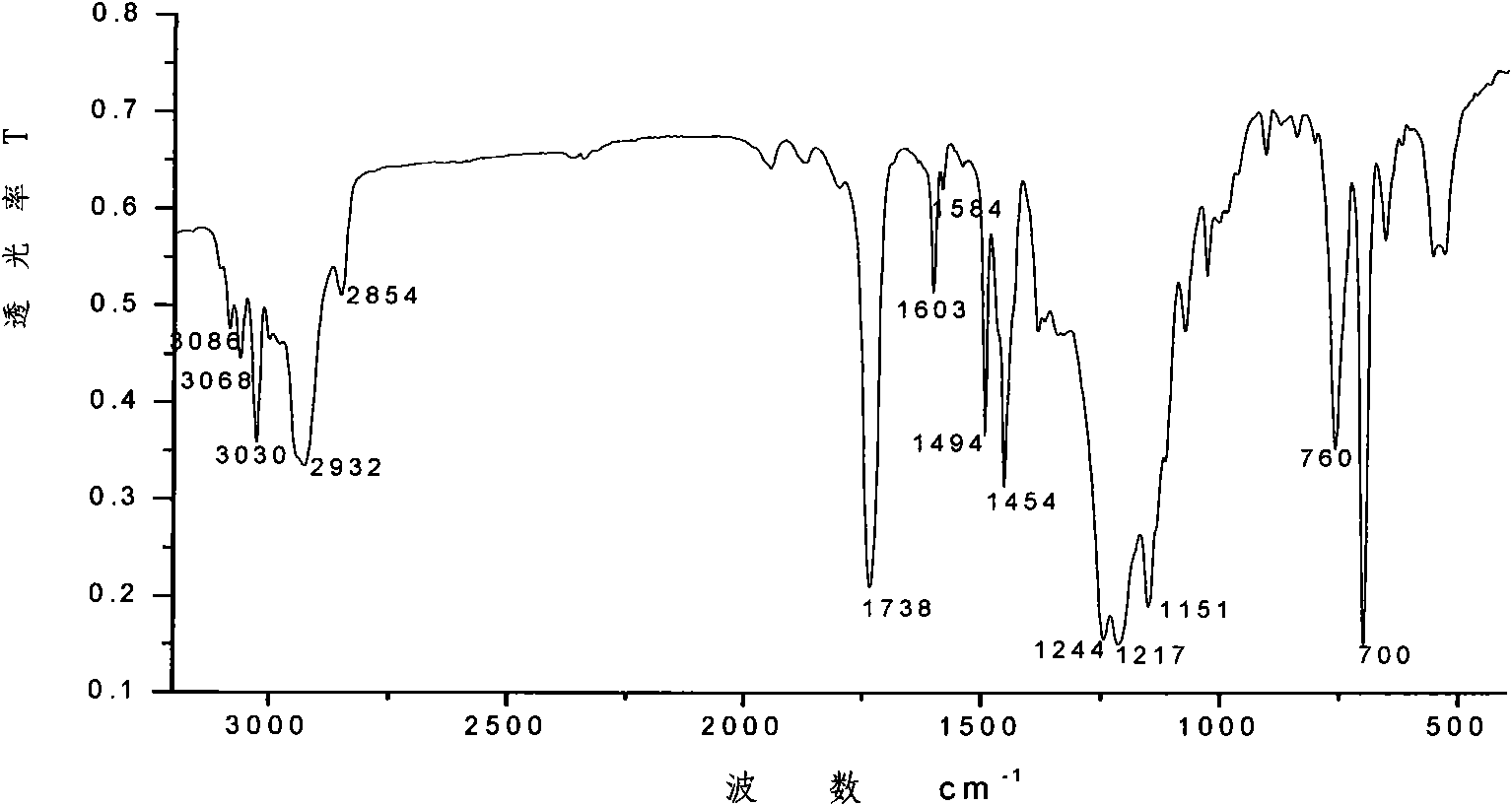

Image

Examples

Embodiment 1

[0029] Add 0.25 grams of sodium dodecyl sulfate (SDS), 0.25 grams of nonylphenol polyoxyethylene ether (OP-10), 0.8 grams of tetrafluoropropanol, 0.4 grams of n-butanol, 1.0 gram of perfluoroalkyl ethyl acrylate (FA), 2.4 grams of methyl methacrylate (MMA), 2.4 grams of styrene (St), 43 grams of distilled water, pre-emulsified at 40°C at a stirring speed of 2500 rpm After 30 minutes, the pre-emulsion was obtained, and then 2 / 3 of the pre-emulsion was poured into the constant pressure dropping funnel, and after the four-necked bottle was filled with nitrogen and deoxygenated for 30 minutes (the following reaction process was kept under a nitrogen atmosphere), the temperature was raised to 80 ℃, add 0.06 gram of potassium persulfate (KPS), 0.03 gram of sodium bisulfite (NaHSO 3 ), reacted for 1.5 hours, and then used 2 hours to drop all the pre-emulsion liquid previously removed from the constant pressure dropping funnel into the four-necked flask. After the dropwise addition, t...

Embodiment 2

[0042] Add 0.25 g of SDS, 0.5 g of OP-10, 0.9 g of tetrafluoropropanol, 0.3 g of n-butanol, 1.5 g of perfluoroalkyl ethyl acrylate (FA), 2.4 g of methyl Methyl acrylate (MMA), 2.4 grams of styrene (St), 43 grams of distilled water, pre-emulsified for 30 minutes at 35 ° C, 3000 rpm stirring speed, and then pour 2 / 3 of the pre-emulsion into the constant pressure drop in the funnel. Fill the system with nitrogen and oxygen for 30 minutes (the following reaction process is kept under nitrogen atmosphere), the system is heated to 78°C, and 0.05 grams of KPS and 0.025 grams of NaHSO are added to the remaining pre-emulsion in the four-necked bottle 3 , reacted for 1.5 hours, then added dropwise the mixed solution in the constant pressure dropping funnel to the four-neck flask for 3 hours, and reacted for 4 hours after the addition was completed, and kept at 78°C for the reaction. After the reaction, use ethanol or saline to break the emulsification. Suction filtration, washing with...

Embodiment 3

[0047] Add 0.3 g of SDS, 0.45 g of OP-10, 0.8 g of tetrafluoropropanol, 0.4 g of n-butanol, 2.0 g of perfluoroalkyl ethyl acrylate (FA), 2.4 g of methyl Methyl acrylate (MMA), 2.4 grams of styrene (St), 43 grams of distilled water, pre-emulsified at 45 ° C for 30 minutes at a stirring speed of 2500 rpm, and then poured 2 / 3 of the pre-emulsion into the constant pressure drop in the funnel. Fill the system with nitrogen and oxygen for 30 minutes (the following reaction process is kept under nitrogen atmosphere), the system is heated up to 70 ° C, and 0.1 g of AIBN is added to the remaining pre-emulsion in the four-necked bottle, reacted for 1.5 hours, and then added dropwise with constant pressure drops The mixed solution in the funnel was kept at 70° C. for 5 hours to react. After the reaction, use ethanol or saline to break the emulsification. Suction filtration, washing with water, and drying to obtain the final product;

[0048] A component: take by weighing 0.05 gram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com