UV optical cable

An optical cable and optical fiber technology, applied in the field of UV optical cable, can solve the problems of large diameter of optical cable and inconvenient connection, and achieve the effect of fast production speed, convenient and fast welding, and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

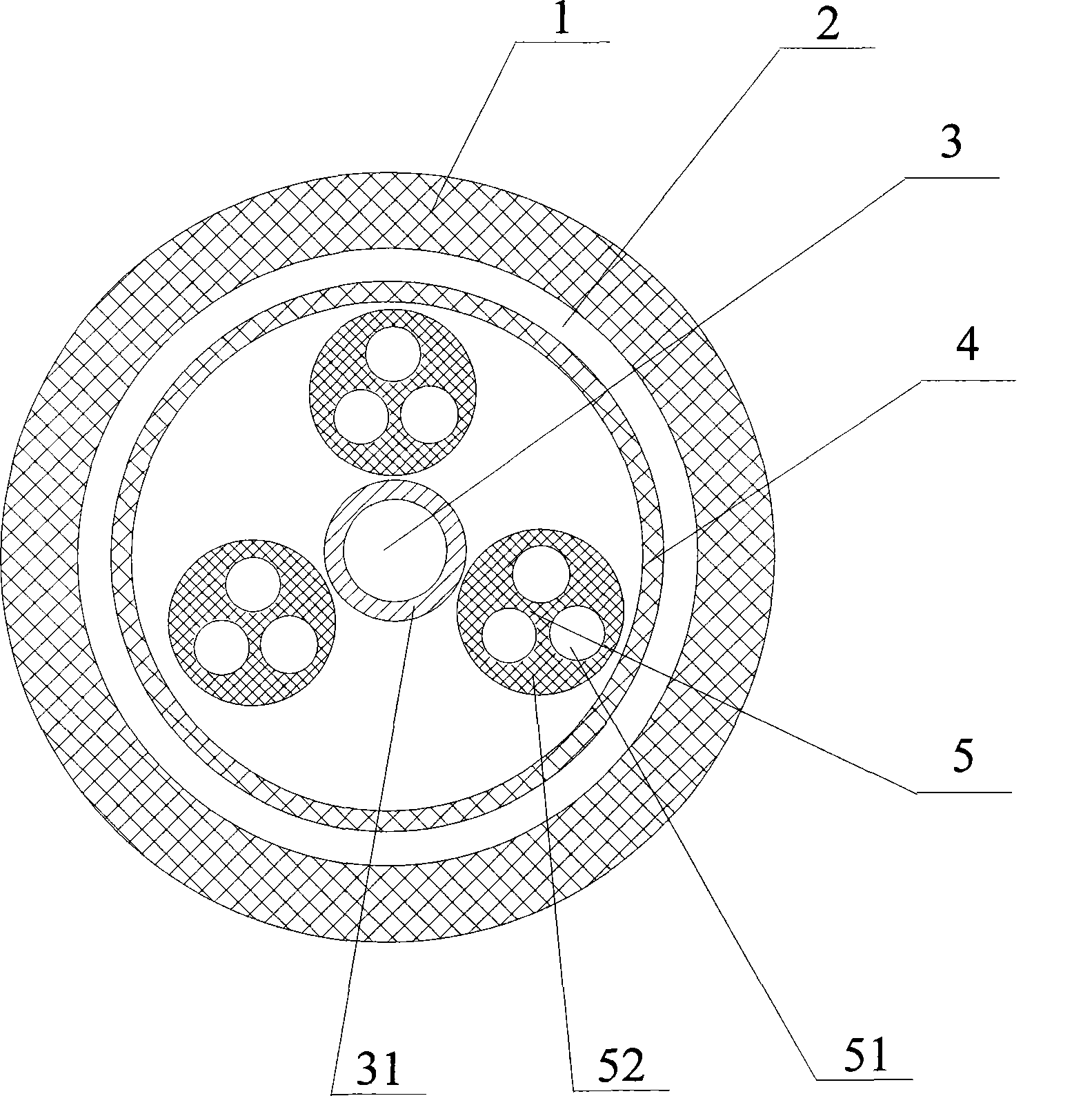

Embodiment 1

[0026] Such as figure 1 As shown, the present invention includes a central strength member 3 and a cable core composed of three optical fiber bundles 5 twisted around the central strength member 3, and the outer circumferential surface of the cable core is coated with a water blocking tape 4 and an auxiliary strength member in turn. 2 and sheath 1. The cross-section of the optical fiber bundle 5 is circular, and is formed by fixing three optical fibers 51 in bundles at intervals inside the ultraviolet curable resin 52. The central reinforcing member 3 is steel wire or FRP and is wrapped with a water-blocking yarn 31 for water-blocking. Belt 4 is single-sided water-blocking tape, double-sided water-blocking tape, laminated single-sided water-blocking tape or laminated double-sided water-blocking tape, and the auxiliary reinforcement 2 is one of glass fiber and aramid fiber, or the above-mentioned A mixture of two fibers, the sheath 1 is polyethylene, polyvinyl chloride, polyur...

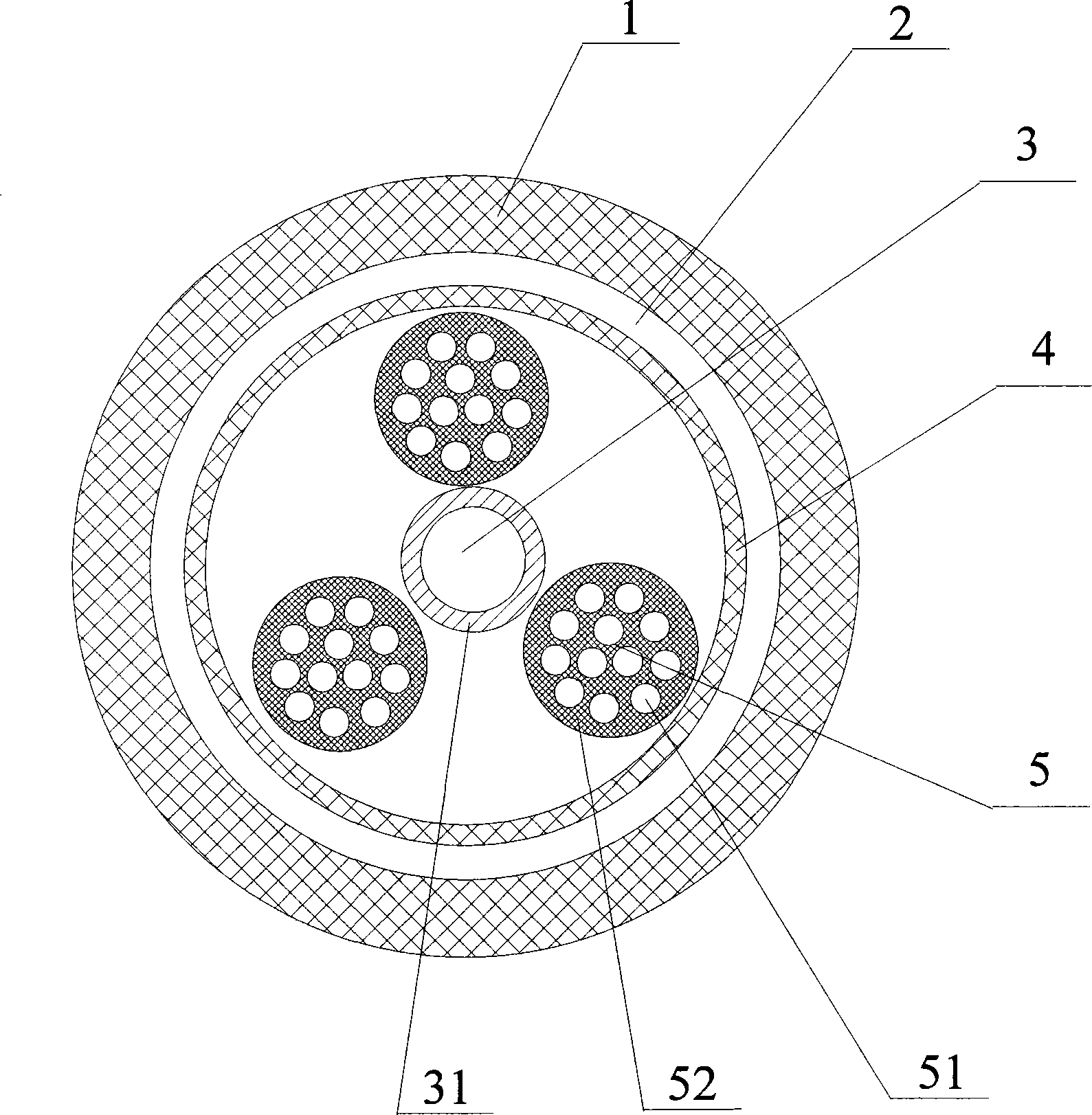

Embodiment 2

[0028] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the number of optical fibers 51 in the optical fiber bundle 5 is twelve.

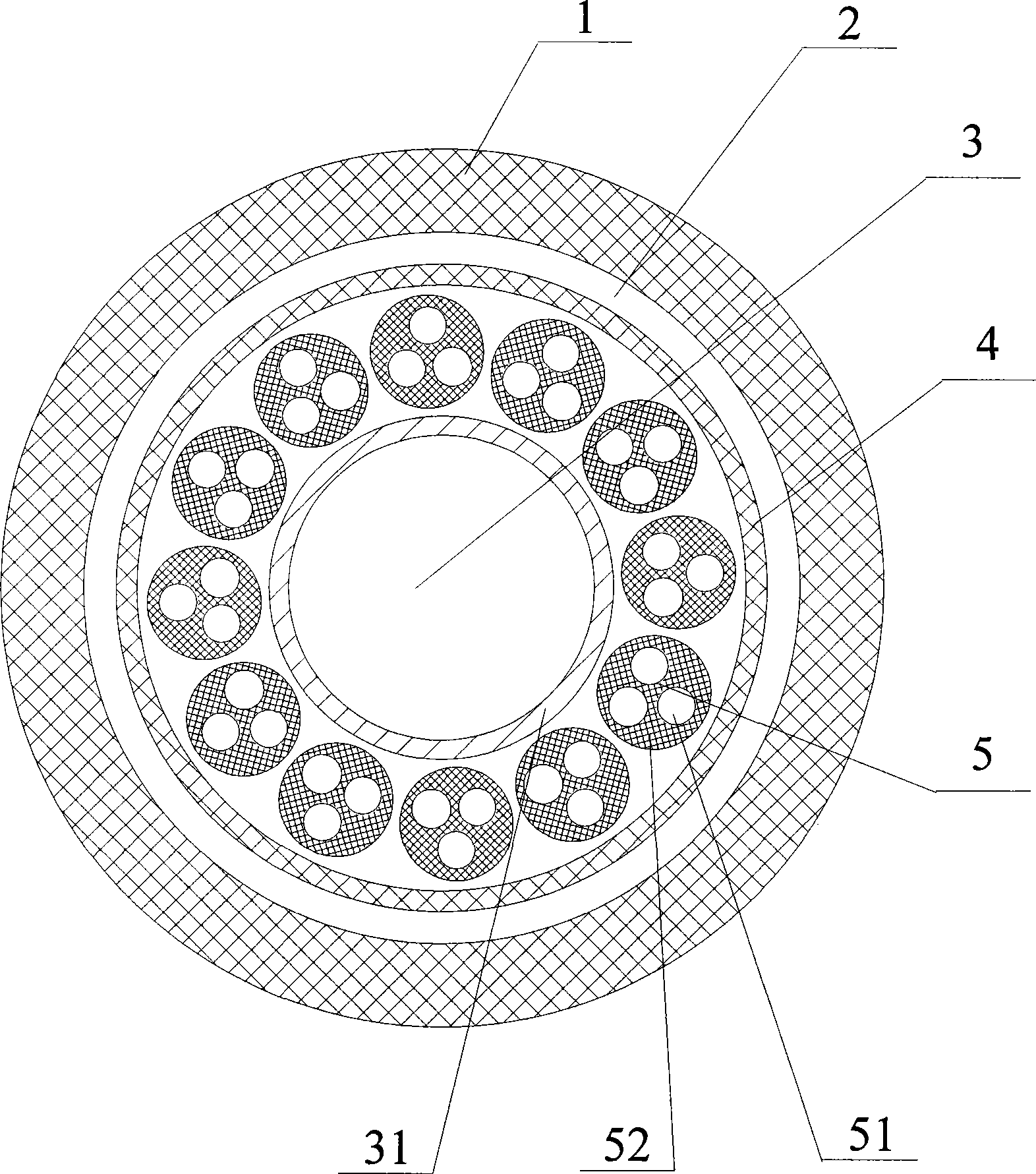

Embodiment 3

[0030] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the number of optical fiber bundles 5 is twelve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com