Method for producing leadless brazing alloy salient point by laser

A lead-free solder and laser technology, applied in laser welding equipment, manufacturing tools, semiconductor/solid-state device manufacturing, etc., can solve the problem of oversized solder bump size device packaging, slow solder bump production speed, and automation No problems such as high level, to achieve the effect of reducing processing cost, fast processing speed and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

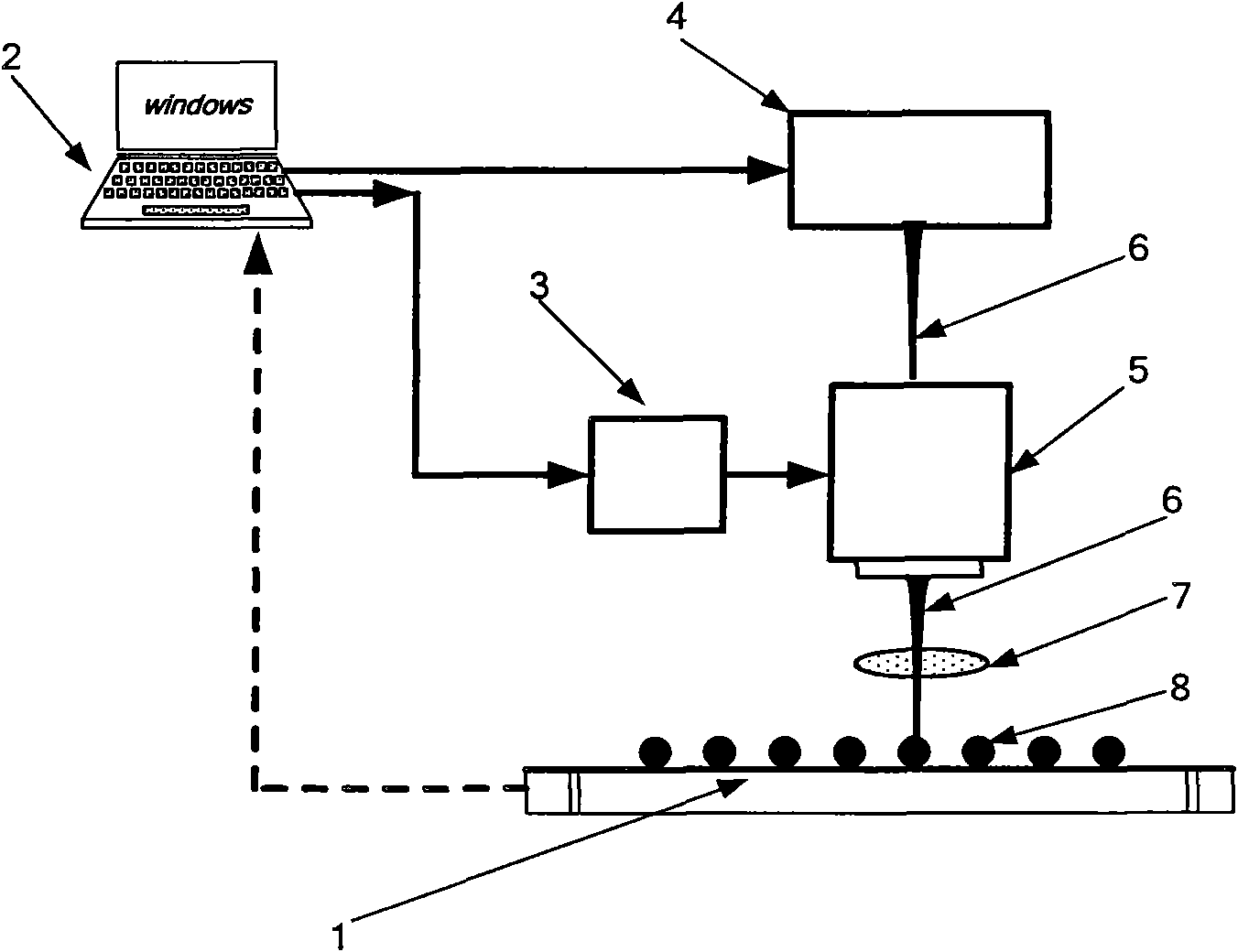

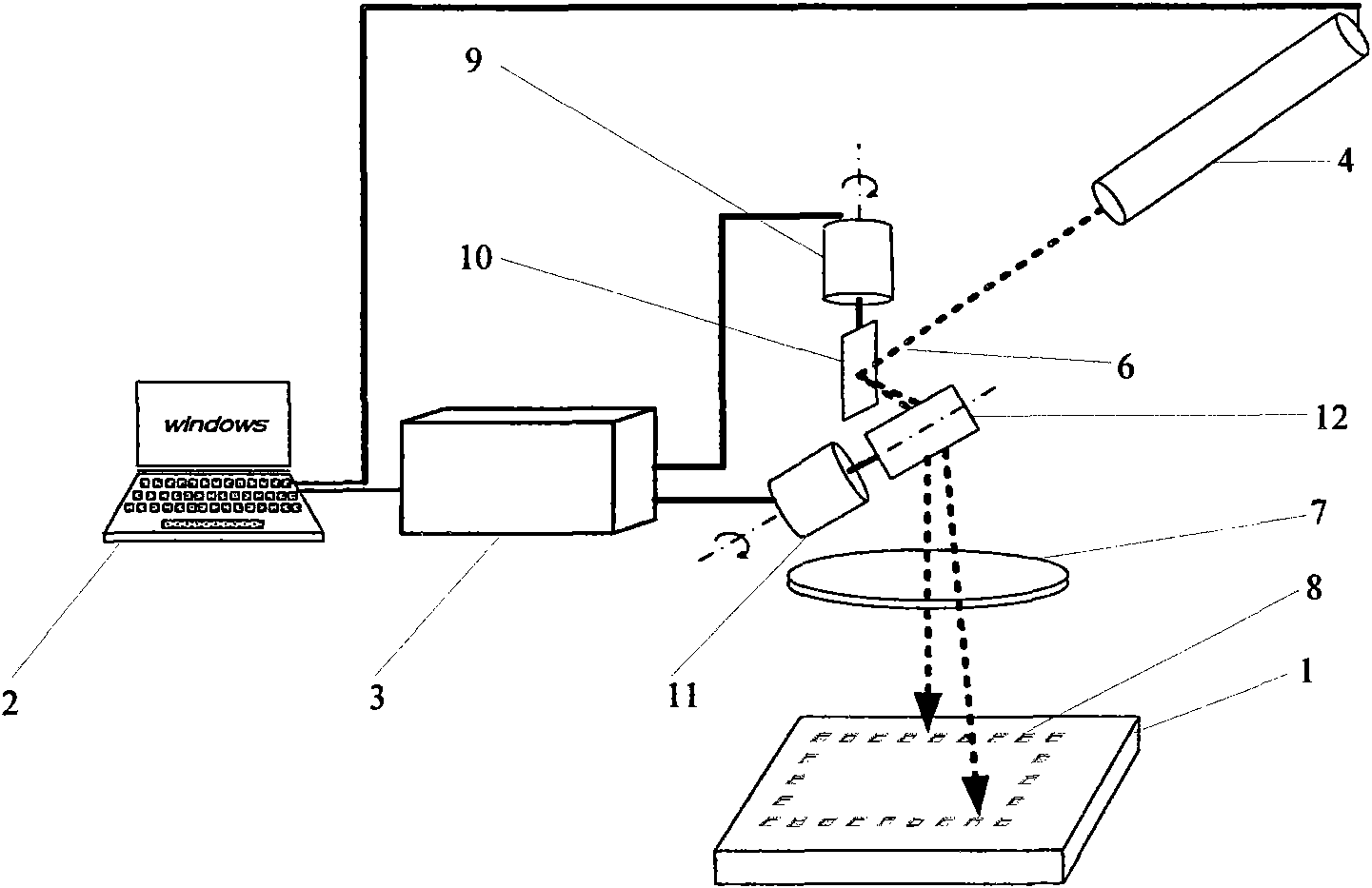

[0034] In this embodiment, a method of laser making lead-free solder bumps, such as figure 1 As shown in the schematic diagram of the system structure, it specifically includes the following steps:

[0035] (1) Apply lead-free solder on the position where the substrate 1 is used for ball planting (i.e., the making of solder bumps), and place the substrate 1 coated with lead-free solder on the processing plane of the laser manufacturing system (i.e. On the focal plane of the f-θ flat-field lens 7 in the laser production system);

[0036] (2) Input the position data of the ball planting place of the substrate 1 into the computer 2, and the programmed program (ie path planning program) in the computer 2 will update the data, and plan the ball planting path according to the position data of the ball planting place ;

[0037] (3) The computer 2 forms a control signal with the planned ball planting path, and sends it to the control unit 3 and the laser 4 respectively through the U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com