Copolymer comprising 4-hydroxybutyrate unit and lactate unit and its manufacturing method

A technology of lactate terpolymer and hydroxybutyrate, which is applied in DNA/RNA fragments, recombinant DNA technology, fermentation, etc., can solve the problem of complex preparation methods of high-molecular-weight PLA and the difficulty of removing solvents or chain coupling agents , did not disclose the preparation of copolymers and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

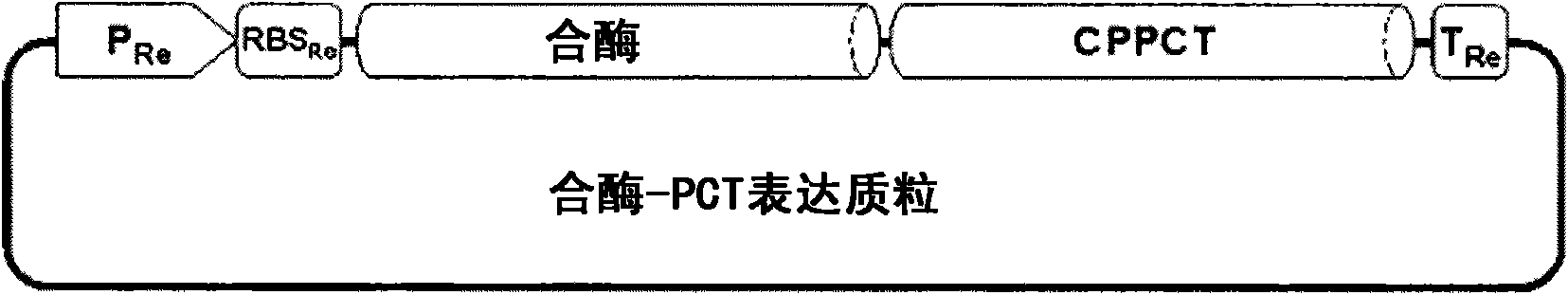

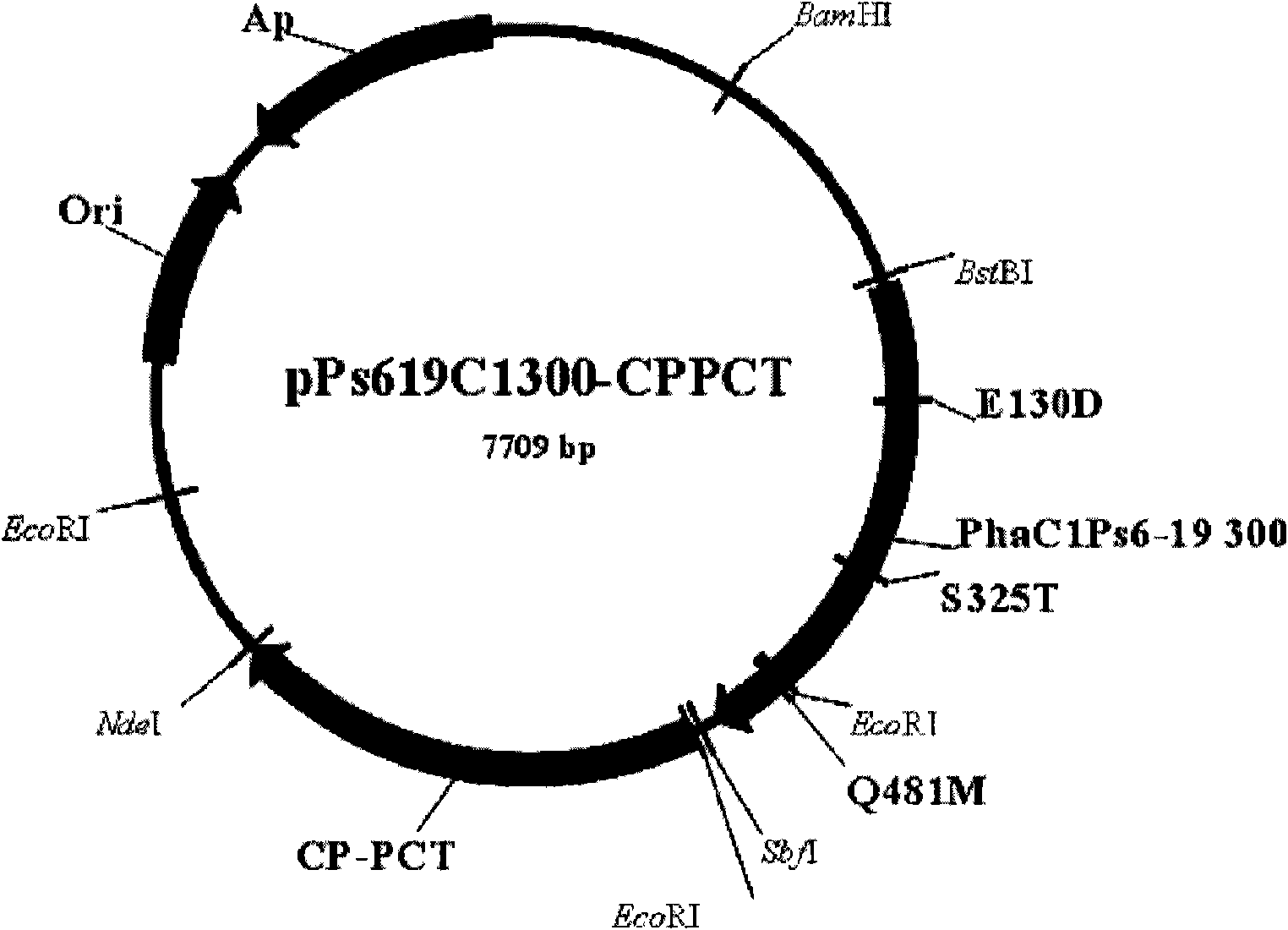

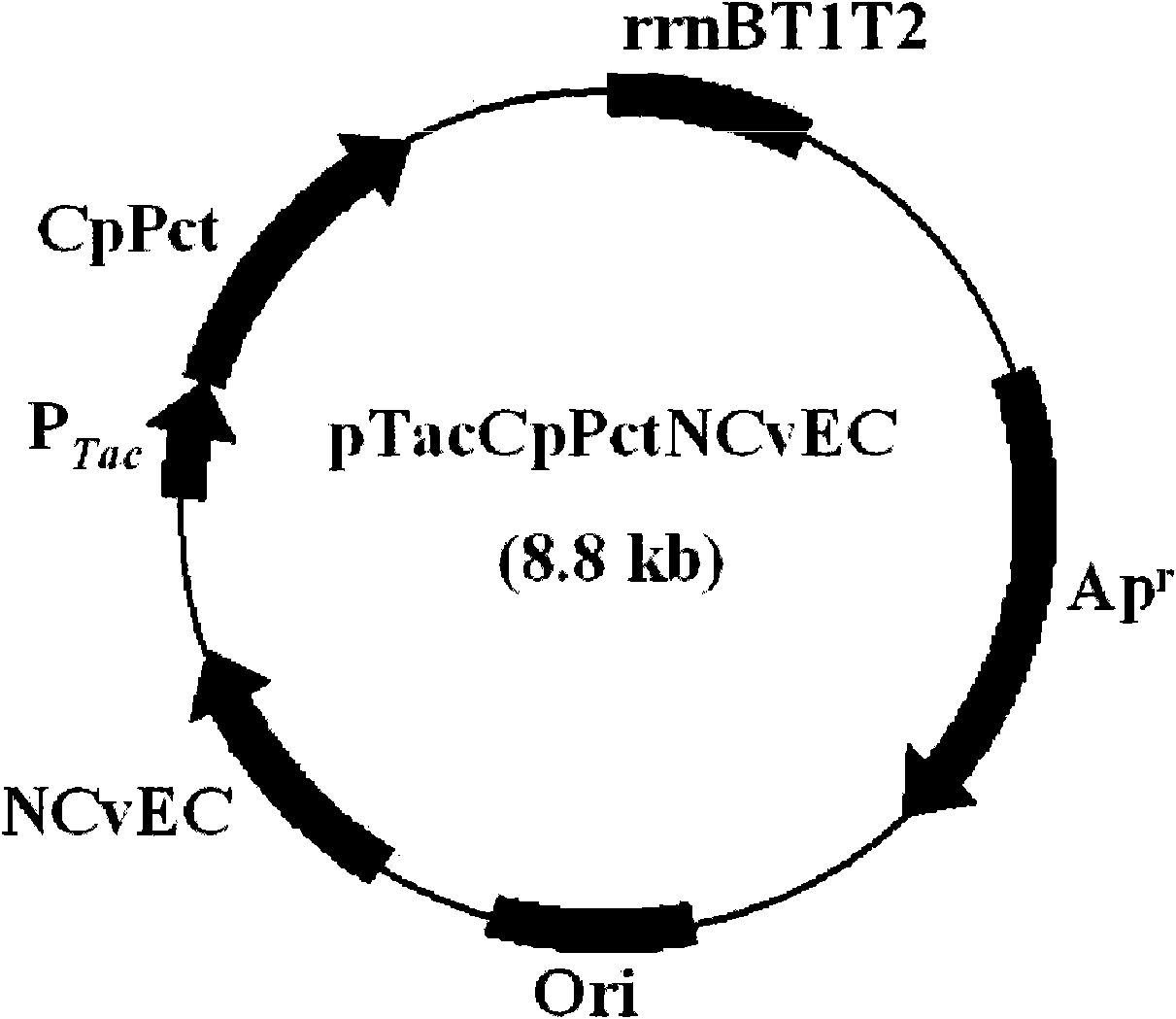

[0040] Example 1: Construction of a recombinant plasmid comprising pct gene and PHA synthase gene.

[0041] Recombinant plasmids pPs619C1300-CPPCT and pTacCpPctNCvEC containing pct gene and PHA synthase gene were constructed to prepare copolymers containing 4-hydroxybutyrate unit and lactate unit.

[0042] (1) Construction of plasmid pPs619C1300-CPPCT

[0043] The propionyl-CoA transferase (CP-PCT) gene derived from Clostridium propionicum was used as the pct gene, and the PHA synthase gene derived from Pseudomonas 6-19 was used as the PHA synthase gene .

[0044] Such as figure 1 An operon for a constitutive expression system expressing PHA synthase and CP-PCT together was constructed. CP-PCT is known to be toxic to host microorganisms. In other words, in the tac promoter or T7 promoter expression system induced by IPTG, which is widely used for the expression of recombinant proteins, all microorganisms die within a short time after the addition of the inducer. For this ...

Embodiment 2

[0083] Embodiment 2: Preparation of 4-hydroxybutyrate-lactate copolymer

[0084] E. coli Top 10 (Invitrogen) was transformed with pPs619C1300-CPPCT obtained in Example 1 together with pMCSPtbBuk to obtain E. coli Top 10 / pPs619C1300-CPPCT / pMCSPtbBuk.

[0085] The 4-hydroxybutyrate-lactate copolymer was obtained by cultivating the transformant in the following two steps: firstly, the transformed recombinant E. Vegetable LB medium (Bacto TM Tryptone (BD) 10g / L, Bacto TM After culturing in yeast extract (BD) 5 g / L, NaCl (amresco) 10 g / L) for 24 hours, the medium was centrifuged at 4° C. at 1000 g for 15 minutes to collect cells.

[0086] The collected cells were cultured in MR medium (glucose 10 g, KH 2 PO 4 6.67g, (NH 4 ) 2 HPO 4 4g, MgSO 4 ·7H 2 O 0.8g, citric acid 0.8g and trace metal solution 5mL; trace metal solution composition: 5M HCl 5mL per L, FeSO 4 ·7H 2 O 10g, CaCl 2 2g, ZnSO 4 ·7H 2 O 2.2g, MnSO 4 4H 2 O 0.5g, CuSO 4 ·5H 2 O 1g, (NH 4 ) 6 Mo 7 ...

Embodiment 3

[0089] Embodiment 3: Preparation of 4-hydroxybutyrate-3-hydroxypropionate ester terpolymer

[0090] In addition to MR medium containing 2g / L 4-hydroxybutyrate (4-HB), 2g / L 3-hydroxypropionate (3-HP), 100mg / L ampicillin and 30mg / L chloramphenicol Instead of anaerobically culturing the collected cells in MR medium containing 2g / L 4-HB, 100mg / L ampicillin and 30mg / L chloramphenicol for 3 days, prepare 4-hydroxybutyrate according to the method of Example 2 - 3-Hydroxypropionate-lactate terpolymer.

[0091] As a result of the analysis, methyl-4-hydroxybutyrate, methyl-3-hydroxypropionate, and methyl-lactate were detected in the E. coli Top10 / pPs619C1300-CPPCT / pMCSPtbBuk transformant, which means that by Preparation of Novel 4-Hydroxybutyrate-3-Hydroxypropionate-Lactate Terpolymers [Poly(4-Hydroxybutyrate-Co-3-Hydroxypropionate-Co-Lactate) acid ester)]. The obtained 4-hydroxybutyrate-3-hydroxypropionate-lactate terpolymer 1 H-NMR and GC-MSD results are shown in Image 6 with 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com