Traction drive of a rail vehicle for driving and generative braking with load correction

A traction drive, power generation braking technology, applied in electric braking systems, brakes, motor vehicles, etc., can solve problems such as low potential for improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

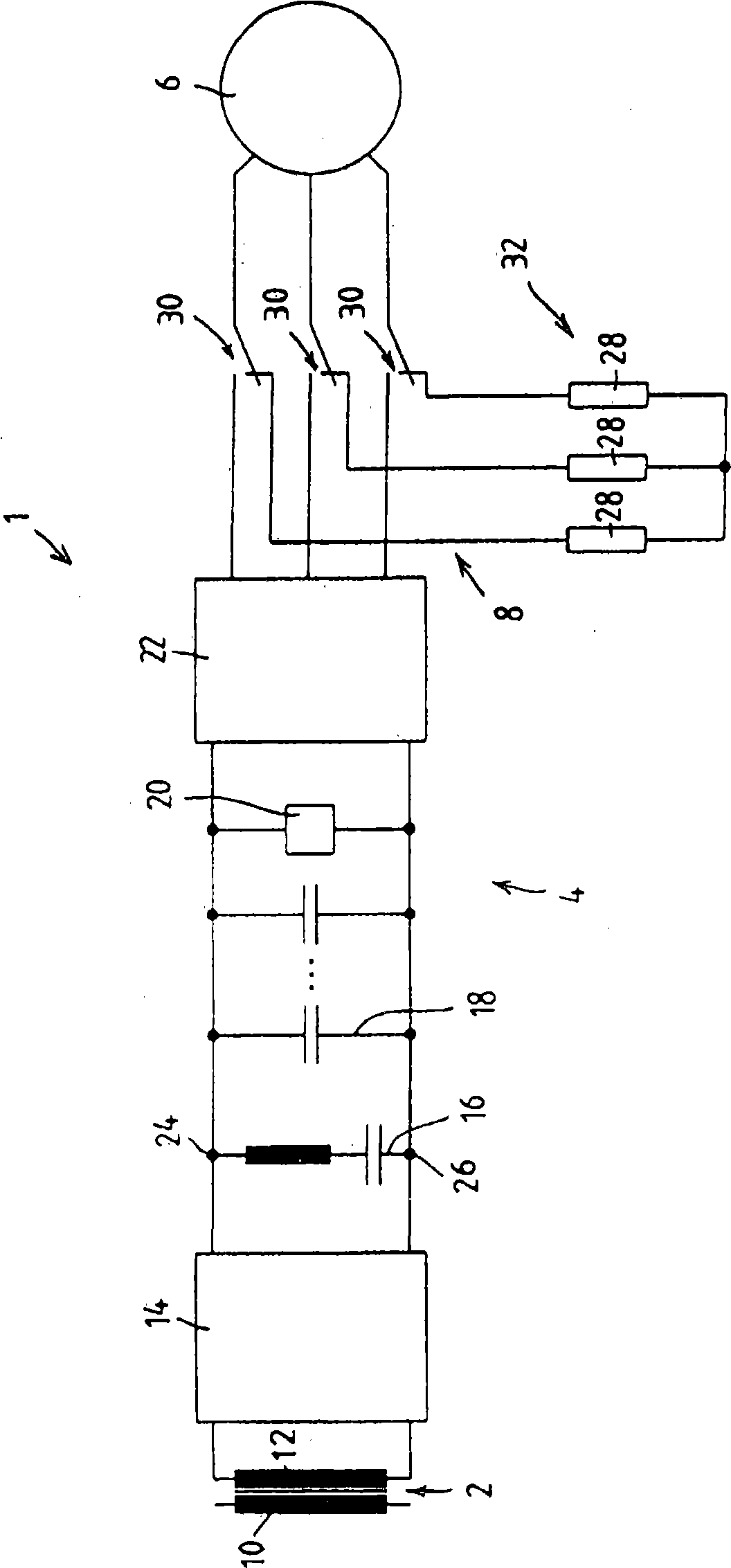

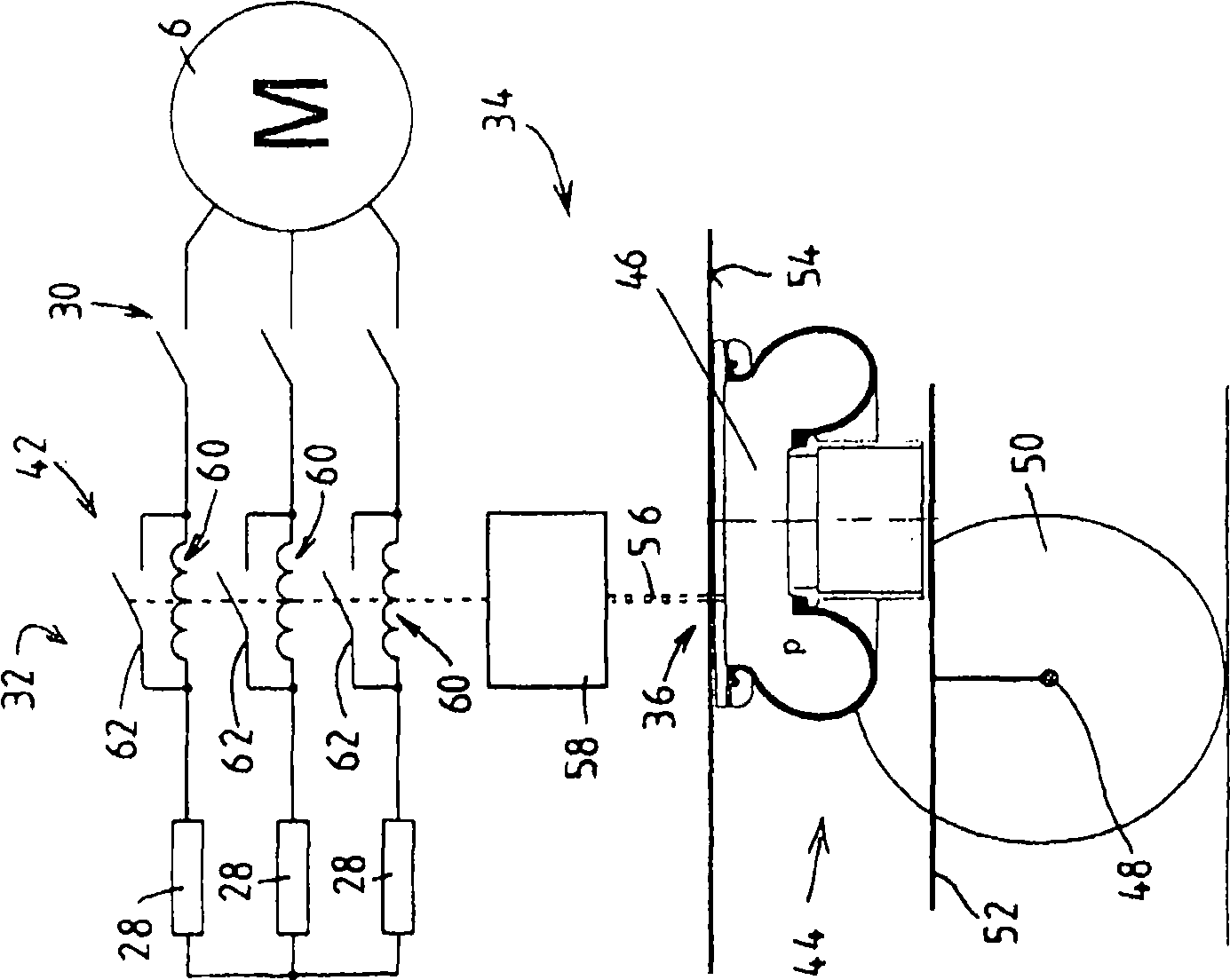

[0043] figure 1The traction drive system 1 for AC trams (also known as AC rail vehicles) is shown in detail in , where 2 represents a traction transformer, 4 represents a traction converter, and 6 represents a permanent magnet excitation synchronous motor , with 8 representing a braking device. The traction transformer 2 has a primary winding 10 and a plurality of secondary windings 12, only one of which is shown here. The traction converter 4 has a four-quadrant regulator 14 , a snubber circuit 16 , a capacitor battery 18 , an overvoltage protection device 20 and a pulse converter 22 on the machine side. The four-quadrant regulator 14 is connected to the secondary winding 12 of the traction transformer 2 on the AC voltage side and in parallel circuit connection on the DC voltage side. The absorber circuit 16 , the capacitor battery 18 , the overvoltage protection device 20 and the DC voltage-side input connection of the motor-side pulse converter 22 are connected in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com