Welding structure and method of target and backing plate

A welding method and welding structure technology, which is applied in welding equipment, non-electric welding equipment, metal material coating technology, etc., can solve the problems that the atoms on the metal contact surface cannot be effectively diffused, and the joint strength cannot meet the requirements, so as to achieve the bonding strength Effect of improving, improving efficiency, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

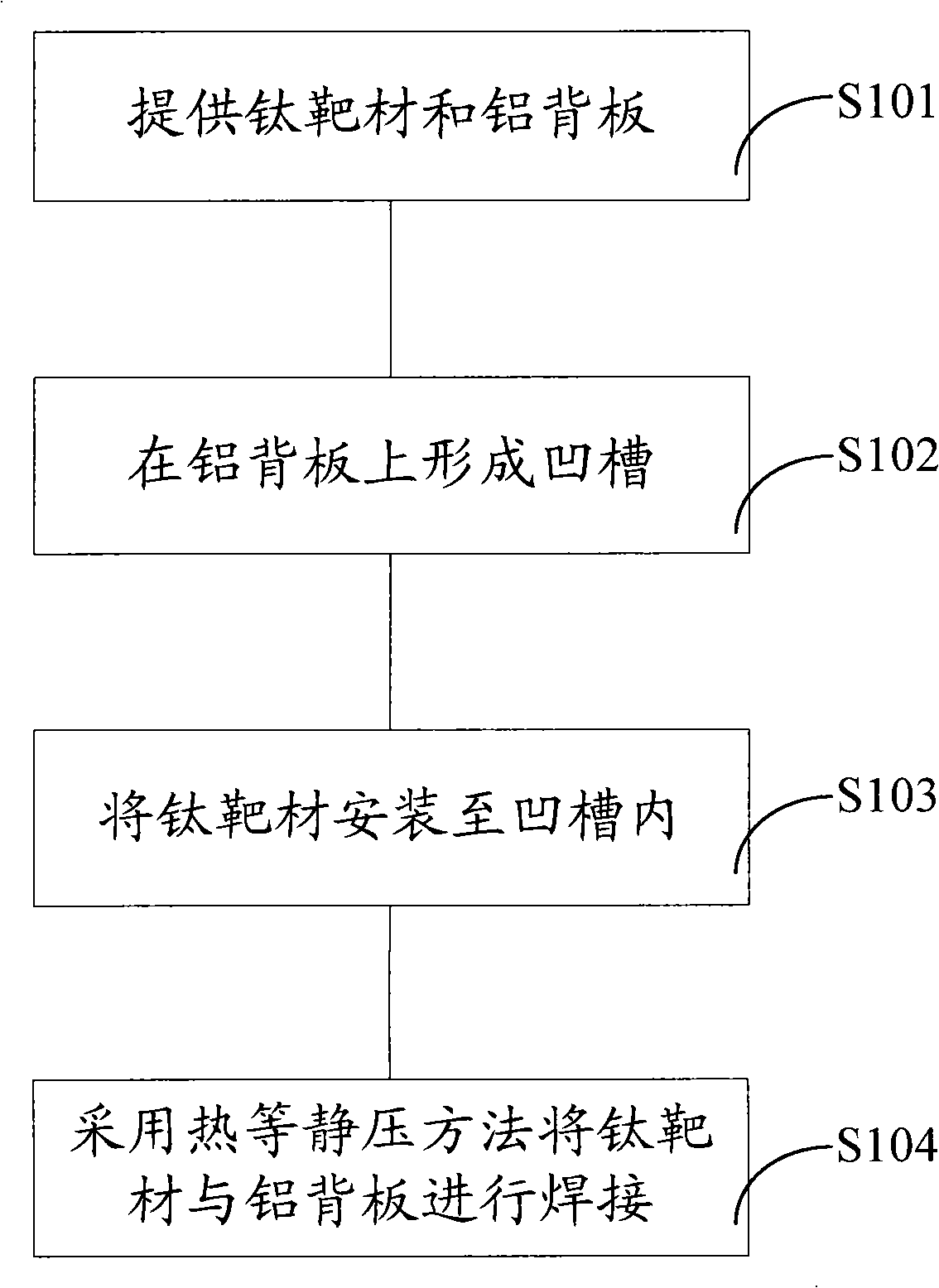

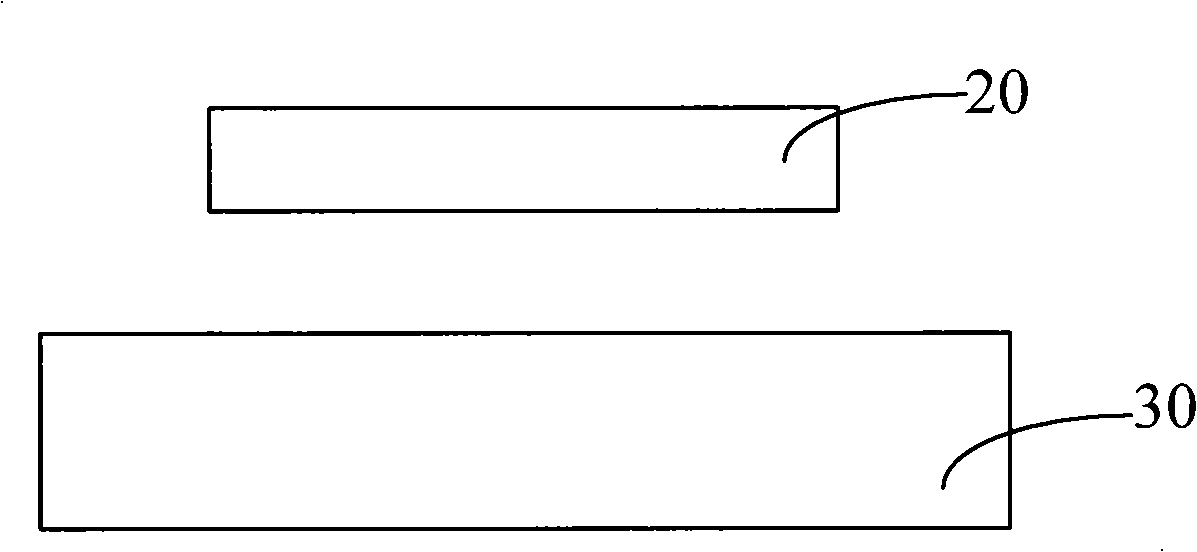

[0013] figure 1 It is a flow chart of a specific embodiment for making the welding structure of the target and the back plate according to the present invention. Such as figure 1 As shown, step S101 is performed to provide a titanium target and an aluminum back plate;

[0014] The titanium target is high-purity titanium (4N5) or ceramic sputtered titanium (5N).

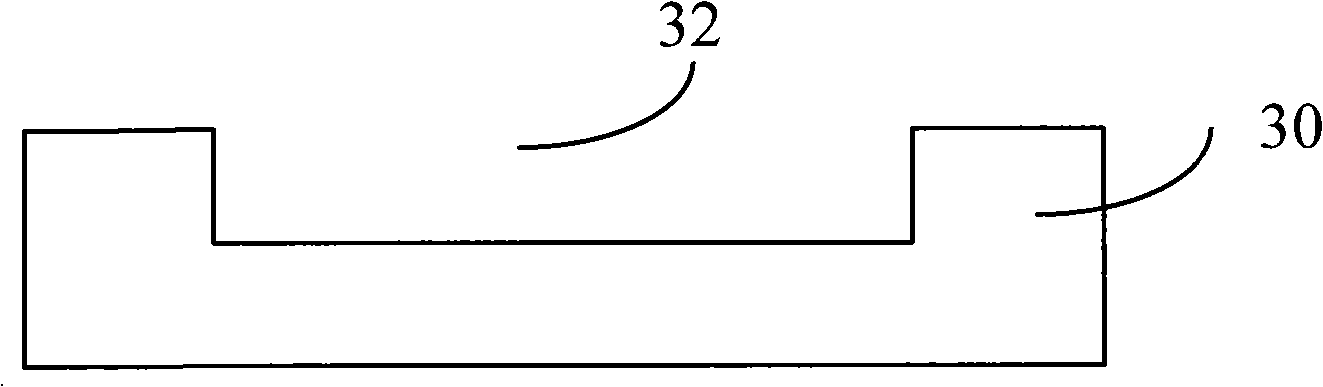

[0015] Execute step S102 to form grooves on the aluminum backplane;

[0016] The step of forming the groove may be: spin-coating a photoresist layer on the aluminum back plate; defining a groove pattern on the photoresist layer through a photolithography process; using the photoresist layer as a mask, Etch the aluminum backplate to form grooves with the same size as the titanium target.

[0017] Execute step S103 to install the titanium target into the groove;

[0018] Before putting the titanium target into the groove, it also includes: roughening the surface of the aluminum back plate; cleaning the titanium tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com