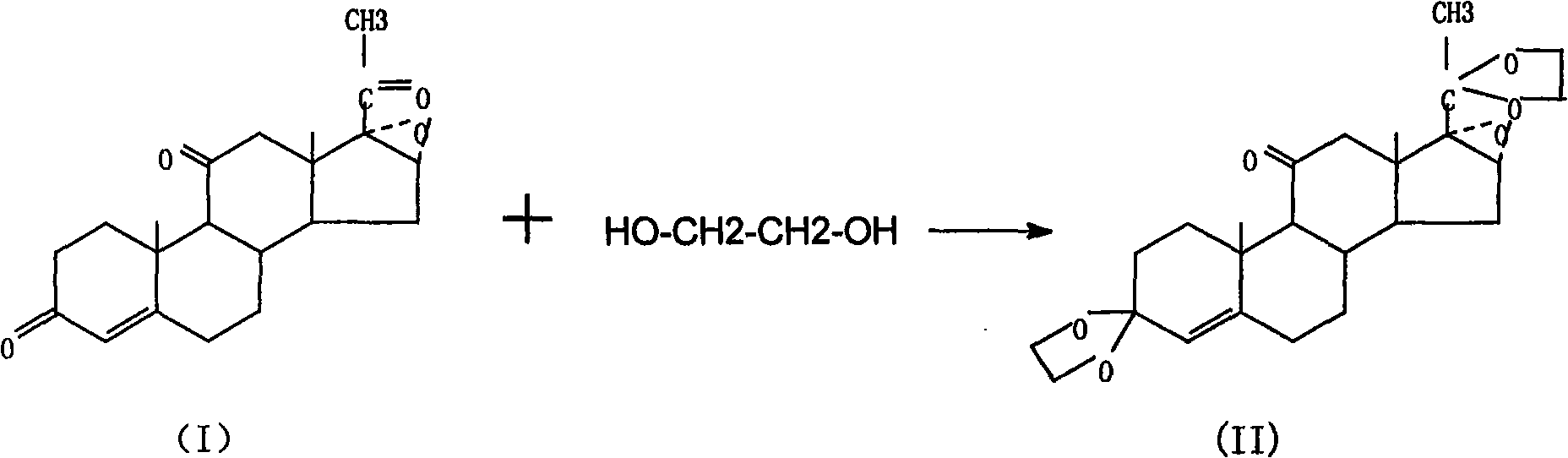

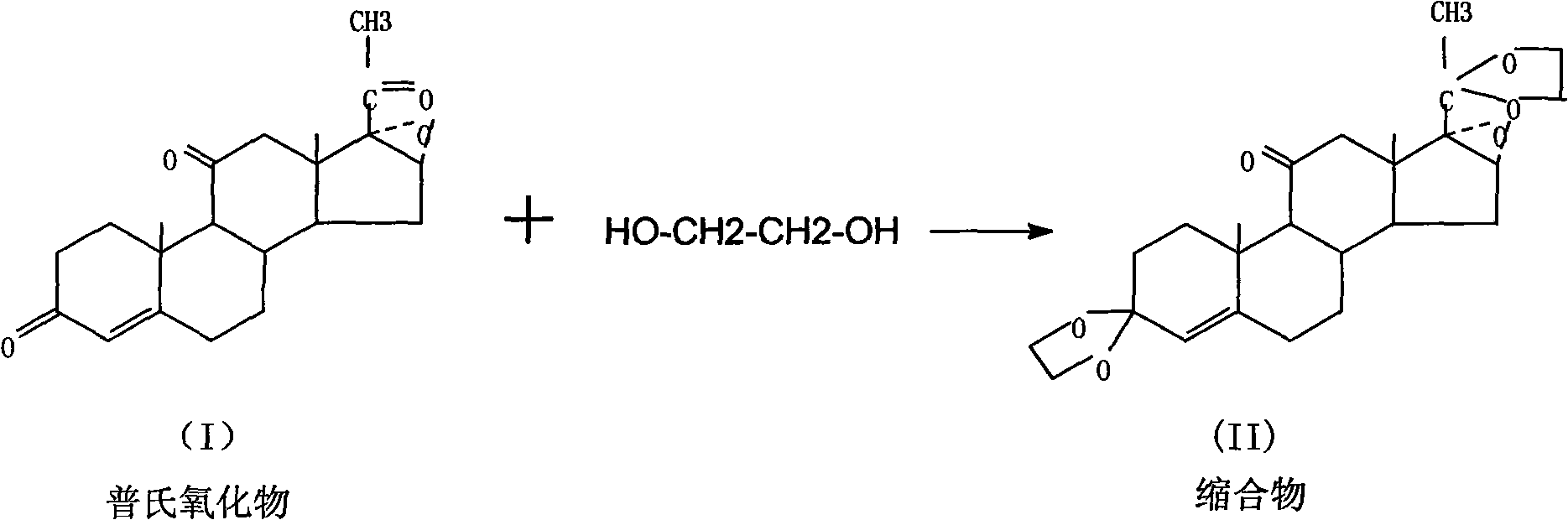

Process method for producing intermediate 3,20-diethylene glycol of betamethasone serial products

A series of products, the technology of betamethasone, applied in the field of chemical medicine, can solve the problems of serious equipment loss and energy consumption, unsatisfactory condensate quality, and great human poisoning, so as to reduce equipment loss, shorten reaction time, and reduce harm and the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Example 1: Comparative example, traditional preparation process

[0010] Using the existing production process for preparing the condensate of betamethasone series products, 70g of cortisone acetate intermediate Platts oxide, 383g of ethylene glycol, and 1218g of benzene were added into the reaction flask, and stirred at 75-80℃ for refluxing and separating water for 1 hour. , Adding 0.7 g of p-toluenesulfonic acid and continuing to stir and reflux at 80°C for 10 hours, and the reaction is complete. It was concentrated under reduced pressure until crystals precipitated, cooled to 10°C, filtered, and dried to obtain 68.5 g of condensate, with an HPLC content of 86%.

Embodiment 2

[0011] Example 2: Process of the present invention

[0012] Add 70g of cortisone acetate intermediate Platts oxide, 196g of ethylene glycol, 80g of triethyl orthoformate, 140g of chloroform, and 1.5g of boron trifluoride-diethyl ether into the reaction flask, and stir to react at 20-25°C. After 5 hours, the reaction was complete. It was concentrated under reduced pressure until crystals precipitated, cooled to 10°C, filtered, and dried to obtain 75 g of a condensate with a HPLC content of 90%.

Embodiment 3

[0013] Example 3: Process of the present invention

[0014] Add 70g of Cortisone acetate intermediate Platts oxide, 196g of ethylene glycol, 80g of triethyl orthoformate, 140g of methylene chloride, and 1.5g of boron trifluoride-diethyl ether into the reaction flask, and stir to react at 20-25°C. After 5 hours, the reaction was complete. It was concentrated under reduced pressure until crystals precipitated, cooled to 10°C, filtered, and dried to obtain 75.3 g of a condensate with an HPLC content of 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com