CaSO* crystal whisker with desulfurized gypsum as raw material and preparing method

A technology for desulfurizing gypsum and calcium sulfate whiskers, which is applied in chemical instruments and methods, single crystal growth, crystal growth, etc. It can solve the problems of certain requirements for equipment compressive strength and inconvenient operation, and achieves mild conditions and easy operation. The effect of simplicity and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of CaSO using desulfurized gypsum as raw material 4 Whiskers and their preparation method: first fully mix desulfurization gypsum, water and crystallization agent to form a suspension, wherein: the mass concentration of desulfurization gypsum is 1-3%, and the mass concentration of crystallization agent is 5-9%;

[0024] Under normal pressure, 100-128°C and a stirring rate of 120-160r / min, stir the above suspension for 3-5 hours, add sodium oleate with a mass of 0.5-0.7% of the suspension, and stir for 0.5-0.6 hours ; Then filter and wash, and finally dry at 45-60°C for 2-4 hours to obtain calcium sulfate hemihydrate whiskers.

[0025] The composition and mass concentration of the crystallization agent in this embodiment are: sulfuric acid 1-3%, calcium chloride 4-6%.

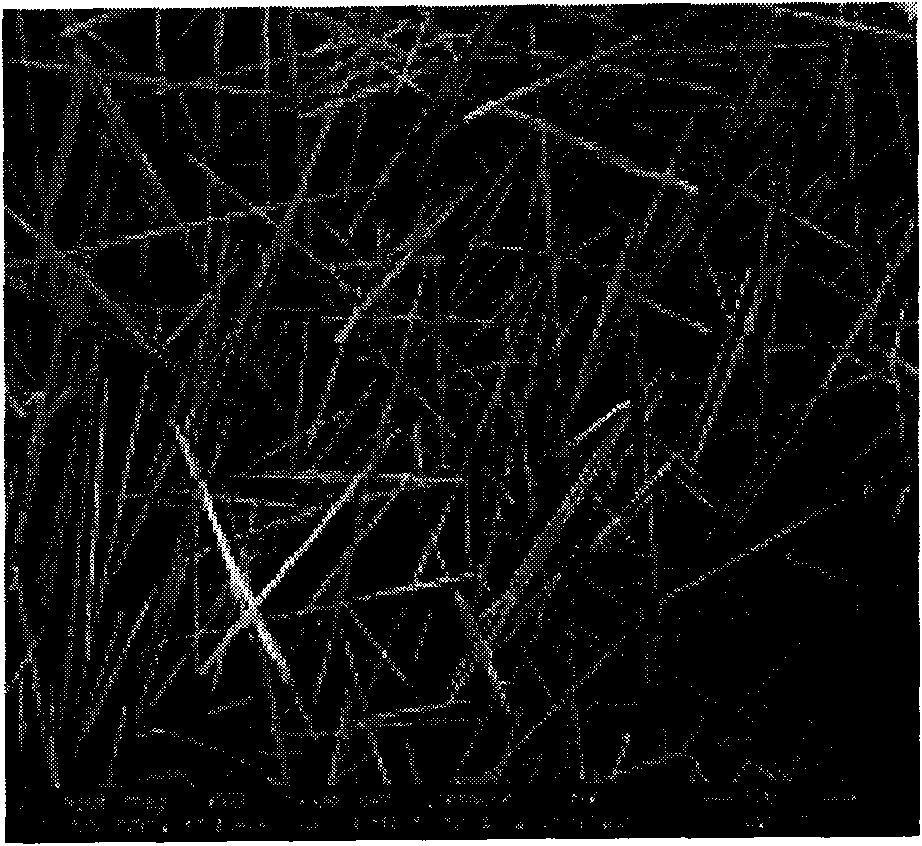

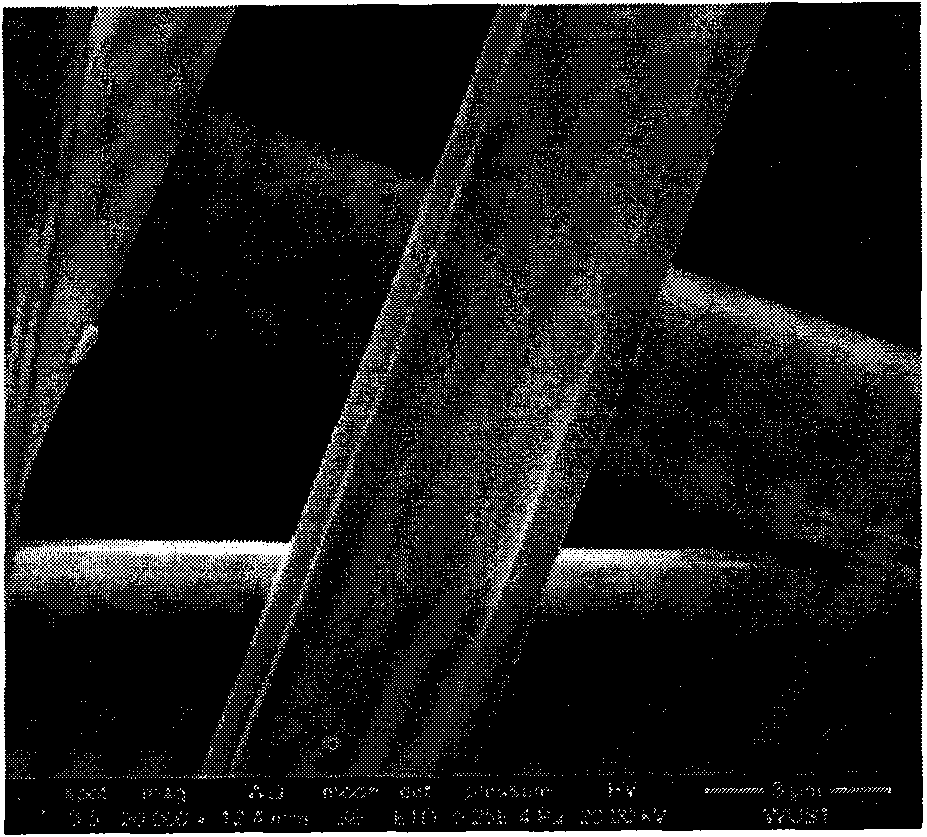

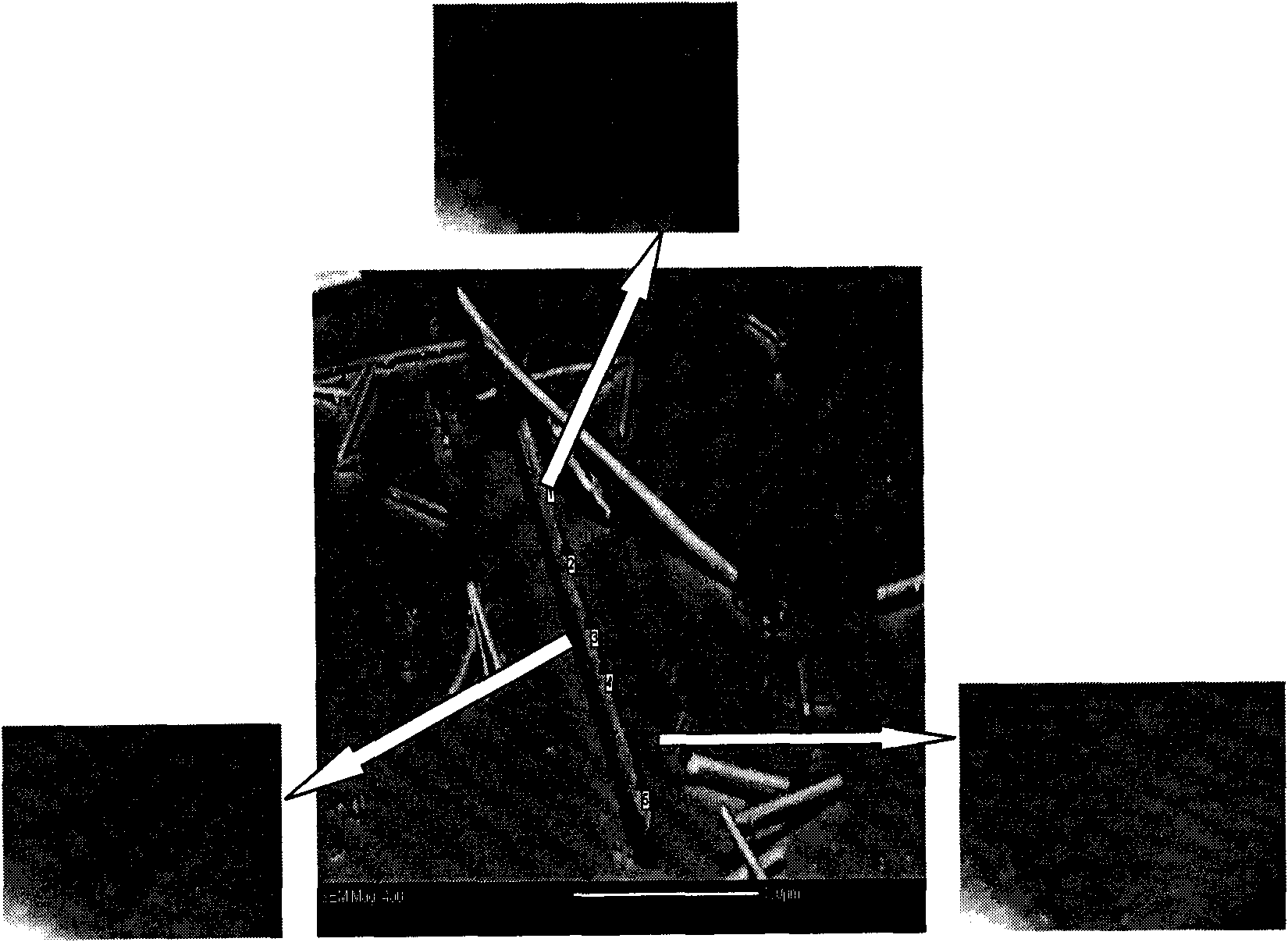

[0026] The CaSO prepared in this example 4 Whiskers, the length of which is 280-300 μm, the diameter is 1-4 μm, the modified CaSO 4 Whiskers have good stability and compatibility.

Embodiment 2

[0028] A kind of CaSO using desulfurized gypsum as raw material 4 Whiskers and their preparation method: first fully mix desulfurization gypsum, water and crystallization agent to form a suspension, wherein: the mass concentration of desulfurization gypsum is 1-3%, and the mass concentration of crystallization agent is 5-9%;

[0029] Under the conditions of normal pressure, 100-128°C and stirring rate of 140-180r / min: Stir the above suspension for 1-3 hours, add calcium sulfate whiskers with a mass of 0.5-1% of the suspension as seeds, and react After 1-3 hours, add sodium oleate with a mass of 0.5-0.7% of the suspension, and stir for 0.5-1 hour. Then, it is filtered and washed, and finally dried at 45-60° C. for 2-4 hours to obtain calcium sulfate hemihydrate whiskers.

[0030] The composition and mass concentration of the crystallization agent in this embodiment are: sulfuric acid 1-3%, calcium chloride 4-6%.

[0031] The CaSO prepared in this example 4 Whiskers, the whis...

Embodiment 3

[0033] A kind of CaSO using desulfurized gypsum as raw material 4 Whiskers and their preparation method: first fully mix desulfurized gypsum, water and crystallization agent to form a suspension, wherein the mass concentration of desulfurization gypsum is 2-5%, and the mass concentration of crystallization agent is 8-10%.

[0034] Under the conditions of normal pressure, 100-128°C and a stirring rate of 140-180r / min, the above suspension was stirred for 5-7 hours, and sodium dodecylbenzenesulfonate with a mass of 0.8-1% of the suspension was added, Stir for 0.6-0.7 hours; then filter and wash, and finally dry at 60-400°C for 2-4 hours to obtain anhydrous soluble calcium sulfate whiskers.

[0035] The composition and mass concentration of the crystallization agent in this embodiment are: 1-1.5% of sulfuric acid, 5-6% of calcium chloride, and 2-2.5% of magnesium chloride.

[0036] The CaSO prepared in this example 4 Whiskers, the whisker length is 200-240 μm, the diameter is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com