Manufacturing methods of mesoporous carbon structure with spray drying or spray pyrolysis and composition thereof

A technology of spray pyrolysis and pyrolysis, which is applied in the fields of carbon compounds, chemical instruments and methods, catalyst activation/preparation, etc. It can solve the problems of difficulty in preparing templates, inability to obtain pore size and shape, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

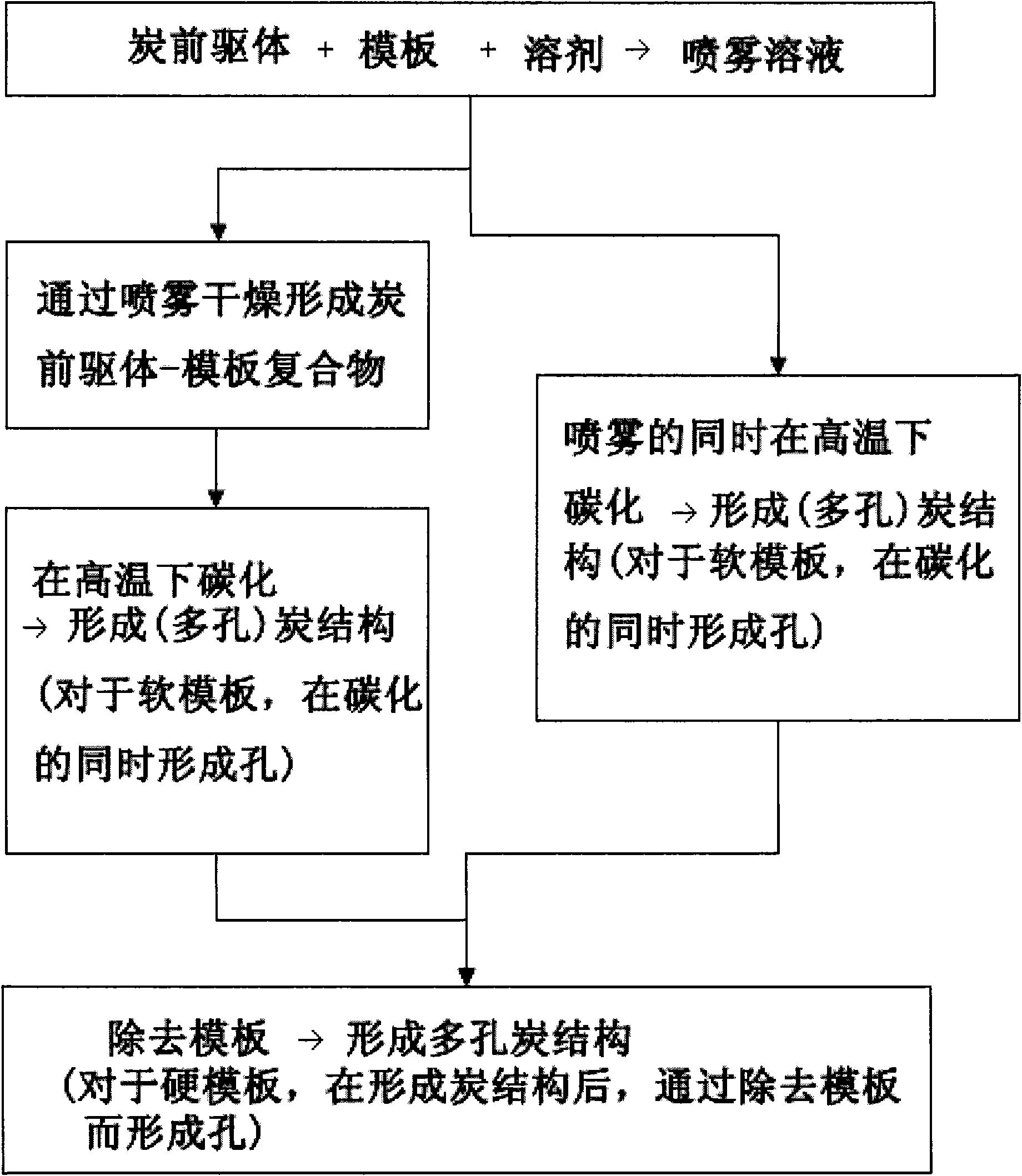

Method used

Image

Examples

Embodiment 1

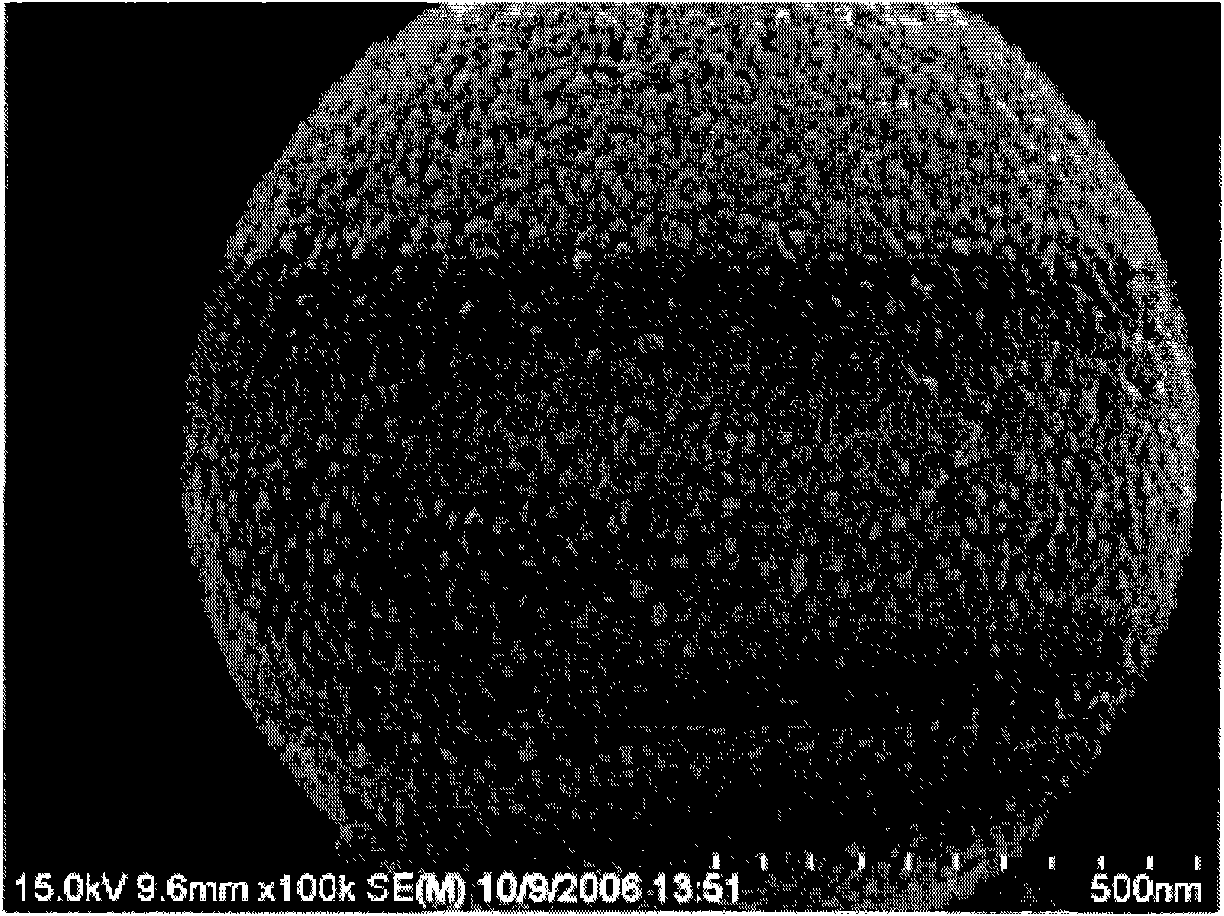

[0054] 5 g of sucrose and 8 g of silica particles (Ludox AS-40) having an average particle diameter of about 10 nm were dissolved in 80 ml of water at room temperature, and then 4 ml of concentrated sulfuric acid was slowly added thereto. The solution was stirred for 12 hours, and then nitrogen gas at a temperature of 150° C. was blown into the solution using a spray dryer while spraying out fine droplets of the solution, thereby preparing spherical particles composed of a mixture of sugar polymer and Ludox particles. The spherical particles were carbonized in a pyrolysis furnace at 800°C for 1 hour under a nitrogen atmosphere, and then the silica was removed with HF. The remaining particles were washed with water and finally dried under vacuum. The synthesized porous carbon structure has a 760m 2 / g BET surface area and 0.908cm 3 / g single point pore volume (singlepoint pore volume). The SEM pictures of the prepared porous carbon structure are as follows: figure 2 shown....

Embodiment 2

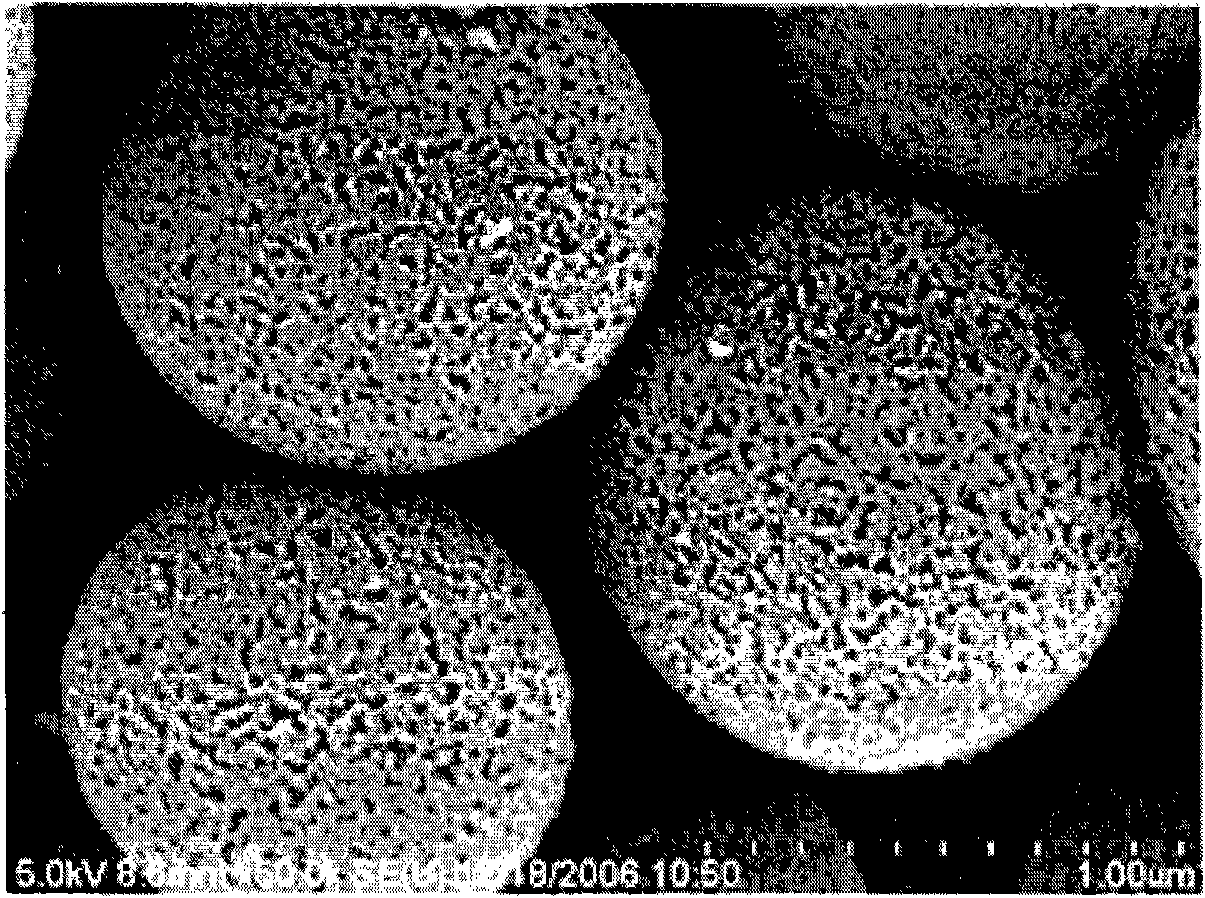

[0056] A spherical carbon structure was prepared in the same manner as in Example 1, except that 4.8 g of sodium sulfate (instead of silica particles) and 8 g of sucrose were used to prepare the spray solution, and water was used instead of HF to remove metal salts. The synthesized porous carbon structure has a 1340m 2 / g BET surface area and 2.9cm 3 / g single-point pore volume. image 3 The SEM photographs of the prepared porous carbon structures are shown in .

Embodiment 3

[0058] A 50-wt% aqueous solution of polyacrylamide (Aldrich) with a weight average molecular weight of 50g of 10,000, a 40-wt% aqueous solution of 25g glyoxal (Aldrich), 25g of Na 2 SO 4 , 10g of FeCl 3 and 40 g of distilled water were mixed with each other, and the mixture was stirred at 60° C. for 3 hours to prepare a spray solution. The solution was spray dried at 180°C to obtain 61 g of polymer complex. 10 g of the polymer complex was carbonized at 600° C., washed 3 times with distilled water, and then dried to obtain 4.3 g of a charcoal composition. The BET surface area of the porous carbon structure thus prepared is 738m 2 / g, and Figure 4 The SEM photograph of the porous carbon structure is shown in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com