Controlled polymer/inorganic compound hollow microsphere and method for preparing same

A technology of hollow microspheres and inorganic composites, applied in the field of composite materials and functional materials, can solve the problems of poor compatibility of organic matrix, decline of overall performance, poor mechanical properties, etc., and achieve good compatibility, high mechanical strength and stable size good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

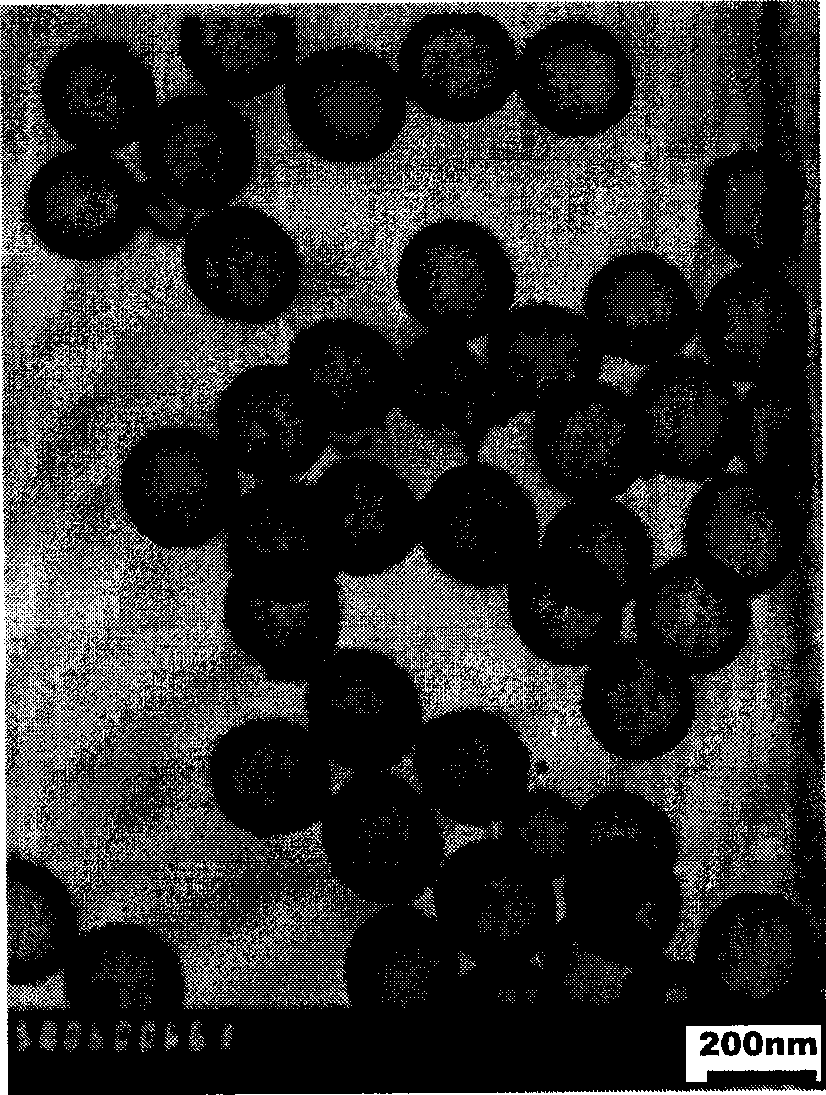

Image

Examples

Embodiment 1

[0037] The ratio of raw materials used is as follows:

[0038] 2 parts of hollow silica microspheres (mass number)

[0039] KH-550 1 part (mass number)

[0040] 4-glycidyl ether-2,2,6,6-tetramethylpyridine-1-oxygen (GTEMPO) 0.5 parts (mass number)

[0041] 1 part of styrene (mass number)

[0042] 2g of hollow silica microspheres were ultrasonically dispersed with ethanol, added to a reaction vessel, ventilated with nitrogen, condensed and refluxed, controlled at a temperature of 80°C, added 1g of KH-550, stirred by magnetic force, reacted for 12 hours, cooled, centrifuged, and washed several times with ethanol . Then use ethanol to ultrasonically disperse, add 0.5g GTEMPO, under nitrogen atmosphere, stir at room temperature for 36 hours, centrifuge, and wash repeatedly with ethanol several times to ensure that all unreacted GTEMPO is removed. Hollow silica microspheres connected with nitroxide radicals were dispersed with toluene, under nitrogen protection, 1 g of styrene ...

Embodiment 2

[0044] The ratio of raw materials used is as follows:

[0045] 2 parts of hollow silica microspheres (mass number)

[0046] KH-550 1 part (mass number)

[0047] GTEMPO 0.5 part (mass number)

[0048]Azobisisobutyronitrile (AIBN) 0.1 part (mass number)

[0049] 1 part of styrene (mass number)

[0050] 2g of hollow silica microspheres were ultrasonically dispersed with ethanol, added to a reaction vessel, ventilated with nitrogen, condensed and refluxed, controlled at a temperature of 80°C, added 1g of KH-550, stirred by magnetic force, reacted for 12 hours, cooled, centrifuged, and washed several times with ethanol . Then use ethanol to ultrasonically disperse, add 0.5g GTEMPO, under nitrogen atmosphere, stir at room temperature for 36 hours, centrifuge, and wash repeatedly with ethanol several times to ensure that all unreacted GTEMPO is removed. The hollow silica microspheres connected with nitroxide radicals were dispersed with toluene, under the protection of nitrogen,...

Embodiment 3

[0052] The ratio of raw materials used is as follows:

[0053] 2 parts of hollow silica microspheres (mass number)

[0054] KH-550 1 part (mass number)

[0055] GTEMPO 0.5 part (mass number)

[0056] Azobisisobutyronitrile (AIBN) 0.1 part (mass number)

[0057] 2 parts of styrene (mass number)

[0058] 2g of hollow silica microspheres were ultrasonically dispersed with ethanol, added to a reaction vessel, ventilated with nitrogen, condensed and refluxed, controlled at a temperature of 80°C, added 1g of KH-550, stirred by magnetic force, reacted for 12 hours, cooled, centrifuged, and washed several times with ethanol . Then use ethanol to ultrasonically disperse, add 0.5g GTEMPO, under nitrogen atmosphere, stir at room temperature for 36 hours, centrifuge, and wash repeatedly with ethanol several times to ensure that all unreacted GTEMPO is removed. The hollow silica microspheres connected with nitroxide radicals were dispersed with toluene, under the protection of nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com