Automobile exhaust purification method and automobile exhaust purification system thereof

A technology for automobile exhaust and purification systems, applied in chemical instruments and methods, exhaust gas treatment, exhaust devices, etc., can solve the problems of reducing catalytic conversion efficiency on the surface of catalytic materials, achieve the ability to maintain continuous adsorption, easy to use, reduce Effect of harmful substance content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

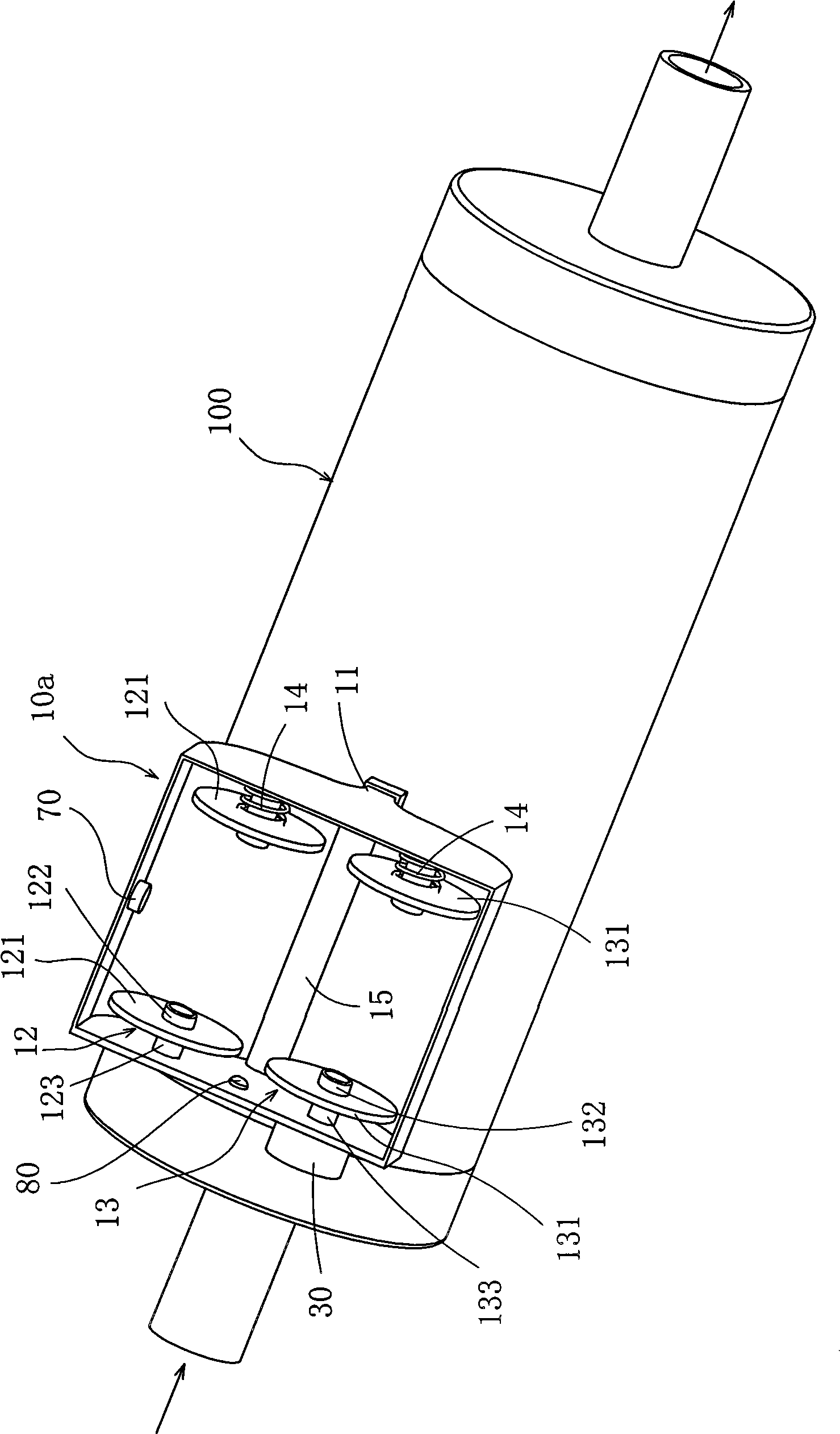

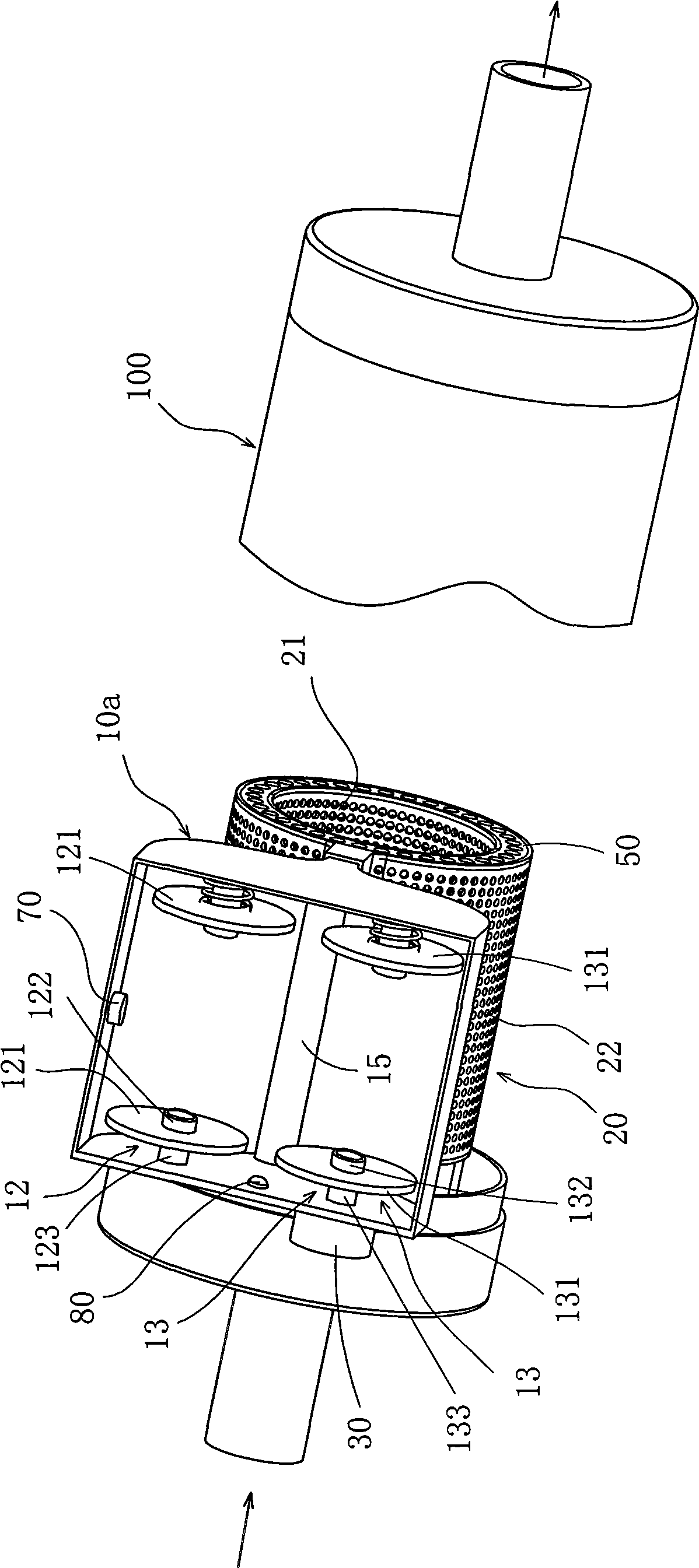

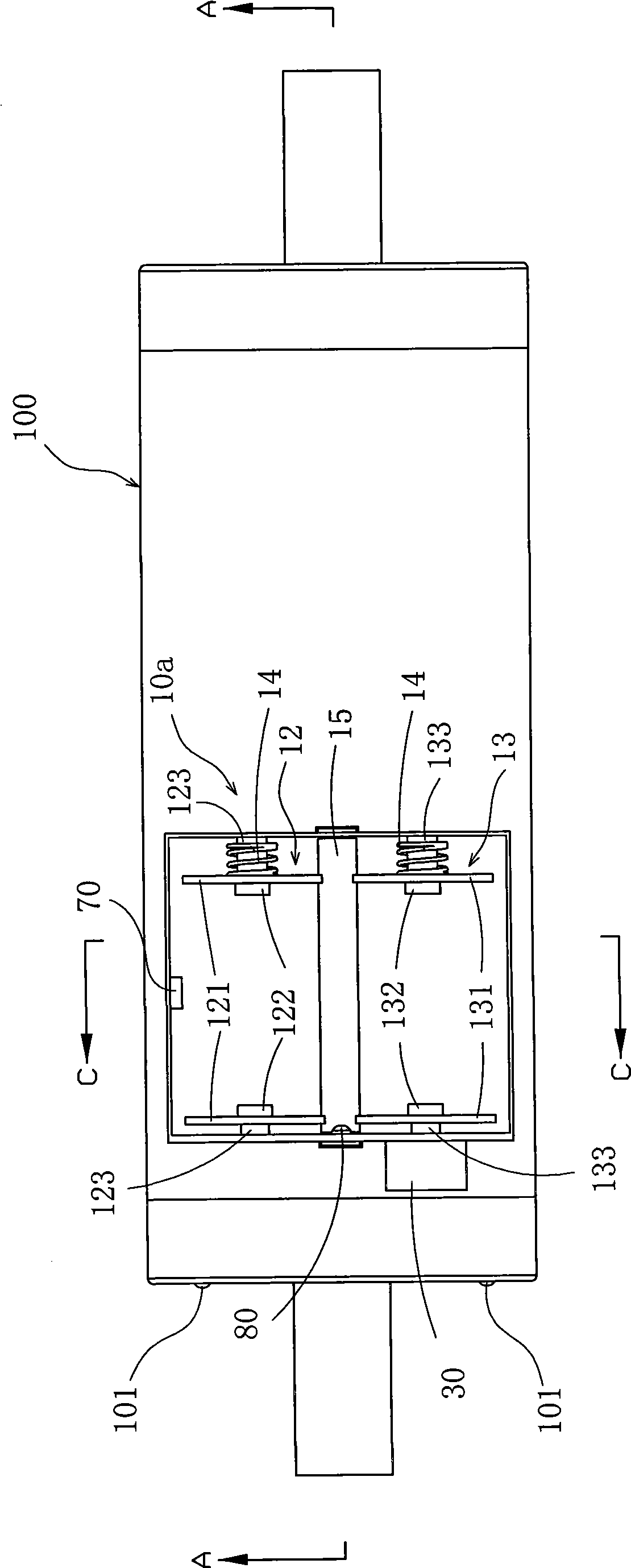

[0051] Such as Figure 1~6 As shown, the automobile exhaust purification system of the present embodiment is contained in the air inlet end of muffler pipe 100, and it comprises casing 10a, carbon paper 41, carbon paper roll 42,43, sensor 70, rolling bar 15, miniature Slow speed motor 30, control circuit, the parts such as the paper tube 20 in the muffler pipe as the indicator light of signal prompting device. The activated carbon paper of the invention adopts the non-woven fabric with high temperature resistance, tensile strength, good permeability and easy degradation as the base material. Among them, the control circuit is set in the appropriate position of the car, for example, it can be set inside the driver's console, or installed with the control circuit of the car, or integrated in the central control system of the car, and the indicator light is set in the cab, such as Figure 7 As shown, the control circuit is electrically connected with the micro slow motor, the se...

Embodiment 2

[0063] Such as Figure 8 As shown, the purification method of this embodiment is the same as that of Embodiment 1, and the system structure is basically the same. The only difference is that the miniature slow-speed motor is arranged on the inner wall of the box body 10a, and the output shaft of the motor is connected with the active carbon paper roll mounting seat. .

Embodiment 3

[0065] Such as Figure 9-10 Shown is embodiment 3 of the present invention, the principle of the purification method of this embodiment and embodiment 2 is the same, the system structure is then basically the same, but the box body adopts two split type box bodies 10b. These two split boxes are parallel to each other and are located above the muffler pipe. They are arranged at a certain distance according to the space under the tail box of the car body. cover. The active mounting base 13 and the passive mounting base 12 are separately installed in two split boxes.

[0066] The opposite inner sides of the bottoms of the two split-type boxes are respectively provided with smooth transitions and horizontally extending belt-shaped tubes 11, the outer ends of the belt-shaped tubes 11 are open, and each belt-shaped tube is respectively sleeved with a heat-insulating fiber or An elastic pipe joint 60 made of metal; a T-shaped tee pipe 16 with two ports 161, 162 on its upper part, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com