Method for preparing Y-shaped carbon nano tube by taking dimethyl sulfide as carbon source

A technology of dimethyl sulfide and carbon nanotubes, applied in the field of preparing Y-type carbon nanotubes, can solve the problems of large change in product morphology, long process flow, difficult to master and control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

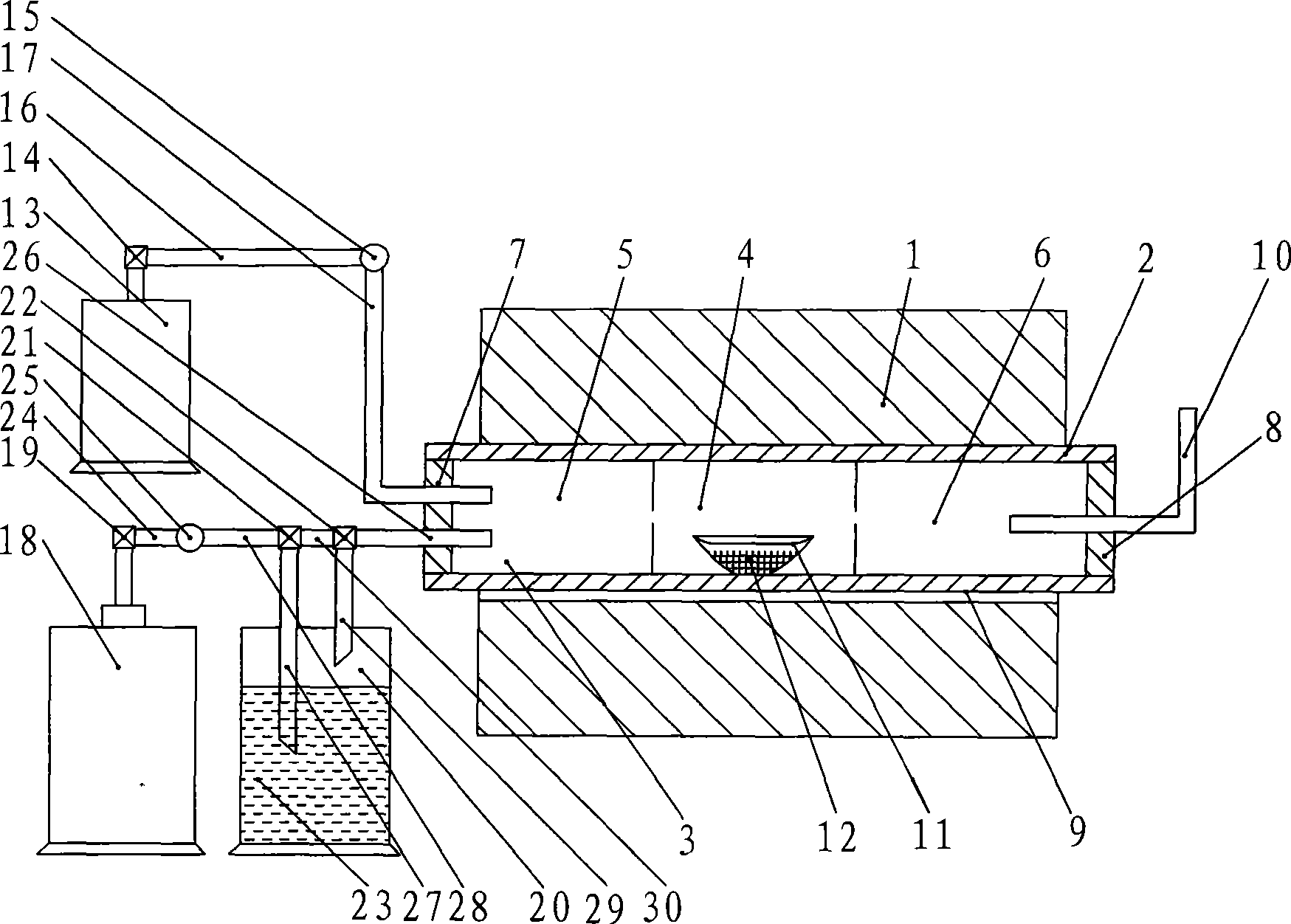

[0095] The present invention will be further described below in conjunction with accompanying drawing:

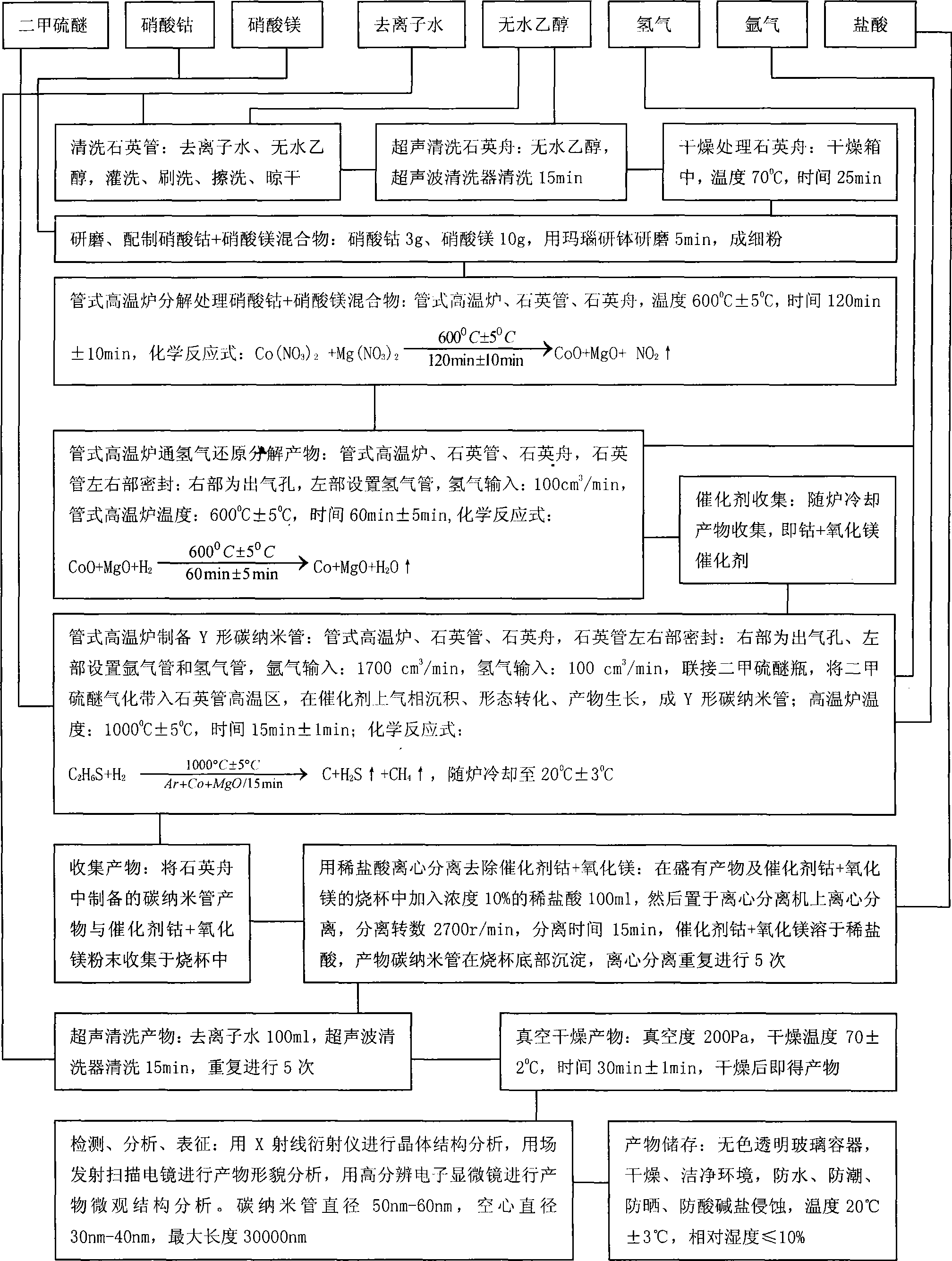

[0096] figure 1 As shown, it is the preparation process flow chart, which must be strictly carried out step by step and operated in sequence.

[0097] Quantities of chemicals required for preparation are determined in pre-set ranges in grams, milliliters, centimeters 3 As a unit of measurement, when it is produced industrially, it is expressed in kilograms, liters, or meters 3 is the unit of measurement.

[0098] Quartz tubes and quartz boats should be cleaned and kept clean to prevent side reactions.

[0099] Beakers, containers, agate mortars, stirrers, ultrasonic cleaners, centrifuges, etc. used for preparation should be kept clean to prevent by-products.

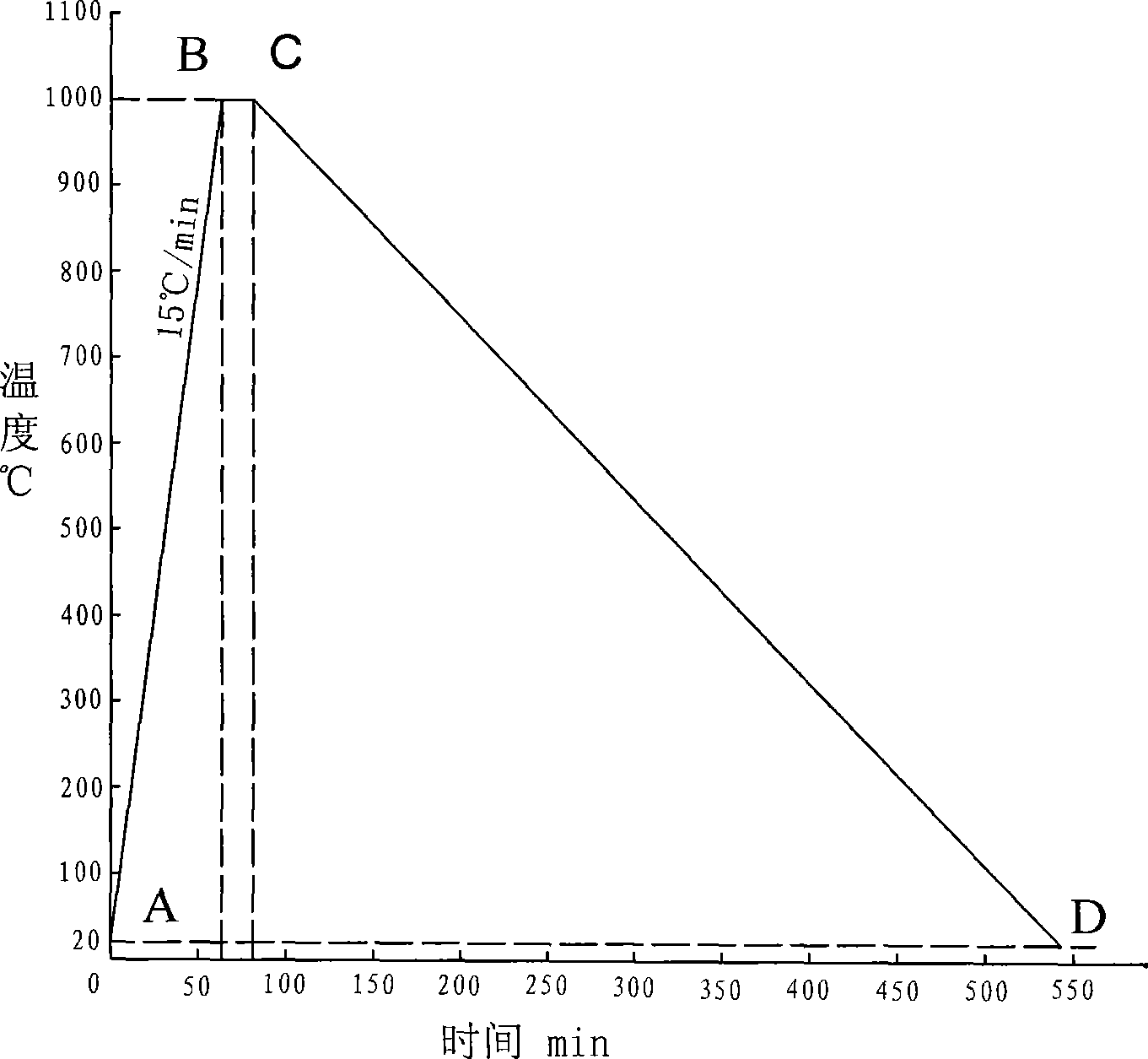

[0100] Cobalt nitrate + magnesium oxide should be ground first, then pyrolysis treatment, 600℃±5℃, time 120min±10min, hydrogen reduction treatment, temperature 600℃±5℃, time 60min±5min, the purpose is to produce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com