Ginger cola health drink and preparation technology thereof

A technology of health drink and preparation technology, which is applied in the field of food processing industry, can solve problems such as developmental impact and adverse health, and achieve the effect of pleasant taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

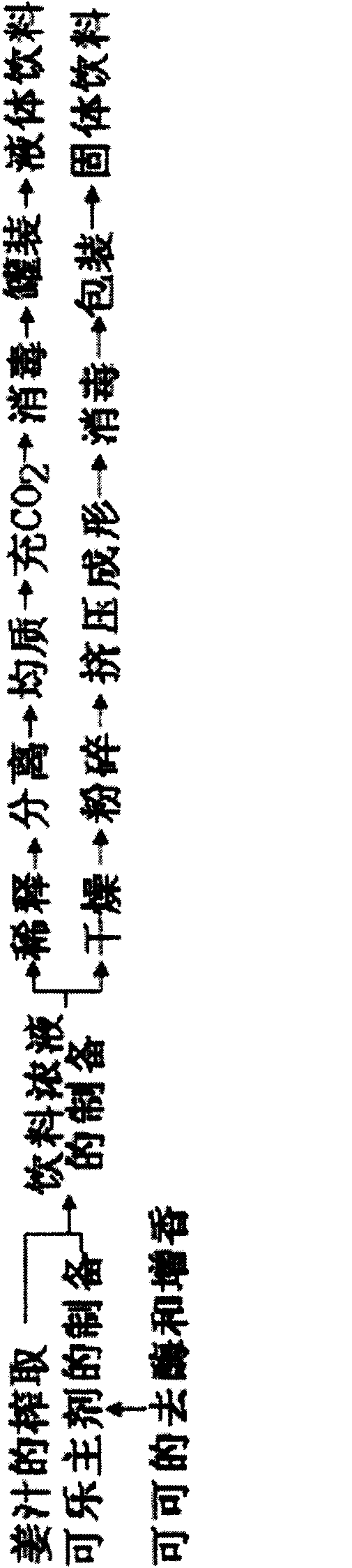

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Preparation method of natural cola main agent (1)

[0017]After washing 500 kg of fresh cocoa beans, add them to boiling water, boil them for 30 minutes, remove them to dry, and then vacuum-dry them at 50°C to a water content of less than 0.5%, then crush them according to common methods to obtain cocoa powder. Mix 6 kg of fructose, 1 kg of glucose, 1 kg of phenylalanine, 0.6 kg of leucine, 0.2 kg of alanine, 0.04 kg of lysine, 0.03 kg of valine, and 0.02 kg of arginine. Acid, 0.02 kg of isoleucine and 0.1 kg of lysine are mixed and crushed, then mixed into the cocoa powder obtained above, after fully mixing, airtightly heated at 110~112℃ for 30 minutes to obtain natural cocoa with strong aroma The main agent (1) 508.91 kg.

Embodiment 2

[0018] Example 2 Preparation method of natural cola main agent (2)

[0019] After 625 kg of fresh cocoa beans are washed, added to boiling water, boiled for 30 minutes, taken out to dry, and then vacuum dried at 50°C to a water content of less than 0.5%, and cocoa mass is prepared according to common methods. Mix and grind 3.0 kg of fructose, 1.0 kg of glucose, 1.2 kg of phenylalanine, 0.7 kg of leucine, and 0.3 kg of alanine, and then stir them into the cocoa liquor obtained above. After being thoroughly mixed, airtightly heated at 115-116°C for 25 minutes to obtain 631.2 kg of natural cocoa main agent (2) with strong aroma.

Embodiment 3

[0020] Example 3 Preparation method of natural cola main agent (3)

[0021] Wash 385 kg of fresh cocoa beans, add them to boiling water, boil for 30 minutes, remove and dry, and then vacuum dry at 50°C to a water content of less than 0.5%, and prepare cocoa powder according to common methods. After mixing and pulverizing 10 kg of fructose, 4 kg of glucose, 0.8 kg of phenylalanine, 0.4 kg of leucine, and 0.2 kg of alanine, stir them into the cocoa powder obtained above. After mixing, airtightly heat at 118-120°C for 20 minutes to obtain 400.4 kg of natural cocoa main agent (3) with strong aroma.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com