Rotating anode electrostatic precipitator

An electrostatic precipitator and rotating anode technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode structure, etc., can solve the problems of unguaranteed sealing, single selection, poor dust removal effect, etc., to reduce costs and equipment Uniform distribution of load and current density, effect of reducing materials and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

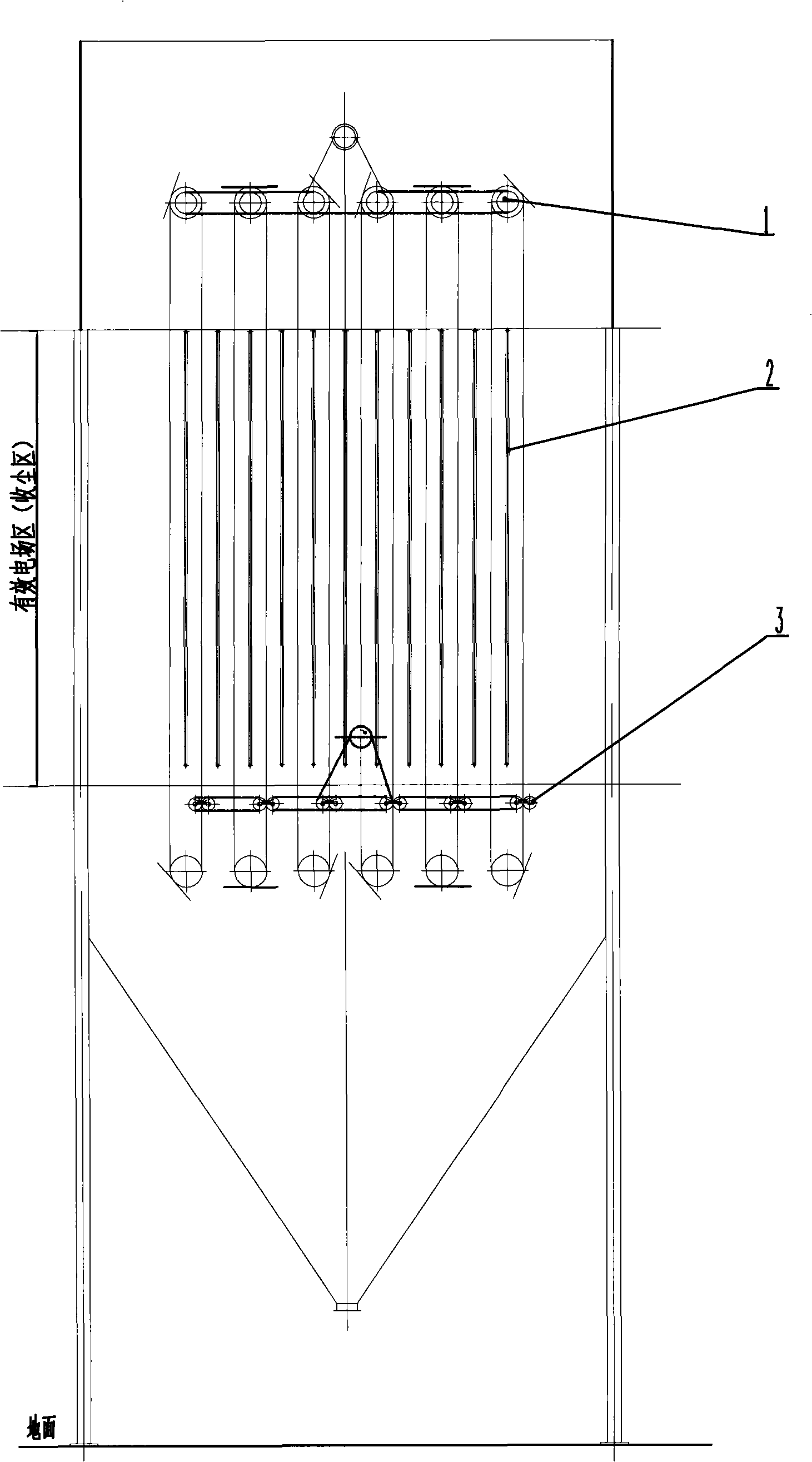

[0032] Such as figure 1 , 2 As shown, the present invention mainly includes a rotary anode device 1, a cathode wire 2 and a rotary steel brush cleaning mechanism 3. The rotary anode device 1 includes a driving roller 5, an anode plate 6, a transmission chain 7 and a driven roller 8, wherein the driving roller 5, the transmission chain 7 and the driven roller 8 form a chain transmission mechanism, and the anode plate 6 is fixed by bolts. On a pair of symmetrical drive chains 7. The reducer 4 provides power to the rotary anode device 1 through a chain drive, so that the anode plate 6 can rotate in a ring along with the transmission chain 7 . The speed of reducer 4 is adjustable; the cathode wire 2 adopts a spiral wire, which is installed in the middle of the anode plate 6, and a high-voltage electric field is applied between the cathode wire 2 and the anode plate 6. When the dust-containing gas enters the electric field, the gas is ionized and the dust is charged. 1. The char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com