Digital accumulator battery

A battery pack and storage battery technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems that the terminal voltage will not be strictly consistent, the service life of the battery pack is short, and the floating charge voltage of the battery is offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

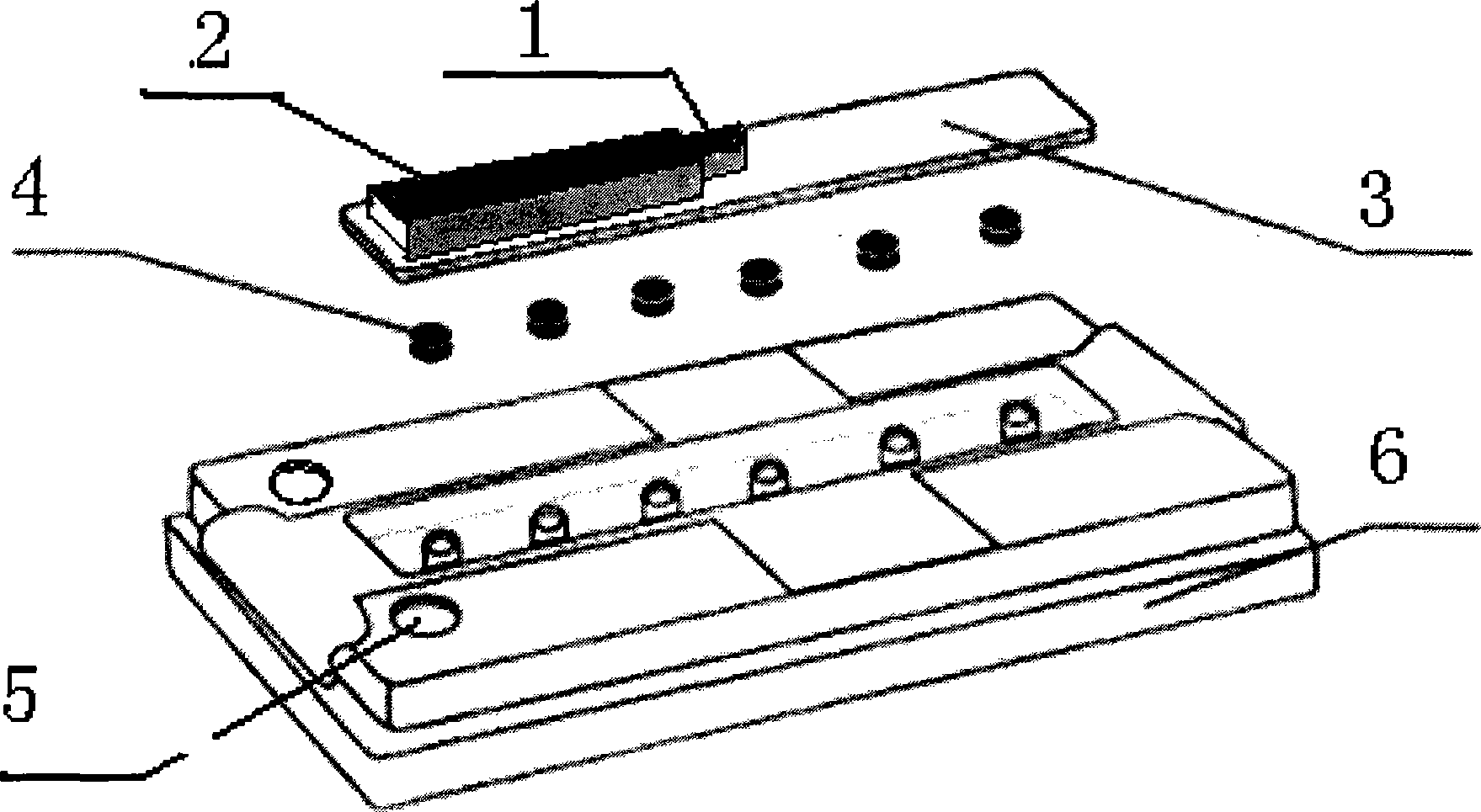

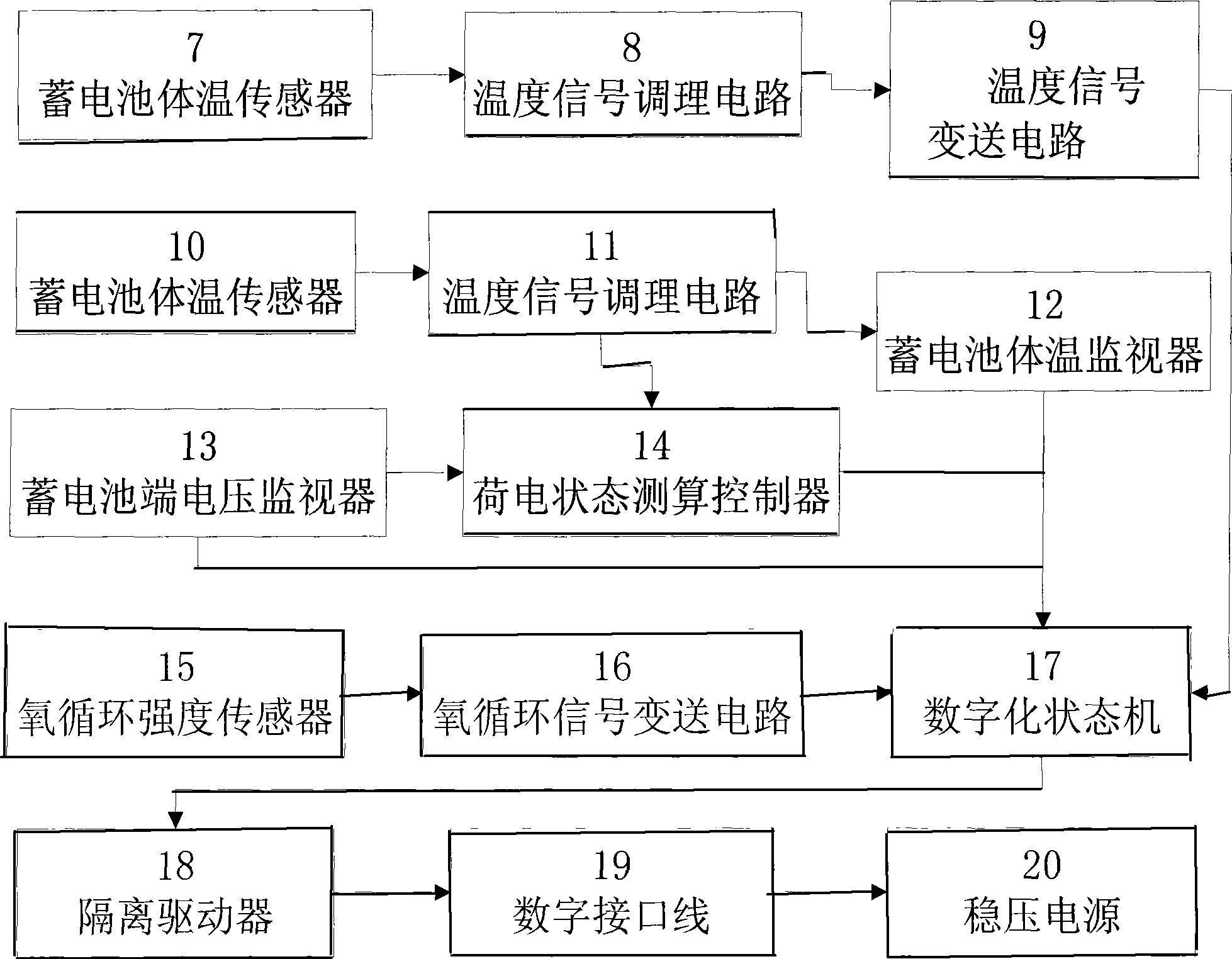

[0035] Please see attached Figure three . According to attached Figure three Make a measurement and control module with a volume of 20 by 40 by 4 mm, and encapsulate it in a partially detachable shell of the battery pack. Attached below Figure three The details of this embodiment will be described.

[0036] The battery body temperature sensors R17 and R23 are fixed close to the inner wall of the packaging cavity of the integrated measurement and control module, and then packaged with a heat insulation layer and thermally isolated from the outer wall.

[0037] The temperature signal conditioning circuit is composed of constant voltage sources U1, R8, constant current sources Q1, R2, C2, and correction resistors R16 and R19. The temperature signal transmission circuit composed of Q3, R12, and C8 reads the value of the temperature signal conditioning circuit and feeds it to the digital state machine. In the self-adaptive program-controlled constant current integral chargi...

Embodiment 2

[0050] Please see attached Figure four . This example does not need the support of the microcontroller to realize the adaptive program-controlled constant current integral charging method, which is more suitable for low-cost applications, such as electric bicycle battery packs. According to attached Figure four Make a measurement and control module with a volume of 20 by 40 by 4 mm, and encapsulate it in a partially detachable housing of the battery pack. Attached below Figure four The details of this embodiment will be described.

[0051] The battery body temperature sensors R17 and R23 are fixed close to the inner wall of the packaging cavity of the integrated measurement and control module, and then packaged with a heat insulation layer and thermally isolated from the outer wall.

[0052] The temperature signal conditioning circuit is composed of: constant voltage source U1, R8, constant current source Q1, R2, C2, and correction resistor R16, R19. It is used to corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com