Method for preparing zirconium hydride

A technology of surface treatment and zirconium hydride, which is applied in the direction of transition element hydride, etc., can solve the problems of substrate microcracks, difficulty in hydrogen barrier film layer, easy cracking and peeling of film layer, etc., achieve low production cost, solve the problem of hydrogen loss, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Cut zirconium hydride with a hydrogen-zirconium atomic ratio of about 1.8 into a Φ20mm×10mm cylindrical sample. The samples were ultrasonically cleaned with acetone for 15 minutes and then dried.

[0030] The pretreated zirconium hydride sample is placed in a vacuum tube resistance furnace for high-temperature thermal oxidation treatment, so that a zirconium oxide hydrogen barrier film layer is formed on the surface of the zirconium hydride. The specific steps are as follows: put the zirconium hydride sample into a stainless steel crucible, then put it into a vacuum tube resistance furnace, start the mechanical pump, vacuumize, extract the air in the crucible, and then inject CO into the crucible. 2 To 0.1MPa, start heating. The temperature rise rate during the heating process is 1°C / min. When the temperature reaches 350°C, keep it warm for 60 hours, then cut off the power supply, and cool down with the furnace to form a zirconia hydrogen barrier film layer.

[0031]...

Embodiment 2

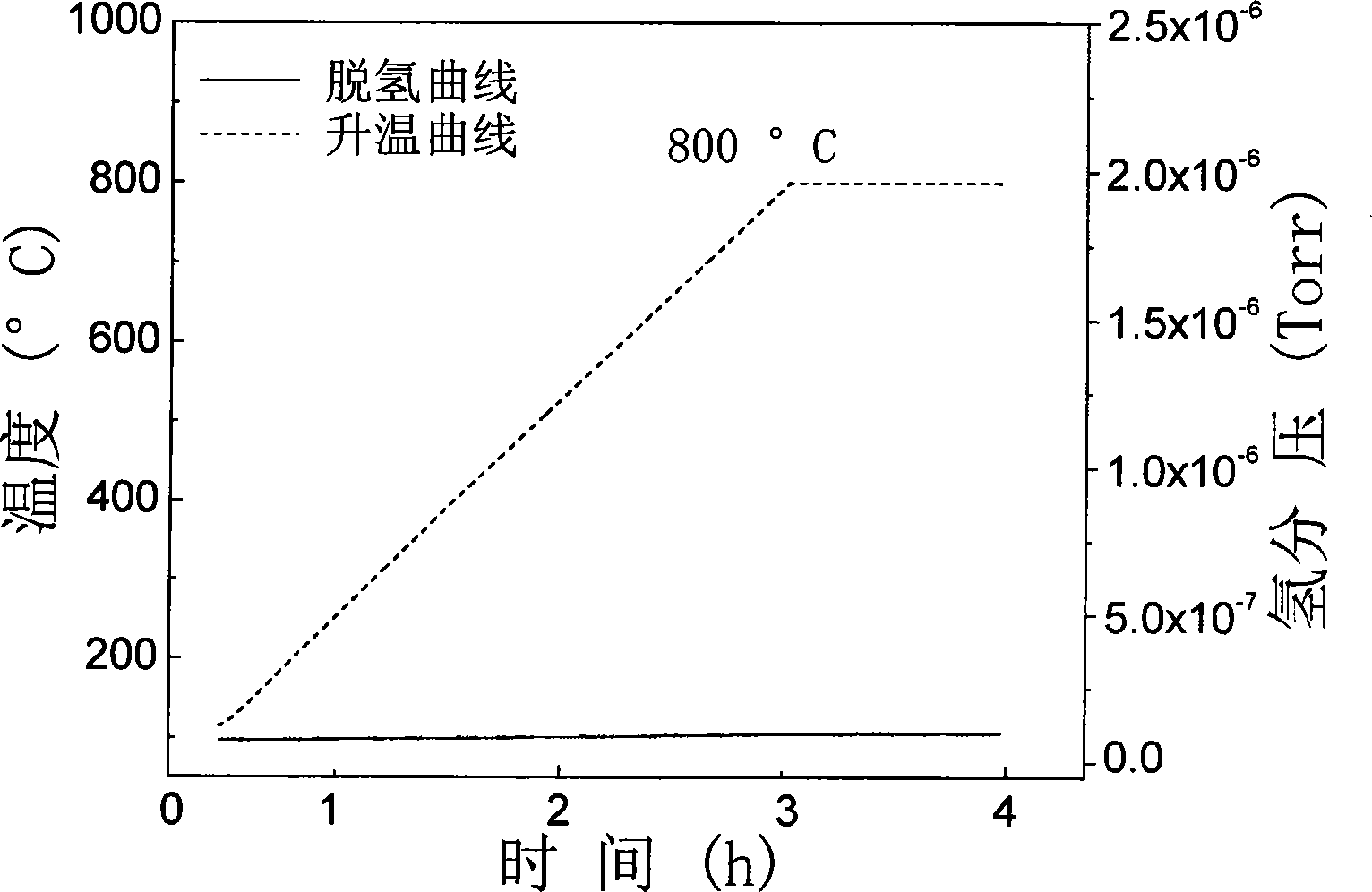

[0033] Cut zirconium hydride with a hydrogen-zirconium atomic ratio of about 1.8 into a Φ20mm×10mm cylindrical sample. The samples were ultrasonically cleaned with acetone for 20 minutes and then dried.

[0034] The pretreated zirconium hydride sample is placed in a vacuum tube resistance furnace for high-temperature thermal oxidation treatment, so that a zirconium oxide hydrogen barrier film layer is formed on the surface of the zirconium hydride. The specific steps are as follows: put the zirconium hydride sample into a stainless steel crucible, then put it into a vacuum tube resistance furnace, start the mechanical pump, vacuumize, extract the air in the crucible, and then inject CO into the crucible. 2 To 0.1MPa, start heating. The heating rate during the heating process is 5°C / min. When the temperature reaches 600°C, keep it warm for 30 hours, then cut off the power supply, and cool down with the furnace to form a zirconia hydrogen barrier film layer.

[0035] The oxidi...

Embodiment 3

[0037] Cut zirconium hydride with a hydrogen-zirconium atomic ratio of about 1.8 into a Φ20mm×10mm cylindrical sample. The samples were ultrasonically cleaned with acetone for 20 minutes and then dried.

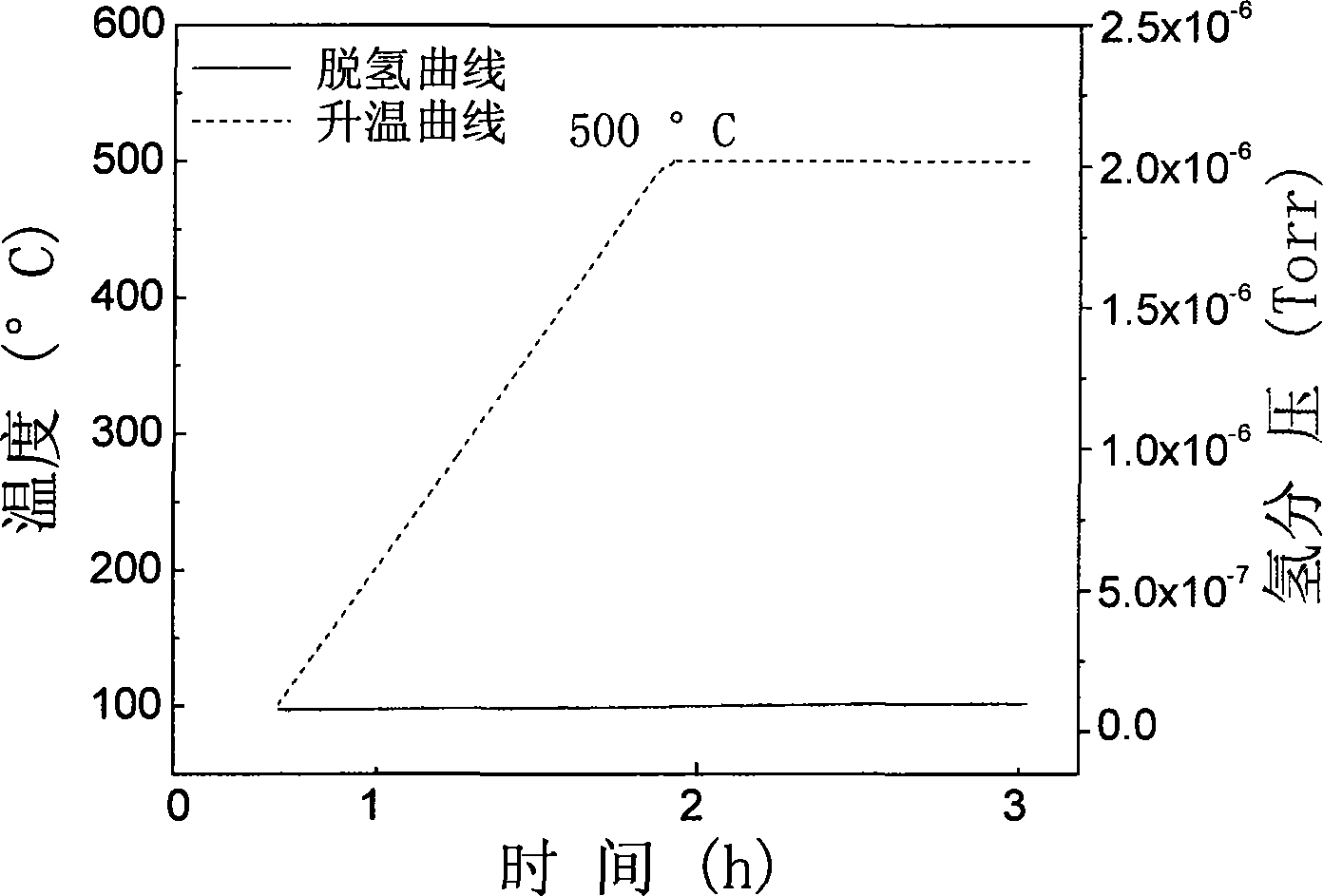

[0038] The pretreated zirconium hydride sample is placed in a vacuum tube resistance furnace for high-temperature thermal oxidation treatment, so that a zirconium oxide hydrogen barrier film layer is formed on the surface of the zirconium hydride. The specific steps are as follows: put the zirconium hydride sample into a stainless steel crucible, then put it into a vacuum tube resistance furnace, start the mechanical pump, vacuumize, extract the air in the crucible, and then inject CO into the crucible. 2 To 0.1MPa, start heating. The heating rate during the heating process is 2°C / min. When the temperature reaches 500°C, keep it warm for 40 hours, then cut off the power supply, and cool down with the furnace to form a zirconia hydrogen barrier film layer.

[0039] The oxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com