Environmental protection glass-reinforced plastic pipe and production method thereof

A technology of FRP and FRP, applied to pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of oil resource consumption, environmental pollution, etc., and achieve the effects of saving oil resources, low cost, and increasing farmers' income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

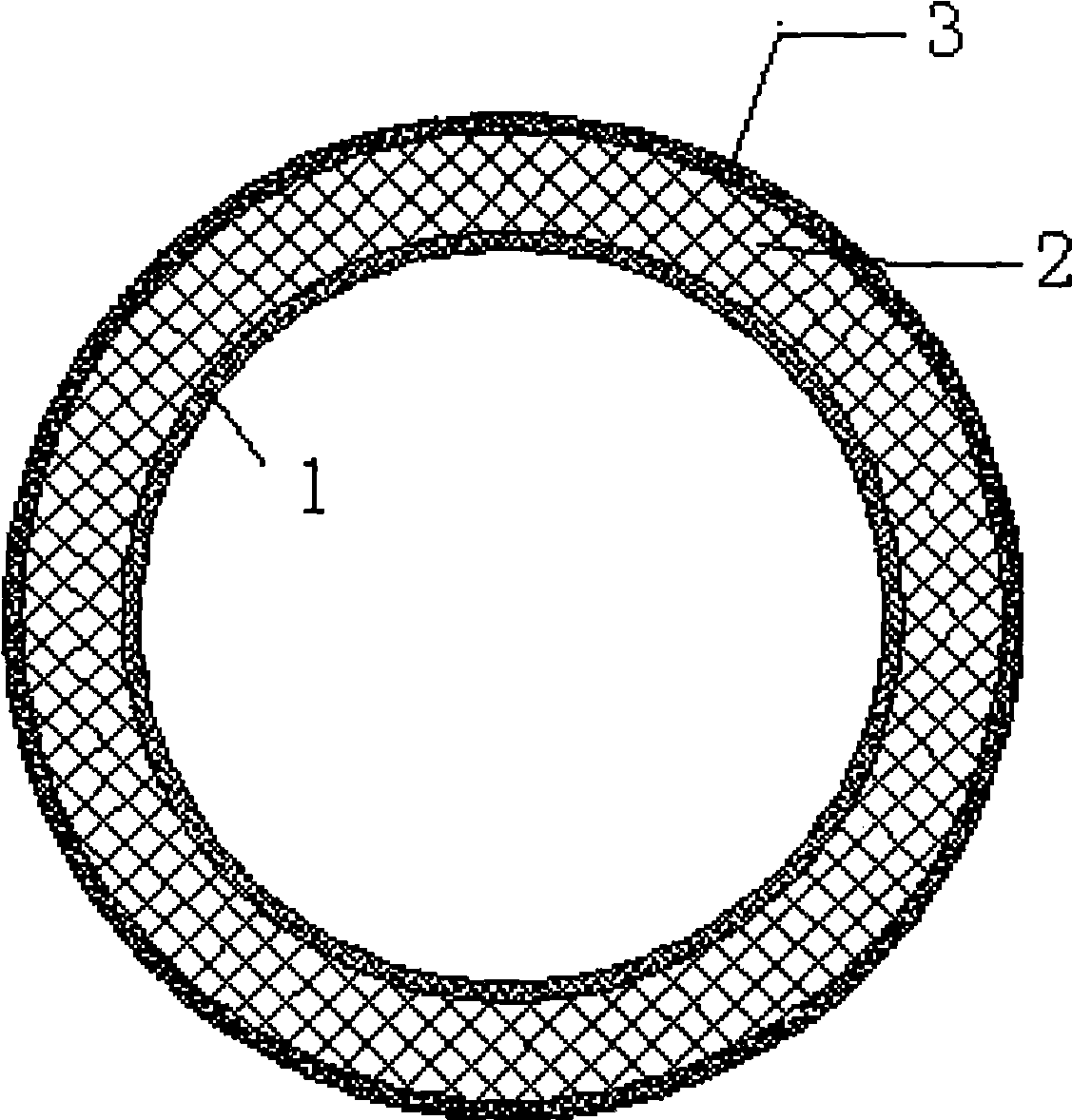

Image

Examples

Embodiment 1

[0026] Taking the DN200 FRP pipe as an example, the implementation steps are as follows:

[0027] a) FRP inner lining preparation process:

[0028] A polished steel straight pipe mold with an outer diameter of 200mm is covered with a layer of release film (polyester), and a vinyl ester resin (Changzhou Tianma) with excellent anti-corrosion performance and a glass fiber surface felt (36g / m2) are used in the mold. Make an inner lining layer with a thickness of 2mm on the pipe mold;

[0029] b) bamboo chip pretreatment process:

[0030] Cut fresh moso bamboo into 5-meter-long, 10mm-wide, and 0.6mm-thick bamboo slices, soak them in 15% NaOH solution at 60°C for 40 minutes, dry until the moisture content is 15%, and glue the bamboo slices with 502 glue. Glue the front and back to form continuous bamboo strips, and roll them on the reel for use;

[0031] c) winding process:

[0032] After the lining layer is cured, put the pre-rolled bamboo slices on the winding machine, unwind ...

Embodiment 2

[0037] Taking the DN100 glass steel pipe as an example, the implementation steps are as follows:

[0038] a) FRP inner lining preparation process:

[0039] A polished steel straight pipe mold with an outer diameter of 200mm is covered with a layer of release film (polyester), and a vinyl ester resin (Changzhou Tianma) with excellent anti-corrosion performance and a glass fiber surface mat (36g / m 2 ) making an inner liner with a thickness of up to 2mm on the pipe mould;

[0040] b) the bamboo chip pretreatment process is:

[0041] Cut fresh moso bamboo into bamboo slices 2 meters long, 8mm wide, and 0.5mm thick, soak them in 12% NaOH solution at 50°C for 30 minutes, dry until the moisture content is 10%, and glue the bamboo slices with 502 glue. Glue the front and back to form continuous bamboo strips, and roll them on the reel for use;

[0042] c) winding process:

[0043] After the lining layer is cured, put the pre-rolled bamboo slices on the winding machine, unwind the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com