Zinc oxide based semiconductor luminous component and manufacturing method thereof

A light-emitting component, zinc oxide technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficulty in producing high-quality P-type zinc oxide, inability to produce light-emitting diodes, stagnant technological development, etc. Effects of interface quality and uniformity, low material growth temperature, and low material defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

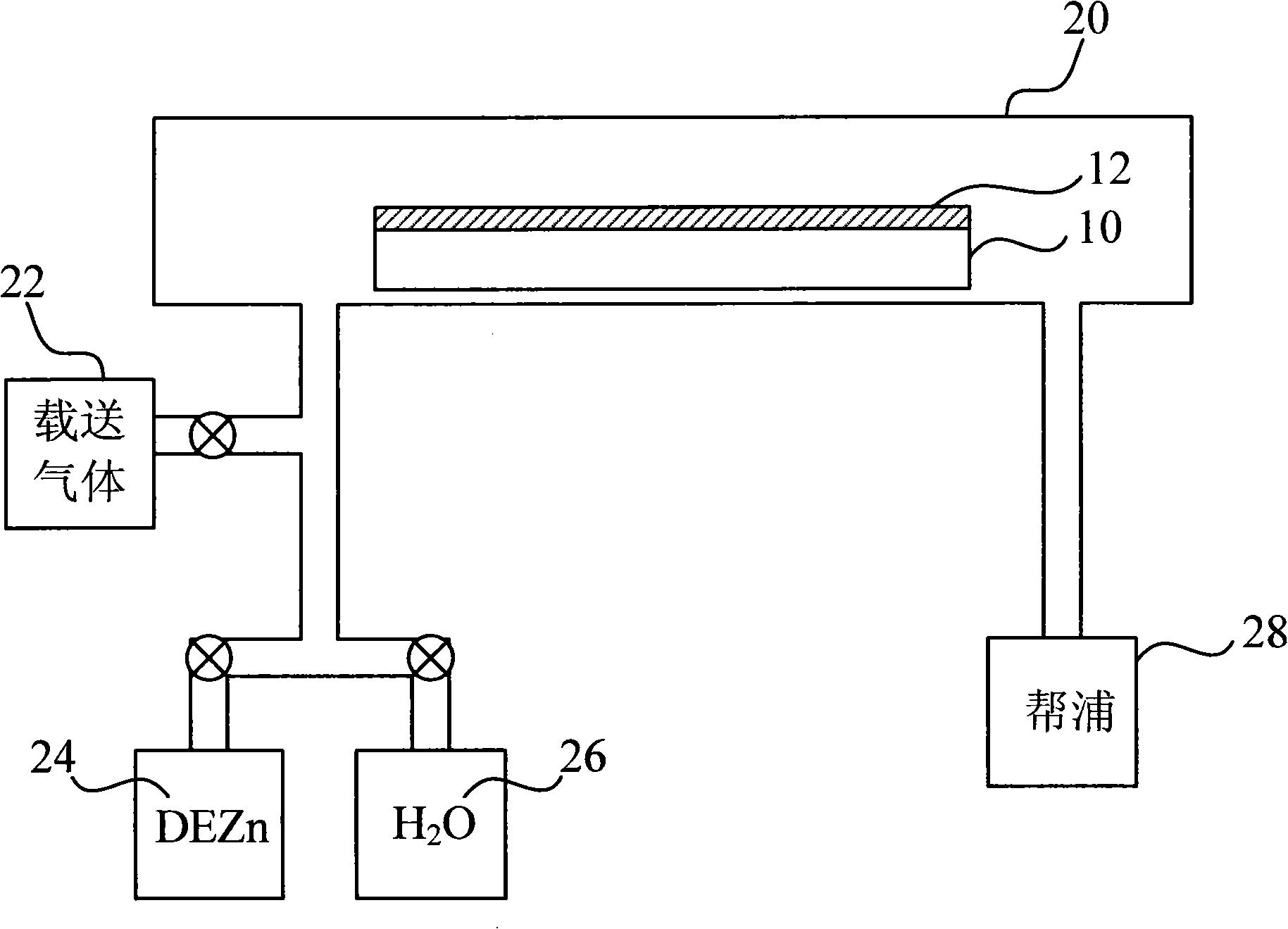

[0024] see figure 1 , figure 1 is a schematic diagram of a manufacturing method according to a preferred embodiment of the present invention. The manufacturing method according to the preferred embodiment of the present invention utilizes a process based on atomic layer deposition to manufacture zinc oxide-based semiconductor light-emitting components. Here, the zinc oxide-based semiconductor light-emitting component means that it contains a zinc oxide layer, Mg x Zn 1-x O layer, Be y Zn 1-y O layer or other compound layers containing zinc oxide, but not limited thereto.

[0025] Such as figure 1 As shown, first, a substrate 10 is prepared, and the substrate 10 is placed in a reaction chamber 20 designed to perform an atomic layer deposition process. In this embodiment, substrate 10 can be sapphire substrate, silicon substrate, SiC substrate, GaN substrate, AlGaN substrate, InGaN substrate, ZnO substrate, YSZ (yttria-stabilized zirconia) substrate, ScAlMgO 4 Substrate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com