Coal chemical wastewater treating technique

A coal chemical wastewater and wastewater treatment technology, applied in biological water/sewage treatment, heating water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of large amount of adsorbent, high COD value and high cost, and achieve The effect of good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

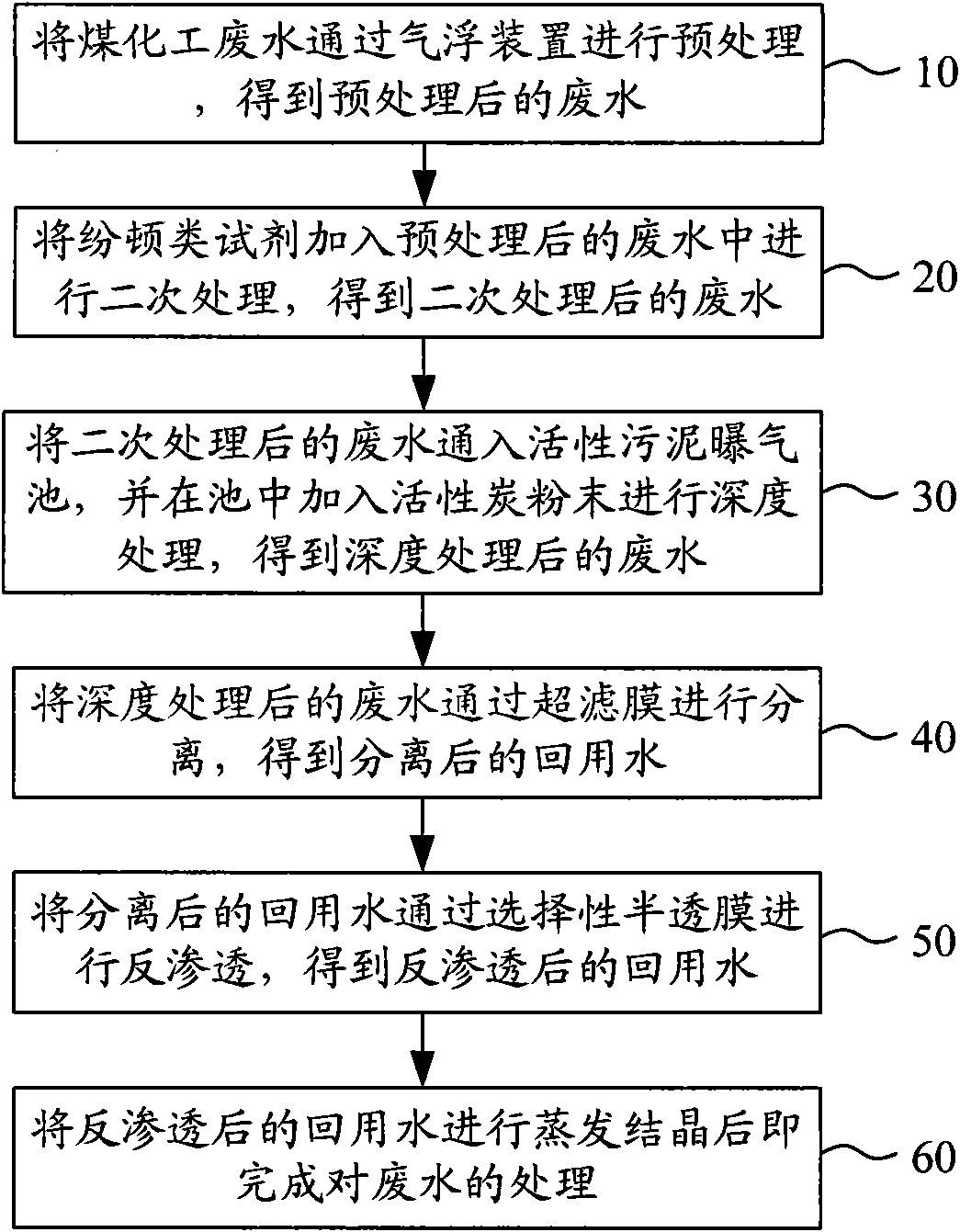

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0026] figure 1 It is a process flow chart of the coal chemical industry wastewater treatment process of the present invention. Such as figure 1 As shown, the process includes the following steps:

[0027] Step 10, pretreating the coal chemical industry wastewater through an air flotation device to obtain pretreated wastewater.

[0028] Excessive oil in wastewater will affect the effect of subsequent biochemical treatment. The role of air flotation method for coal chemical wastewater pretreatment is to remove oil and recycle it. In addition, air flotation is useful for separating inorganic and organic suspended solids and removing dissolved substances in water. Sexual organics also have some effect.

[0029] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com