Low roller driving type sander

A driving type sanding machine technology, which is applied in belt grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of large torque, plate pause, plate clamping, etc., and achieve compact equipment layout, reduce pause, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

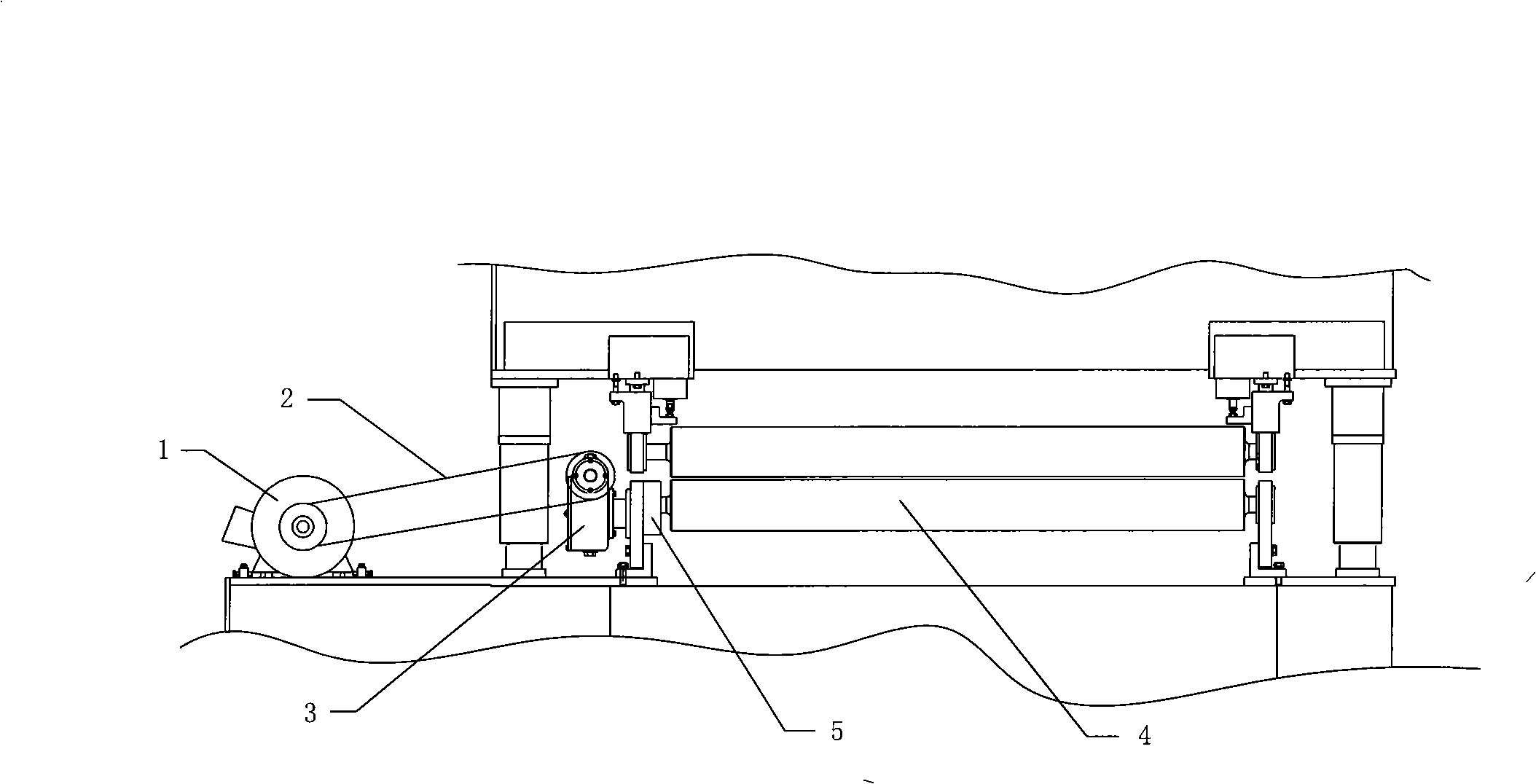

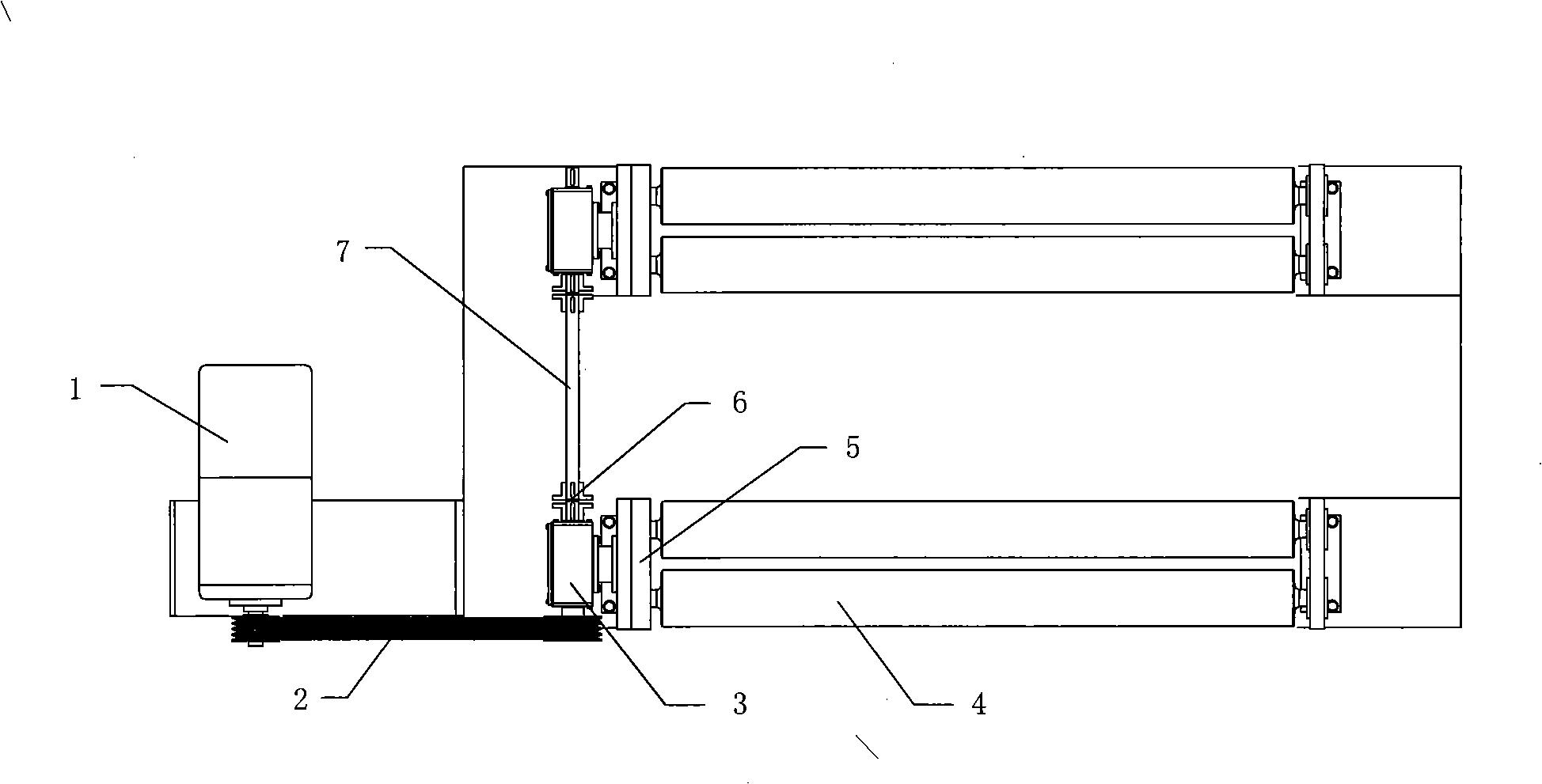

[0020] Such as figure 1 , figure 2 As shown, a lower roller driven sander includes a driving device, a transmission part, a reducer and a rubber-coated transport roller set, the drive device is connected to the reducer through a transmission part, and the rubber-coated transport roller set includes Gear box 5 and at least two rubber-covered transport rollers 4, one side of the gear box 5 is connected with the reducer, and the other side of the gear box 5 is connected with two rubber-covered transport rollers 4, the rubber-covered transport roller kit has at least two sets , the gear box 5 of each rubber-coated transport roller set is equipped with a shaft coupling, and a transmission shaft 7 is additionally installed between the shaft couplings.

[0021] According to a preferred embodiment of the present invention, the speed reducer is a worm gear speed reducer 3, which is directly connected to the intermediate gear of the rubber-covered transport roller 4, and the coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com