Device energy-wasting type multi-ribbed composite wallboard

A composite wall and dense rib technology, which is applied to walls, building components, and earthquake resistance, can solve the problem that fillers cannot meet the selection requirements of building materials, limit the use of energy-consuming components of composite wall panels, and take too little consideration of changes in the seismic performance of structures, etc. problem, to achieve the effect of clear structural force transmission route, convenient post-earthquake maintenance, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

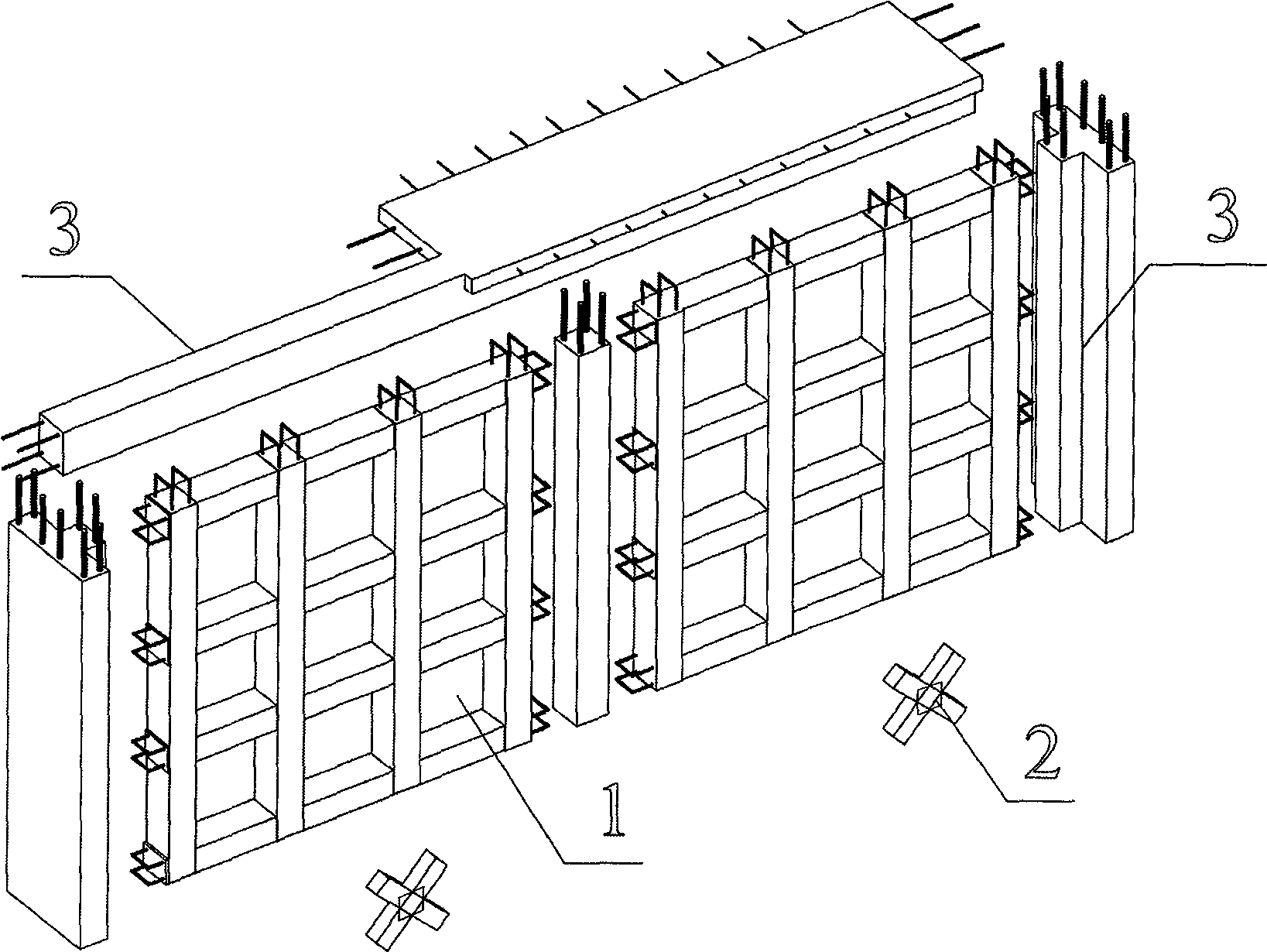

[0032] Embodiments of the invention will be described in further detail below in conjunction with the accompanying drawings.

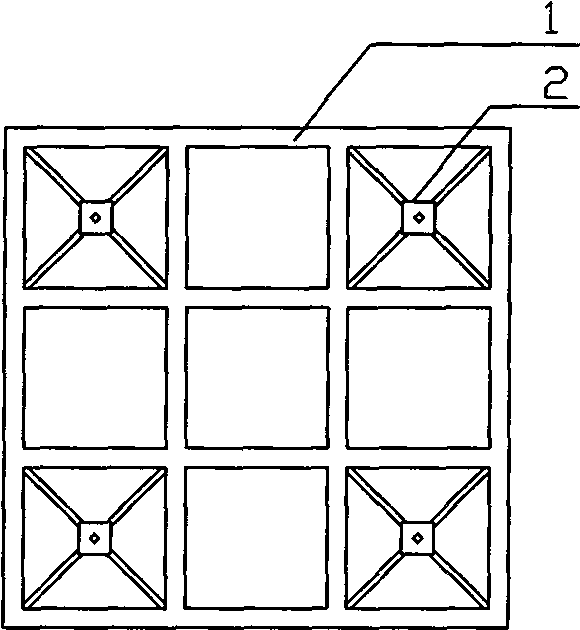

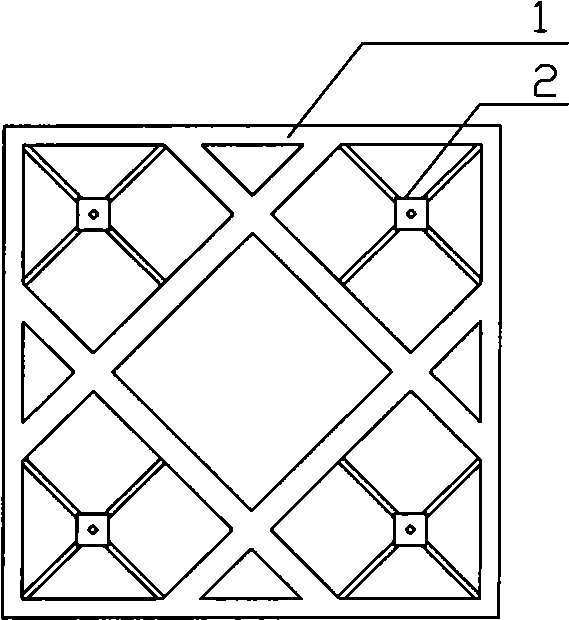

[0033] A densely ribbed composite wall used in a densely ribbed structure system, including a frame 3 composed of shaped steel, shaped steel concrete reinforced concrete beams, and columns. A number of sash cells are divided to form a grid cavity 1, and damping devices 2 are filled in the grid cavity 1 according to the bearing capacity of reinforced concrete beams and columns. The damping device 2 includes, for example, elastic-plastic materials, several miniaturized dampers, and the like. The filled damping device 2 adopts miniaturized energy-dissipating supports, mild steel dampers, friction dampers, viscoelastic dampers or viscous dampers, which are welded to the angle steel blocks or steel plates embedded in the grid cavity 1 or bolted together. According to the requirements of the bearing capacity, the damping device 2 is selected to be filled i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com