Acrylaldehyde preparation method by glycerin dehydration under inert gas dilution

An inert gas and acrolein technology, applied in chemical instruments and methods, carbon-based compound preparation, organic compound preparation, etc., can solve the problems of low acrolein yield, low stability, high energy consumption, etc., and achieve space-time yield High, high stability, selectivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Load the macroporous γ-alumina catalyst into the fixed-bed continuous flow reaction device, and use the pump to continuously send the aqueous solution of glycerol as the raw material into the reactor. The molar ratio with nitrogen is 1:10, the reaction pressure is normal pressure, and the liquid hourly space velocity is 1.7h -1 , the reaction results are shown in Table 1.

[0020] Table 1

[0021]

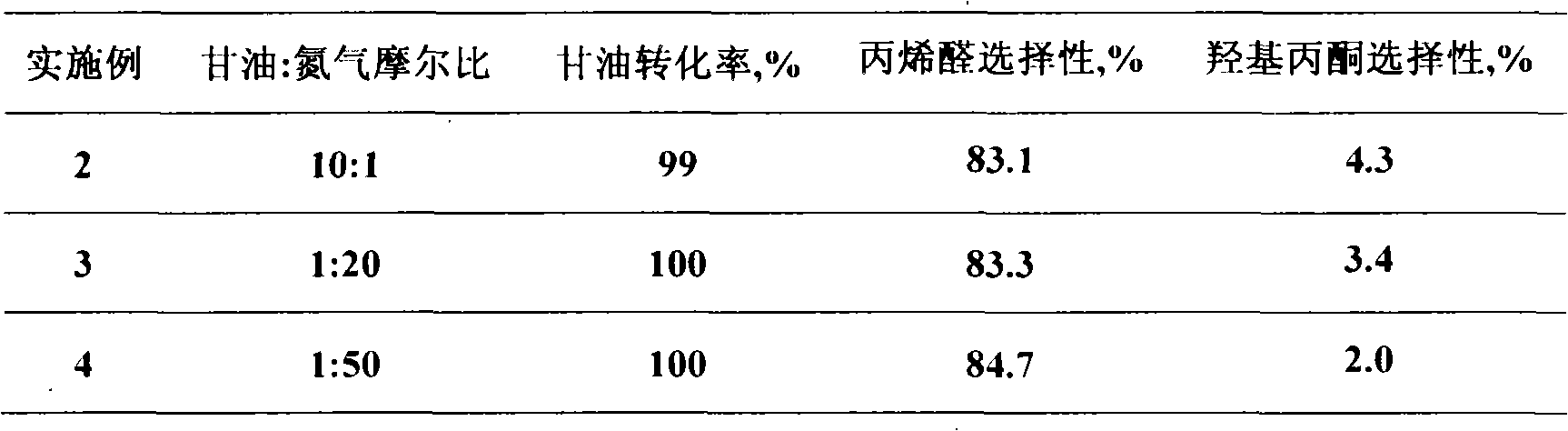

Embodiment 2-4

[0023] The catalyst and reaction conditions were the same as those in Example 1, and the glycerin dehydration reaction was carried out with different molar ratios of nitrogen and glycerol. The results are shown in Table 2.

[0024] Table 2

[0025]

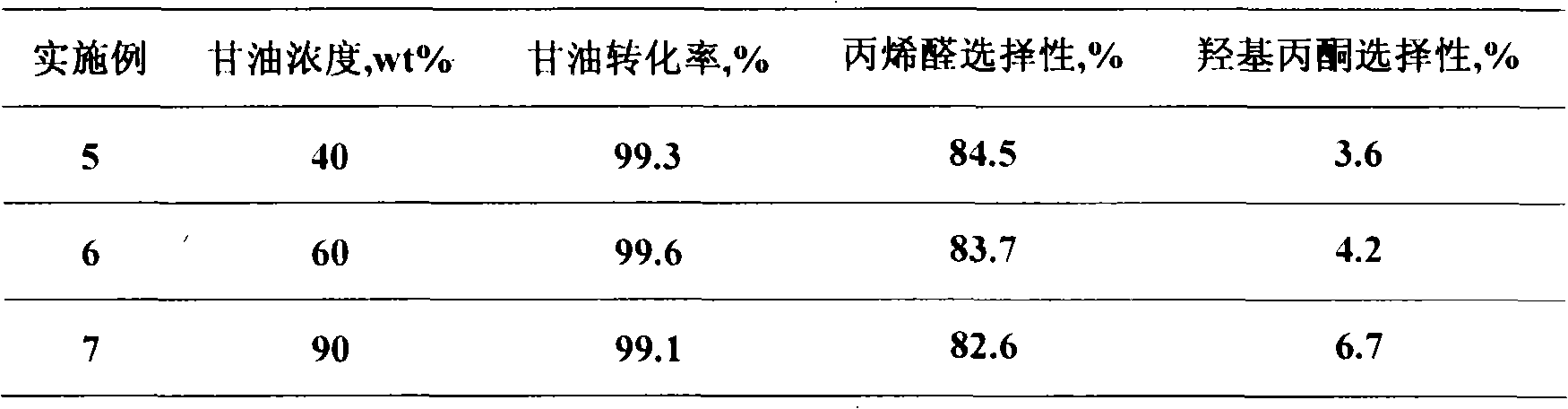

Embodiment 5-7

[0027] Catalyst and reaction condition are the same as embodiment 1, change glycerin concentration in the aqueous solution, reaction result is shown in table 3.

[0028] table 3

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com