Method for preparing semiconductor gallium nitride (GaN) extending thin film substrate

An epitaxial thin film, gallium nitride technology, applied in semiconductor/solid state device manufacturing, electrical components, circuits, etc., can solve problems such as defects, insufficient mechanical stability, high stress, etc., to achieve less defect density and reduce epitaxial stress. and defect density, the effect of small epitaxial stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] (1) Use GaN thin films epitaxially grown on sapphire substrates;

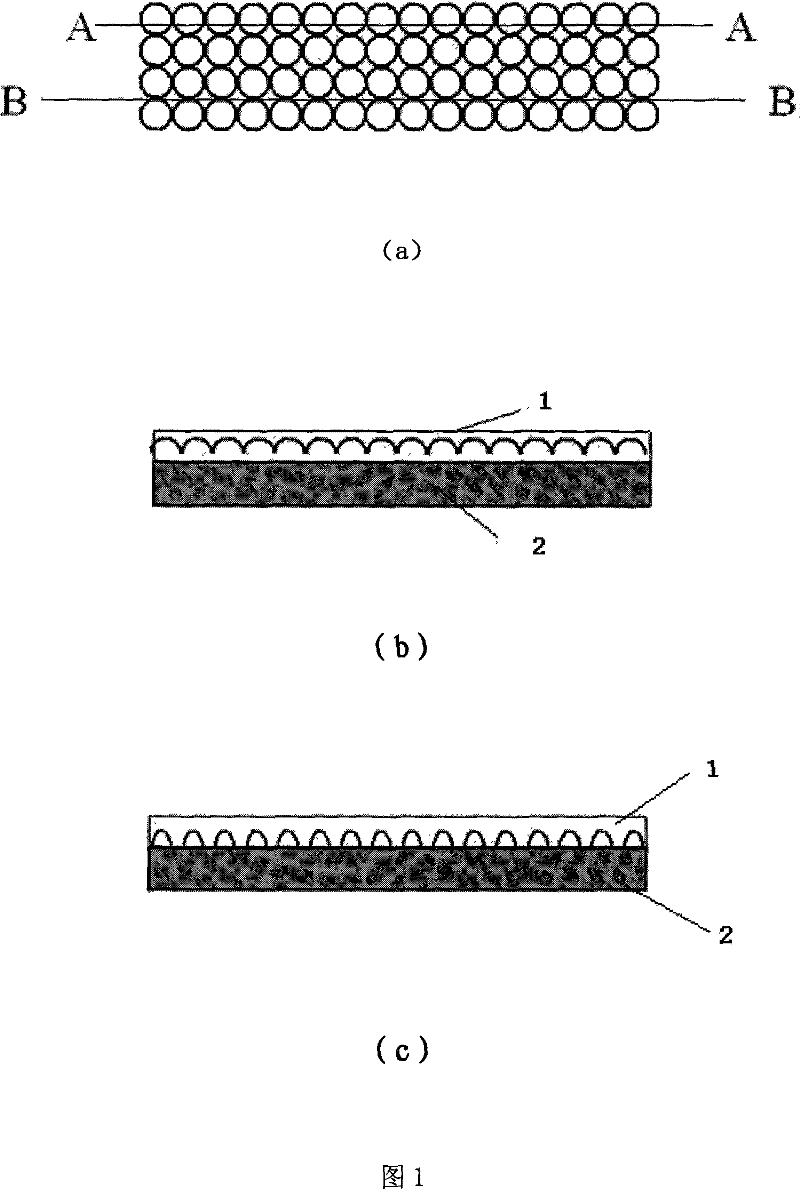

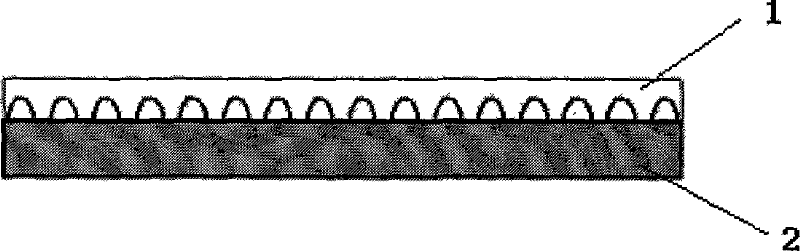

[0025] (2) Use an excimer pulsed ultraviolet laser (Lambda 203D, laser wavelength 248 nm) to form a focused laser beam. Focused micro laser beam forming as attached figure 1 Array graphics shown in a. The focused micro-laser beam is irradiated on the GaN epitaxial film to form a square array pattern, in which the part with high energy density of the focused micro-laser beam is a dot, and the part outside the dot is a part with relatively low energy.

[0026] The pattern of the focused micro-laser beam array in the present invention can be formed by shielding and focusing.

[0027] (3) The focused micro-laser beam is incident on the GaN epitaxial film from the direction of the sapphire substrate. By adjusting the energy density of the laser beam (about 400 mJ / cm2) figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com