Activated carbon fiber-loaded iron doped titanium dioxide photocatalyst and preparation method thereof

A technology of activated carbon fiber and titanium dioxide, which is applied in the field of photocatalyst and its preparation, can solve the problems of secondary pollution, secondary separation, and difficulty in obtaining rare earth elements, and achieves the effect of good reusability and strong ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

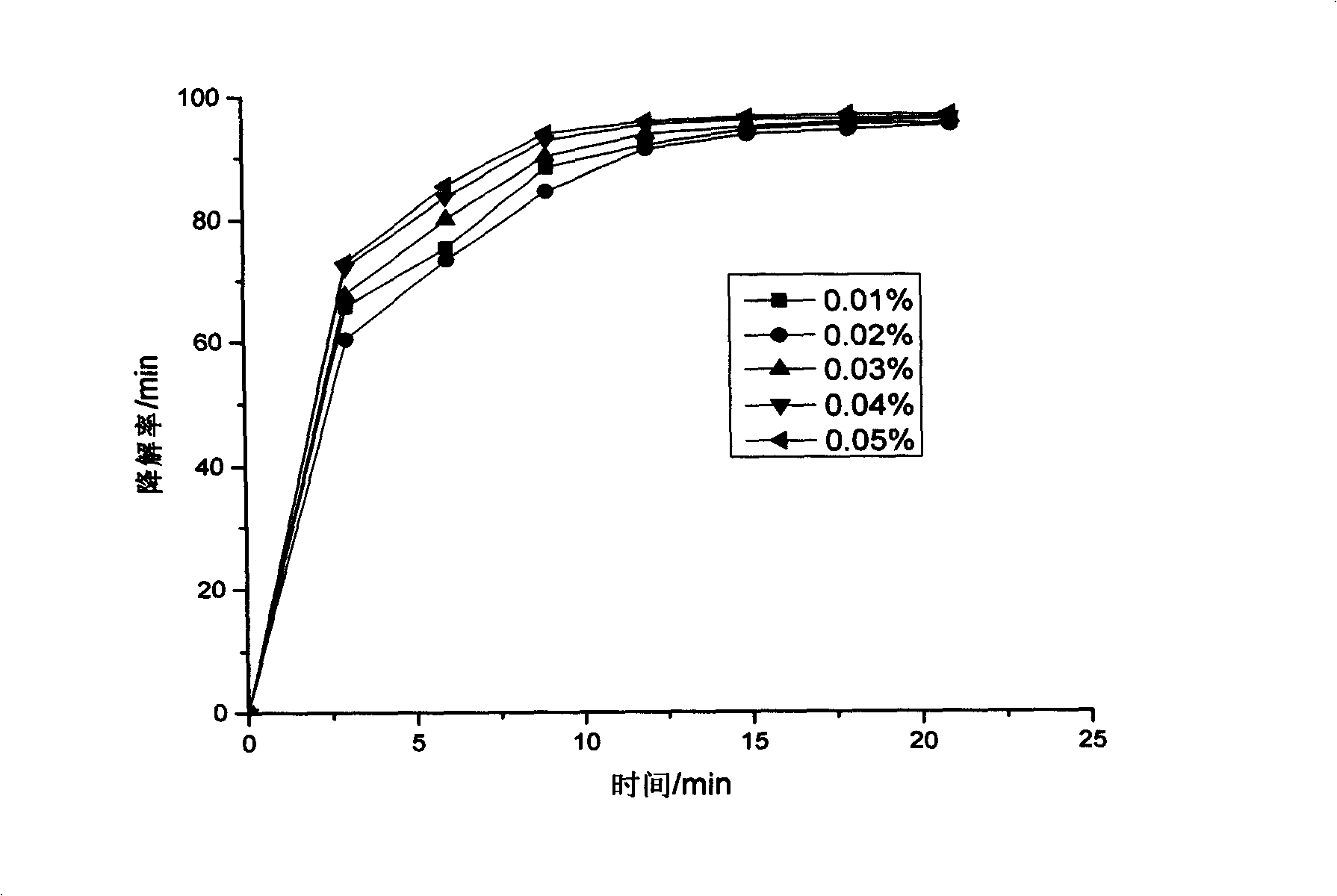

[0058] In this example, the activated carbon fiber-supported iron-doped titanium dioxide photocatalyst was prepared by the sol method, and its degradation effect was verified.

[0059] Including the following steps:

[0060] a. Prepare a sol containing titanium and iron elements;

[0061] b. Pour the sol obtained in step a evenly on the modified and activated activated carbon fiber. After the adsorption is saturated, place it in an oven to dry at 80° C.; after drying, pour the sol to the activated carbon fiber until Adsorption is saturated, and then placed in an oven to dry at 80°C, and this is repeated three times to realize that the titanium-iron composite sol precursor is loaded on the activated carbon fiber;

[0062] c. Transfer the activated carbon fiber loaded with the titanium-iron composite sol precursor into a preheated and dewatered carbonization activation furnace, pass through nitrogen purge and slowly raise the temperature to 80°C to volatilize and remove ethanol...

Embodiment 2

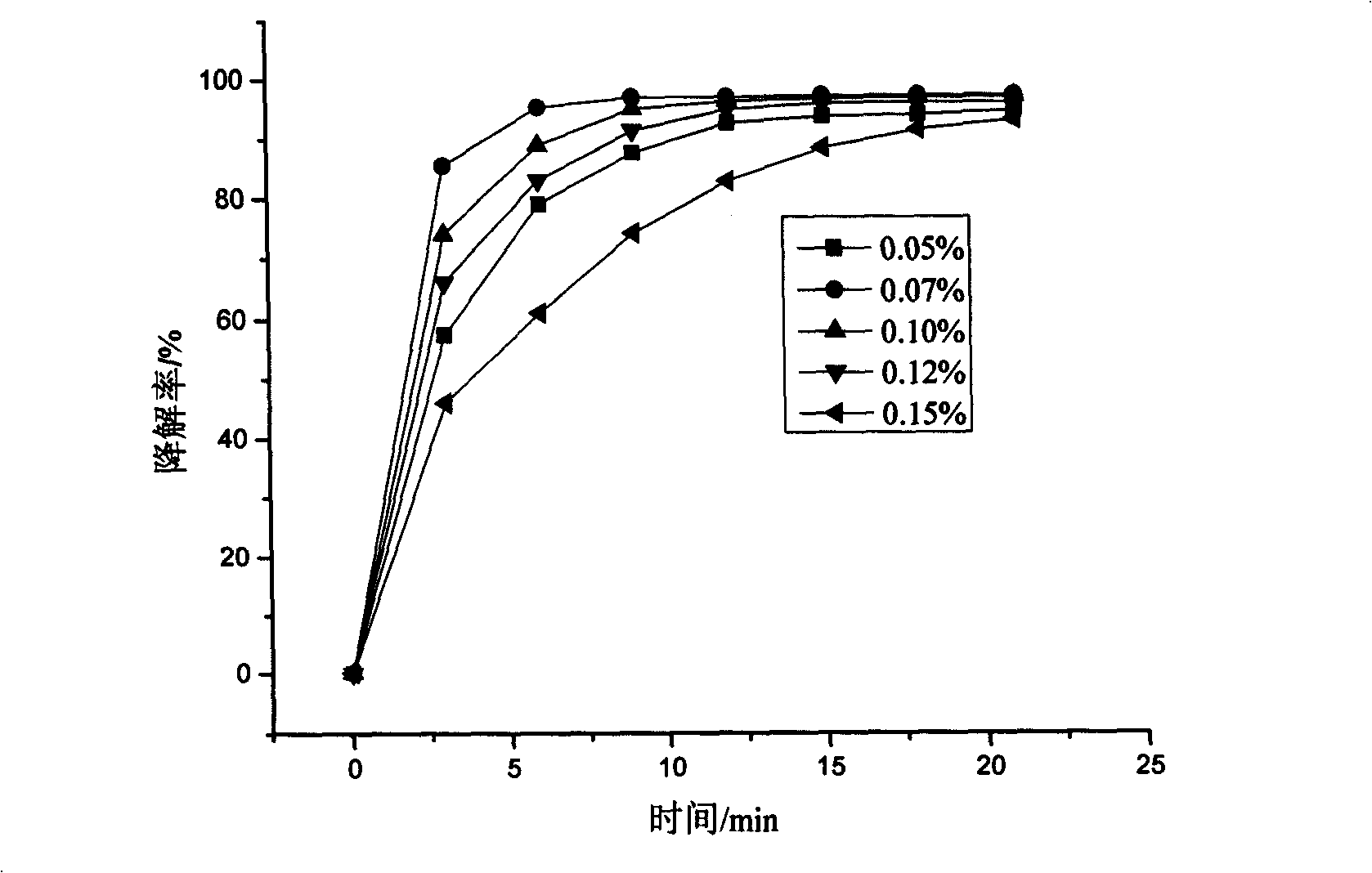

[0087] In this example, the gel method was used to prepare the activated carbon fiber-supported iron-doped titanium dioxide photocatalyst, and its degradation effect was verified.

[0088] Including the following steps:

[0089] a. Prepare a sol containing titanium and iron elements;

[0090] b. the sol obtained in step a is coated on the activated carbon fiber by dipping method or spin coating method;

[0091] c. Then put it into an electric oven, adjust the temperature to 60°C, and age for 6 hours;

[0092] d. Take out the titanium-iron composite from the oven, put it into an electric constant temperature vacuum drying oven, adjust the temperature to 80°C and dry it to obtain a xerogel;

[0093] e. Grind the xerogel into powder, pour it into a porcelain ark, put it into a muffle furnace, adjust to the desired calcination temperature of 500°C, and calcine at a constant temperature for 2 hours to obtain a composite photocatalyst of activated carbon fiber loaded with iron-dop...

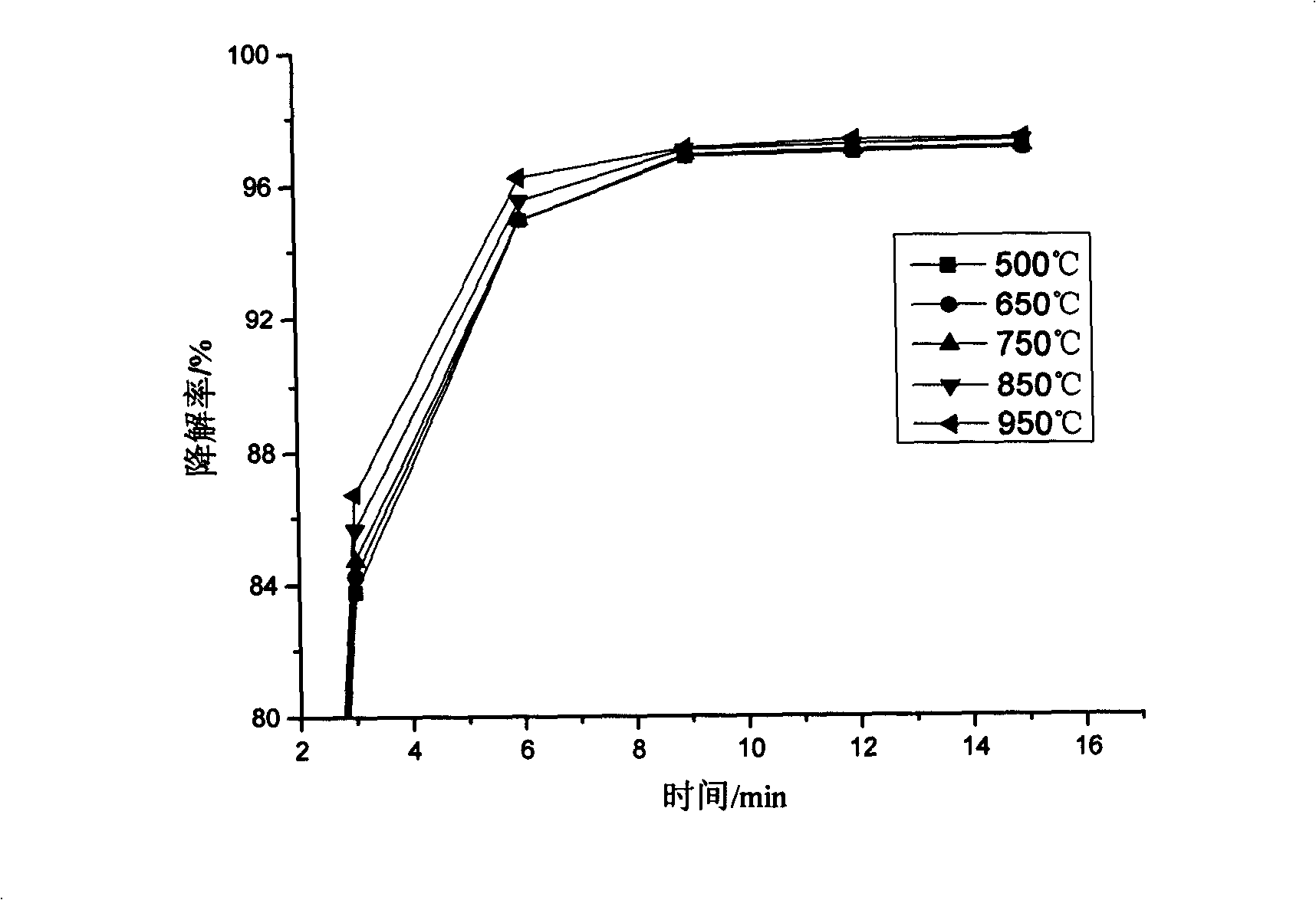

Embodiment 3

[0104] The preparation method of activated carbon fiber loaded iron-doped titanium dioxide photocatalyst is as in Example 1, wherein the mass percentage of iron element in step a2 is 0.07%, the calcination temperature under nitrogen purging in step c is 950 ° C, and the activated carbon fiber is polyacrylonitrile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com