Solvent-resistance polystyrene ternary alloy material for refrigerator inner liner plates and preparation method and application thereof

A polystyrene and refrigerator liner technology, which is applied in applications, household refrigeration devices, chemical instruments and methods, etc., can solve the problems of unstable grafting rate, unstable compatibility, and increased production costs of grafted materials. Achieve good hot-melt processing performance, excellent solvent resistance, and rapid delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

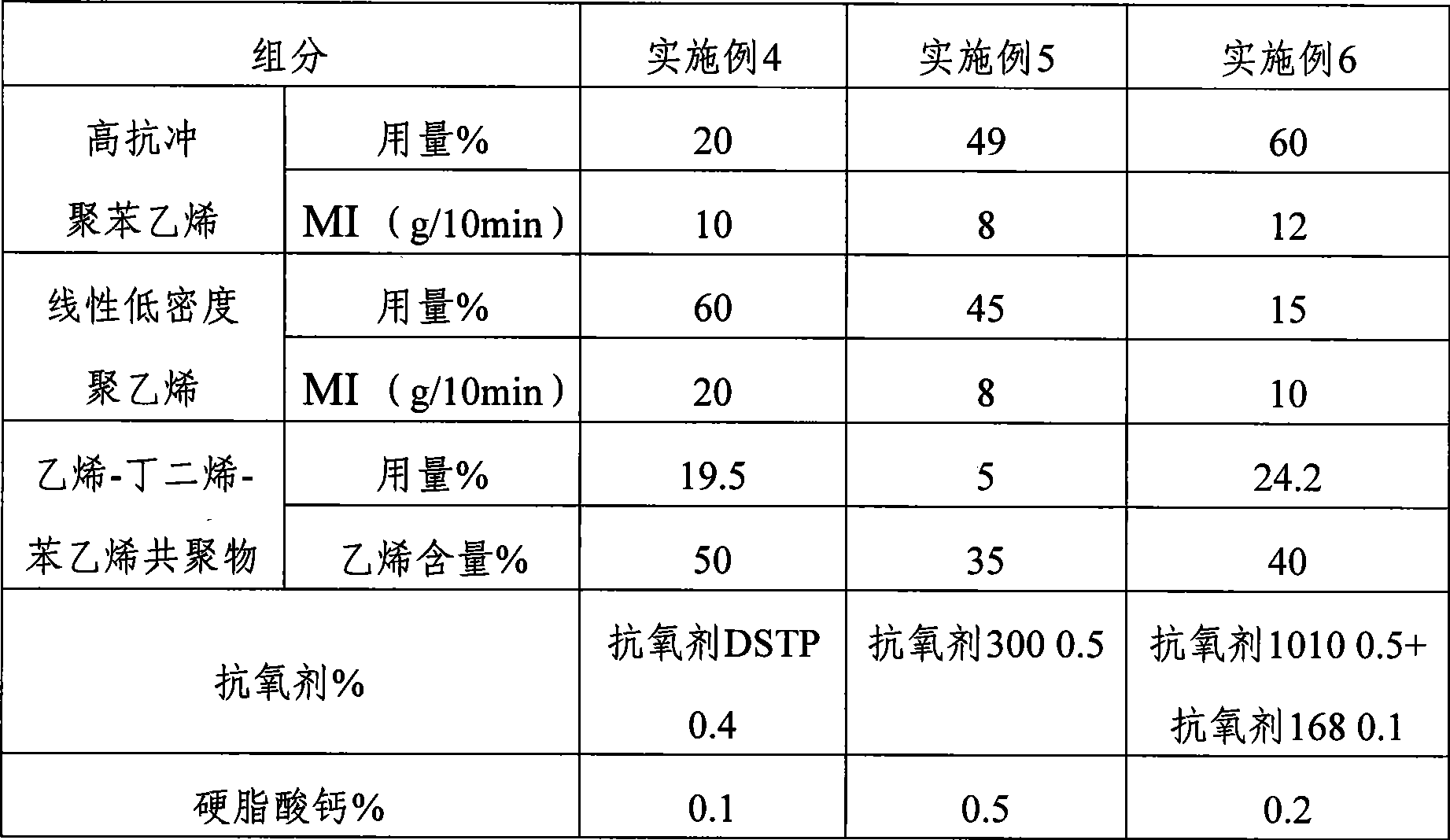

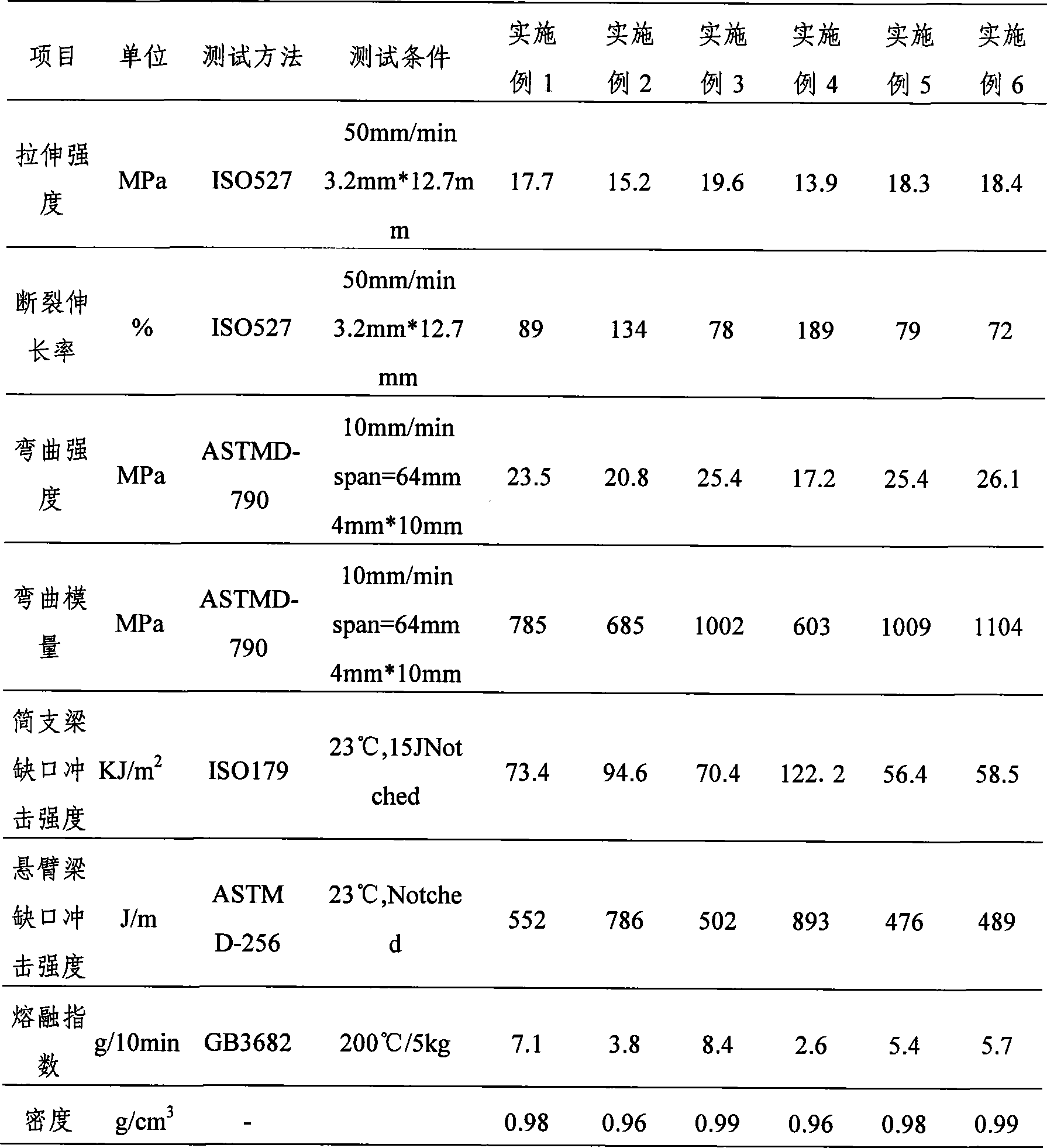

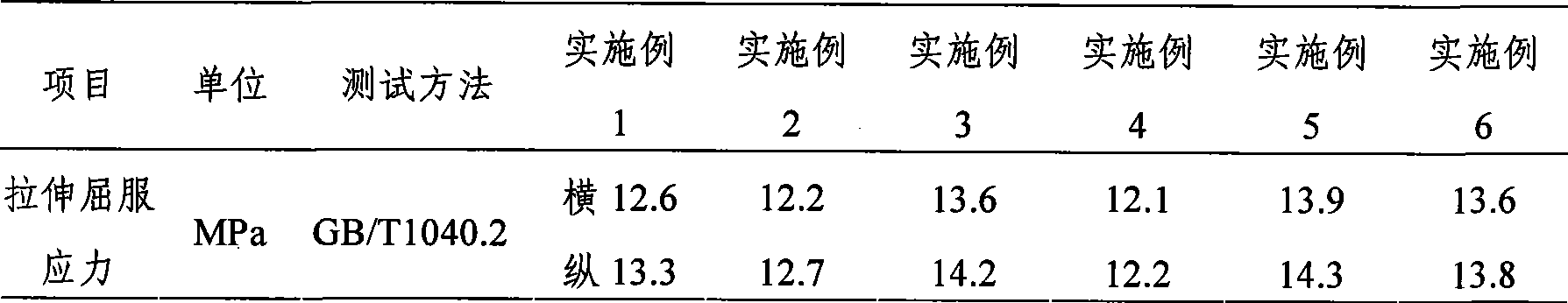

Examples

Embodiment 1

[0035] The solvent-resistant polystyrene ternary alloy material for the refrigerator liner plate of the present embodiment is composed of 65% high-impact polystyrene, 20% linear low-density polyethylene, and 14% ethylene-butadiene-styrene copolymer phase Composite agent, 0.5% antioxidant 1010 and 0.5% calcium stearate.

[0036] Among them, high-impact polystyrene is 495F produced by BASF, MI is 12g / 10min (200℃ / 5kg), Izod impact strength is 110J / m, linear low-density polyethylene MI is 9g / 10min (190℃ / 5kg), ethylene-butadiene-styrene copolymer is a block copolymer, wherein the ethylene content is 25%.

[0037] The solvent-resistant polystyrene ternary alloy material used for the refrigerator liner plate in this embodiment is firstly added to a high-speed mixer in proportion to each component and mixed at a high speed for 3 minutes, and then subjected to twin-screw extrusion at 200±10°C. Extruded out of the machine, the strips are cooled in the water tank, and then cut into all...

Embodiment 2

[0041] The solvent-resistant polystyrene ternary alloy material for the refrigerator liner plate of the present embodiment is composed of 35% high-impact polystyrene, 40% linear low-density polyethylene, and 24.3% ethylene-butadiene-styrene copolymer phase Composite agent, 0.1% antioxidant 168 and 0.6% calcium stearate.

[0042] Among them, the high-impact polystyrene is 1300 produced by Dow in the United States, the MI is 7.5g / 10min (200°C / 5kg), the Izod impact strength is 100J / m, and the MI of linear low-density polyethylene is 6g / 10min (190°C). ℃ / 5kg), ethylene-butadiene-styrene copolymer is a block copolymer, wherein the ethylene content is 35%.

[0043] The solvent-resistant polystyrene ternary alloy material for the refrigerator liner plate in this embodiment is firstly added to the high-speed mixer in proportion to the high-speed mixing for 2 minutes, and then subjected to twin-screw extrusion at 180±10°C. Extruded out of the machine, the strips are cooled in the water...

Embodiment 3

[0045] The solvent-resistant polystyrene ternary alloy material for the refrigerator liner plate of the present embodiment is composed of 55% high-impact polystyrene, 35% linear low-density polyethylene, and 9.5% ethylene-butadiene-styrene copolymer phase Composite agent, 0.2% antioxidant 1076 and 0.3% calcium stearate.

[0046] Among them, the high-impact polystyrene is 476L produced by BASF, the MI is 4g / 10min (200℃ / 5kg), the Izod impact strength is 80J / m, and the MI of linear low-density polyethylene is 2g / 10min (190℃ / 5kg). ), ethylene-butadiene-styrene copolymer is a block copolymer, wherein the ethylene content is 30%.

[0047] The solvent-resistant polystyrene ternary alloy material for the refrigerator liner plate in this embodiment is firstly added to the high-speed mixer in proportion to the high-speed mixing for 1 minute, and then extruded by twin-screw at 210±10°C. Extruded out of the machine, the strips are cooled in the water tank, and then cut into alloy product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com