Sealed ceramic lining composite oil tube and manufacturing method thereof

A composite oil pipe and ceramic lining technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor sealing and corrosion resistance at the coupling, high manufacturing cost, and achieve the effect of reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

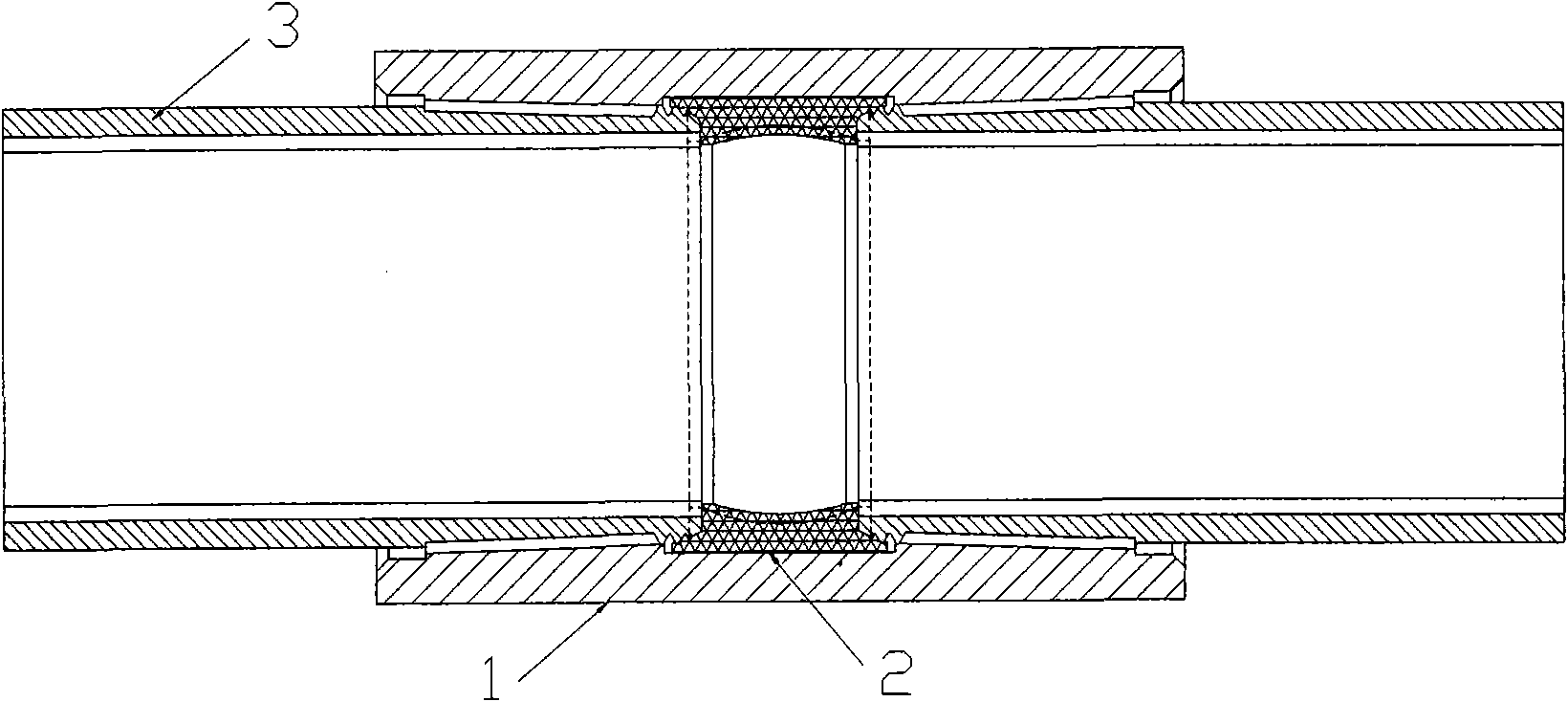

[0019] refer to figure 1 , figure 2 , the present invention includes a ceramic-lined composite oil pipe 3, a coupling 1, a corrosion-resistant boronizing layer is provided on the inner and outer surfaces of the coupling, a flat groove is opened in the middle of the inner wall of the coupling, and a nitrile rubber sealing ring 2 is arranged in the flat groove. The rubber seal ring and the end face of the ceramic-lined composite oil pipe are tightly fitted and sealed. The two ends of the NBR seal ring are processed with trapezoidal grooves 4, and the inside is processed with grooves 5. In the groove of the end, the deformation of the nitrile rubber sealing ring is between 1.5-2.5mm, and the nitrile rubber squeezes the inner groove of the sealing ring close to the flat state, so as to achieve the sealing effect.

[0020] Concrete manufacturing method comprises the following steps:

[0021] 1. Grooving inside the coupling: use a lathe to process flat grooves at a position 46mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com