A kind of vdc/ma copolymerized pvdc composition

A composition and copolymerization technology, which is applied in the field of VDC/MA copolymerized PVDC composition, can solve problems such as not being fully satisfactory, and achieve the effects of white film color, thermal stability and improved processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

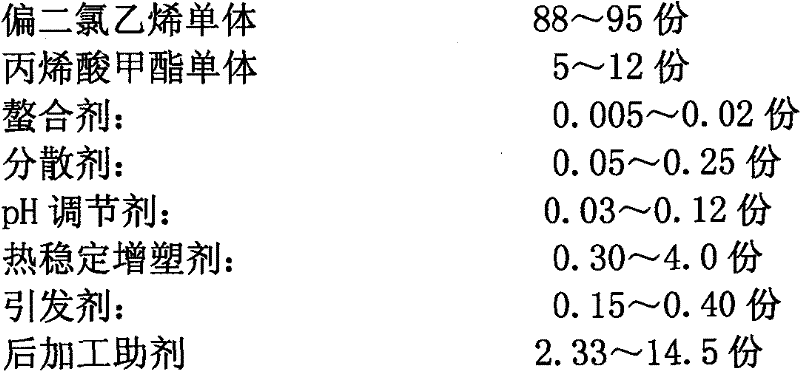

[0036] A VDC / MA copolymerized PVDC composition, its raw material formula is as follows;

[0037] Vinylidene chloride (VDC) 31.85kg

[0038] Methyl acrylate (MA) 3.15kg

[0039] Deionized water: 55kg

[0040] pH regulator: sodium pyrophosphate 25g

[0041] Initiator: tert-butyl peroxy-2-ethylhexanoate 90g

[0042] Lauryl Peroxide 15g

[0043] Dispersant: methyl cellulose ether 55g

[0044] Chelating agent: disodium ethylenediaminetetraacetic acid (EDTA) 4g

[0045] Heat stable plasticizer: epoxy linseed oil 0.8kg

[0046] Lubricant: Stearic Acid Amide 60g

[0047] Oleamide 30g

[0048] Interface layer improver: ethylene-vinyl acetate copolymer (EVA) 2kg

[0049] The preparation steps are as follows:

[0050] In a 100L stainless steel polymerization kettle (length-to-diameter ratio: 2:1, double-layer two-leaf 45° oblique paddle), put 55kg of deionized water, 4g of disodium edetate, 55g of methyl cellulose ether, and 25g of pyrophosphoric acid Sodium, 180g epoxy linsee...

Embodiment 2

[0053]Repeat embodiment 1, the difference between the present embodiment and embodiment 1 is that following components are:

[0054] (1) Vinylidene chloride (VDC) 31.5kg

[0055] (2) Methyl acrylate (MA) 3.5kg

[0056] (3) Chelating agent: disodium cycloethylene diamine tetraacetate (DCTA) 4g

[0057] (4) Heat-stable plasticizer: epoxy soybean oil 0.8kg

[0058] Result: the obtained weight average molecular weight (M W ) is a copolymerized PVDC composition of 79375, the molecular weight dispersion index is 2.158, and the viscosity value is 1.414.

Embodiment 3

[0060] Repeat embodiment 1, the difference between the present embodiment and embodiment 1 is that following components are:

[0061] (1) Vinylidene chloride (VDC) 32.55kg

[0062] (2) Methyl acrylate (MA) 3.5kg

[0063] (3) Interface layer improver: chlorinated polyethylene 3kg

[0064] (4) Lubricant: stearic acid amide 50g

[0065] Oleamide 50g

[0066] Result: the obtained weight average molecular weight (M W ) is a copolymerized PVDC composition of 88458, the molecular weight dispersion index is 2.392, and the viscosity value is 1.481.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com